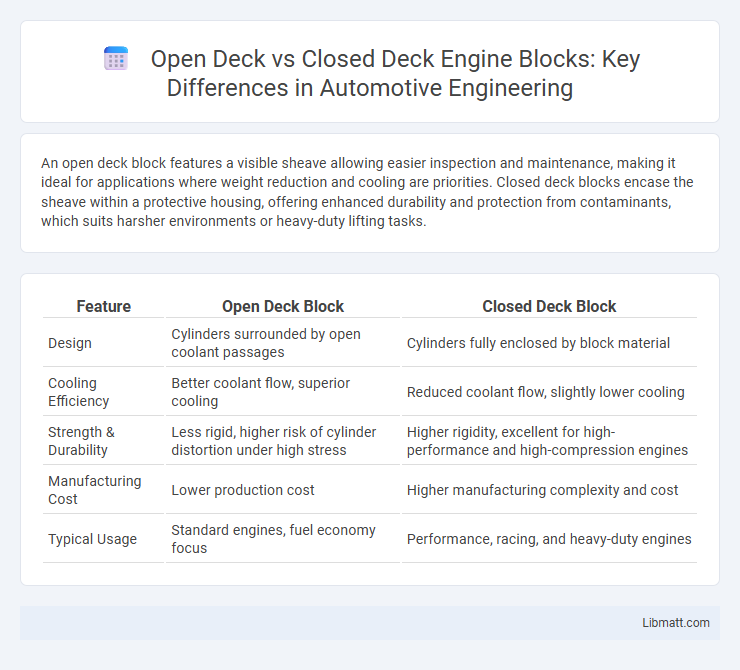

An open deck block features a visible sheave allowing easier inspection and maintenance, making it ideal for applications where weight reduction and cooling are priorities. Closed deck blocks encase the sheave within a protective housing, offering enhanced durability and protection from contaminants, which suits harsher environments or heavy-duty lifting tasks.

Table of Comparison

| Feature | Open Deck Block | Closed Deck Block |

|---|---|---|

| Design | Cylinders surrounded by open coolant passages | Cylinders fully enclosed by block material |

| Cooling Efficiency | Better coolant flow, superior cooling | Reduced coolant flow, slightly lower cooling |

| Strength & Durability | Less rigid, higher risk of cylinder distortion under high stress | Higher rigidity, excellent for high-performance and high-compression engines |

| Manufacturing Cost | Lower production cost | Higher manufacturing complexity and cost |

| Typical Usage | Standard engines, fuel economy focus | Performance, racing, and heavy-duty engines |

Understanding Open Deck and Closed Deck Engine Blocks

Open deck engine blocks feature open spaces around the cylinder walls, allowing improved coolant flow and heat dissipation, which enhances engine cooling performance. Closed deck engine blocks have reinforced cylinder walls with additional material surrounding the cylinders, providing superior structural rigidity and higher resistance to high-pressure combustion, ideal for high-performance and turbocharged engines. Selecting between open deck and closed deck blocks depends on the balance between cooling efficiency and structural strength required for specific engine applications.

Key Structural Differences Between Open and Closed Decks

Open deck blocks feature large, unobstructed spaces beneath the deck surface, allowing for better coolant flow and improved thermal management in engine designs. Closed deck blocks have reinforced areas surrounding the cylinder bores, providing increased strength and rigidity to withstand higher combustion pressures. This structural distinction impacts engine durability, heat dissipation, and the potential for high-performance applications.

Performance Implications: Open Deck vs Closed Deck

Open deck blocks offer superior cooling efficiency due to increased coolant flow around cylinder walls, enhancing thermal management and allowing higher performance tuning. Closed deck blocks provide greater structural rigidity and support for cylinder bores, which improves durability and resistance to high-pressure combustion in forced induction engines. Performance optimization depends on balancing cooling benefits of open deck designs with the strength advantages of closed deck configurations to suit specific engine applications.

Cooling Efficiency in Open vs Closed Deck Designs

Open deck engine blocks offer superior cooling efficiency due to enhanced coolant flow around the cylinder liners, allowing heat to dissipate more rapidly and reducing the risk of overheating. Closed deck designs provide increased structural strength and rigidity but typically restrict coolant flow, which can lead to less efficient heat transfer. Optimizing cooling channels and selecting materials with high thermal conductivity in both designs is essential for maintaining engine performance and longevity.

Durability and Strength: Which Deck Type Lasts Longer?

Open deck blocks offer enhanced durability and strength due to their superior coolant flow and reduced heat buildup, which minimizes engine wear over time. Closed deck blocks provide increased structural rigidity, making them ideal for high-performance applications where maximum engine block strength is essential. Your choice depends on balancing long-term durability with the need for extra strength under high stress conditions.

Cost Considerations: Manufacturing and Maintenance

Open deck engine blocks generally offer lower manufacturing costs due to simpler casting processes and easier access to internal components, reducing machining time and tooling complexity. Closed deck blocks, while more expensive to produce because of reinforced structures and intricate casting designs, provide enhanced durability and better thermodynamic efficiency, potentially lowering long-term maintenance expenses. Your choice between the two impacts both upfront investment and ongoing repair costs, with open deck favoring initial affordability and closed deck supporting long-term reliability.

Suitability for High-Performance and Turbocharged Engines

Open deck blocks offer superior cooling efficiency due to increased coolant flow around the cylinder walls, making them ideal for high-performance and turbocharged engines that generate significant heat. Closed deck blocks provide enhanced structural rigidity and reduced cylinder bore distortion under high boost pressure, supporting greater engine durability and performance in forced induction applications. Engine builders often choose closed deck designs for turbocharged setups to ensure improved strength and reliability during high-power output.

Common Applications and Automotive Uses

Open deck blocks are commonly used in passenger vehicles and light trucks where improved cooling and ease of maintenance are essential, supporting efficient heat dissipation around the cylinders. Closed deck blocks find their application in high-performance and heavy-duty vehicles, including sports cars and commercial trucks, due to their enhanced structural rigidity and ability to withstand higher combustion pressures. You should consider your vehicle's intended use and performance requirements when selecting between open deck and closed deck engine blocks.

Pros and Cons Summary: Open Deck vs Closed Deck

Open deck engine blocks offer superior cooling efficiency due to increased coolant flow around the cylinders, making them ideal for high-performance or heavy-duty applications. Closed deck blocks provide enhanced structural rigidity and support, reducing cylinder distortion under high boost or stress but may suffer from less effective cooling. Your choice depends on balancing cooling needs with durability requirements for your specific engine performance goals.

Choosing the Right Engine Block for Your Build

Open deck engine blocks offer improved coolant flow around the cylinders, making them ideal for high-performance builds that require better cooling and higher horsepower. Closed deck blocks provide superior rigidity and strength, enhancing durability and resistance to cylinder wall distortion under extreme boost or high-compression setups. Selecting the right engine block depends on your build goals: open deck for maximum cooling efficiency and power potential, or closed deck for increased structural integrity and reliability in demanding applications.

open deck vs closed deck block Infographic

libmatt.com

libmatt.com