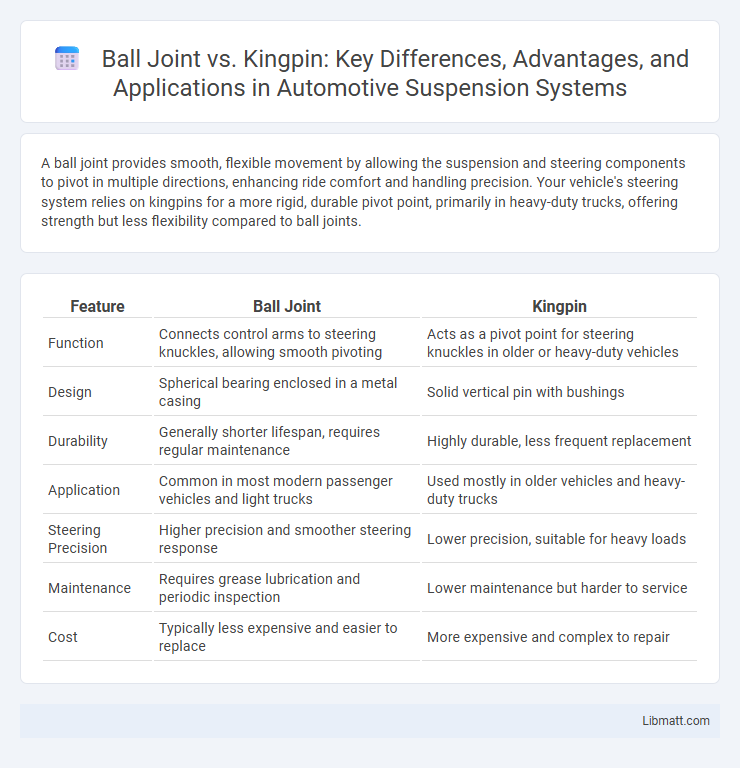

A ball joint provides smooth, flexible movement by allowing the suspension and steering components to pivot in multiple directions, enhancing ride comfort and handling precision. Your vehicle's steering system relies on kingpins for a more rigid, durable pivot point, primarily in heavy-duty trucks, offering strength but less flexibility compared to ball joints.

Table of Comparison

| Feature | Ball Joint | Kingpin |

|---|---|---|

| Function | Connects control arms to steering knuckles, allowing smooth pivoting | Acts as a pivot point for steering knuckles in older or heavy-duty vehicles |

| Design | Spherical bearing enclosed in a metal casing | Solid vertical pin with bushings |

| Durability | Generally shorter lifespan, requires regular maintenance | Highly durable, less frequent replacement |

| Application | Common in most modern passenger vehicles and light trucks | Used mostly in older vehicles and heavy-duty trucks |

| Steering Precision | Higher precision and smoother steering response | Lower precision, suitable for heavy loads |

| Maintenance | Requires grease lubrication and periodic inspection | Lower maintenance but harder to service |

| Cost | Typically less expensive and easier to replace | More expensive and complex to repair |

Introduction to Ball Joint and Kingpin Systems

Ball joint systems provide pivotal connections between vehicle suspension and steering components, enabling smooth articulation and improved handling. Kingpin systems consist of a vertical axle pin that acts as a pivot in older or heavy-duty vehicles, offering robust steering control and durability. Understanding the distinct mechanical functions and applications of ball joints versus kingpins is essential for optimizing suspension design and vehicle performance.

Historical Development of Ball Joints and Kingpins

The historical development of ball joints dates back to early 20th-century automotive suspension systems, where they replaced kingpins to improve steering flexibility and reduce wear. Kingpins, used primarily in vintage vehicles and heavy-duty trucks, functioned as a solid pivot point but often led to increased friction and maintenance challenges. Your understanding of these components highlights how ball joints revolutionized vehicle handling by offering smoother articulation compared to the more rigid kingpin design.

Structural Differences Between Ball Joints and Kingpins

Ball joints connect the control arms to the steering knuckles using a spherical bearing, allowing multidirectional movement crucial for smooth steering and suspension articulation. Kingpins, typically found in older or heavy-duty vehicles, serve as a pivot point secured by a vertical pin through the steering knuckle and axle spindle, offering a more rigid connection but less flexibility compared to ball joints. Understanding these structural differences helps you evaluate vehicle handling performance and maintenance requirements effectively.

Functionality and How Each System Works

Ball joint systems enable smooth multidirectional movement by connecting the control arms to the steering knuckles, allowing precise wheel articulation and suspension flexibility. Kingpin systems use a fixed vertical pin housed in the steering knuckle to pivot the wheel, providing sturdy axial support but limiting steering range compared to ball joints. The ball joint design enhances vehicle handling and ride comfort, while kingpins offer durability suited for heavy-duty applications and older vehicle models.

Advantages of Ball Joint Suspension

Ball joint suspension offers superior flexibility and smoother steering control compared to kingpin setups, enhancing overall vehicle handling and ride comfort. It reduces friction and wear due to its design, leading to longer service life and lower maintenance costs. You benefit from improved alignment precision, which contributes to better tire wear and fuel efficiency.

Benefits of the Kingpin Suspension Design

Kingpin suspension design offers superior durability and enhanced steering precision compared to ball joint setups, making it ideal for heavy-duty and off-road vehicles. It provides a more robust pivot point that reduces wear and extends the lifespan of suspension components. Your vehicle benefits from improved alignment stability and better handling under extreme conditions with kingpin suspension systems.

Common Applications: Ball Joint vs Kingpin

Ball joints are commonly used in independent front suspension systems of passenger vehicles, allowing smooth movement and steering flexibility. Kingpins are typically found in heavy-duty trucks and older vehicle models, serving as a pivot point for the steering knuckle in solid axle setups. The choice between ball joint and kingpin depends on vehicle design, load capacity, and suspension type requirements.

Maintenance Requirements and Durability

Ball joints require regular lubrication and periodic inspections to prevent wear and maintain smooth steering performance, making maintenance more frequent compared to kingpins. Kingpins, typically used in heavy-duty and older vehicles, offer superior durability and can withstand higher loads but may demand more complex servicing when wear occurs. Understanding your vehicle's suspension type helps optimize maintenance schedules and extend component lifespan effectively.

Performance Comparison: Handling and Ride Quality

Ball joints provide precise steering control and smoother ride quality due to their ability to flex in multiple directions, enhancing handling on varied road surfaces. Kingpins offer robust durability and stability, favored for heavy-duty applications, but may result in a firmer ride with less responsiveness. Your choice between ball joints and kingpins directly impacts vehicle handling dynamics and overall ride comfort.

Choosing the Right System: Factors to Consider

Selecting between a ball joint and kingpin system requires evaluating vehicle type, load capacity, and steering precision needs. Ball joints offer enhanced articulation and smoother handling, ideal for modern passenger cars, while kingpins provide durability and robustness suited for heavy-duty trucks. Consider maintenance frequency and replacement costs to ensure optimal performance and longevity in specific driving conditions.

Ball Joint vs Kingpin Infographic

libmatt.com

libmatt.com