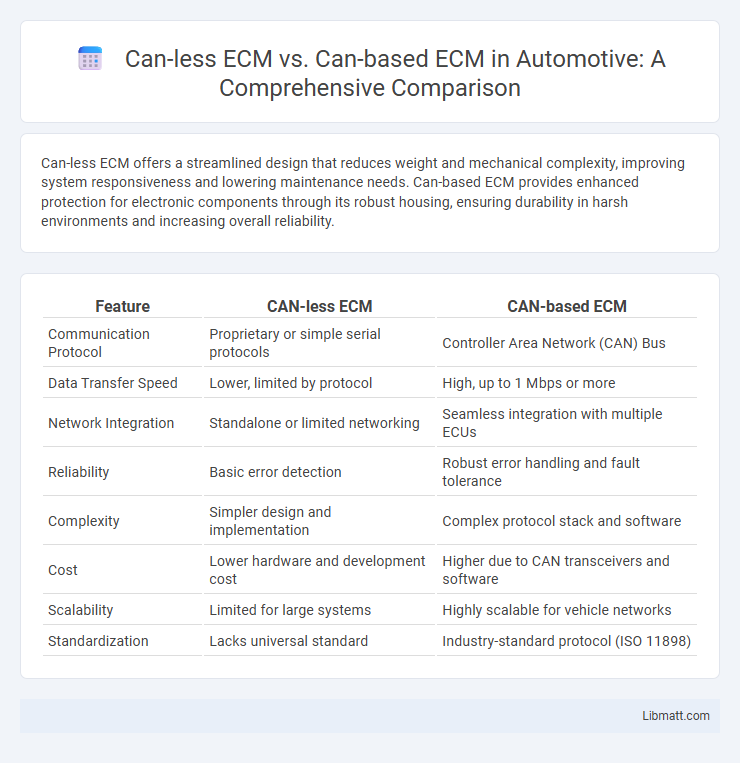

Can-less ECM offers a streamlined design that reduces weight and mechanical complexity, improving system responsiveness and lowering maintenance needs. Can-based ECM provides enhanced protection for electronic components through its robust housing, ensuring durability in harsh environments and increasing overall reliability.

Table of Comparison

| Feature | CAN-less ECM | CAN-based ECM |

|---|---|---|

| Communication Protocol | Proprietary or simple serial protocols | Controller Area Network (CAN) Bus |

| Data Transfer Speed | Lower, limited by protocol | High, up to 1 Mbps or more |

| Network Integration | Standalone or limited networking | Seamless integration with multiple ECUs |

| Reliability | Basic error detection | Robust error handling and fault tolerance |

| Complexity | Simpler design and implementation | Complex protocol stack and software |

| Cost | Lower hardware and development cost | Higher due to CAN transceivers and software |

| Scalability | Limited for large systems | Highly scalable for vehicle networks |

| Standardization | Lacks universal standard | Industry-standard protocol (ISO 11898) |

Introduction to ECM Technologies

Can-less ECM technology eliminates the need for a sealed metal enclosure, relying on robust internal components to protect electronic modules, which reduces size and weight in advanced automotive systems. Can-based ECM utilizes a metal can casing to shield internal circuits from electromagnetic interference, providing enhanced durability in harsh environments. Understanding these distinctions helps you choose the most suitable ECM type based on your application's performance and protection requirements.

Understanding Can-less ECM Systems

Can-less ECM systems eliminate the Controller Area Network (CAN) bus, relying instead on direct communication protocols like Ethernet or FlexRay for faster and more reliable data exchange. These systems offer reduced wiring complexity and lower electromagnetic interference compared to traditional CAN-based ECMs, enhancing overall vehicle network performance. By leveraging high-speed data transfer capabilities, Can-less ECMs improve diagnostics, control precision, and real-time response in modern automotive applications.

What are Can-based ECM Solutions?

Can-based ECM solutions utilize Controller Area Network (CAN) protocols to enable real-time communication between electronic control modules in vehicles, ensuring reliable data exchange across multiple components. These systems offer enhanced diagnostic capabilities, improved vehicle performance monitoring, and seamless integration with automotive networks. Your choice of Can-based ECM ensures efficient control and coordination of engine functions through standardized communication protocols.

Key Differences Between Can-less and Can-based ECM

Can-based ECM (Electrochemical Machining) relies on a conductive container (can) to confine the electrolyte and shape the electric field, ensuring precise material removal and enhanced surface finish control. Can-less ECM eliminates the need for the conductive container by using alternative methods such as pressurized electrolyte flow or specifically designed tool electrodes to maintain the machining gap and electrolyte circulation. Key differences include the complexity and cost of tooling, electrolyte management, and the achievable cavity geometries, with can-less ECM offering greater flexibility in machining intricate shapes but requiring more sophisticated process control.

Performance Comparison: Can-less vs Can-based ECM

Can-based ECM systems generally offer higher reliability and real-time performance due to their robust error detection and message prioritization features, making them suitable for complex automotive and industrial applications. Can-less ECMs, while simpler and more cost-effective, may struggle with latency and data integrity in high-traffic environments, potentially affecting overall system responsiveness. Your choice depends on whether peak performance and fault tolerance or budget and simplicity align better with your application requirements.

Installation and Integration Considerations

Can-less ECM systems offer simplified installation by eliminating the need for a Controller Area Network (CAN) interface, reducing wiring complexity and enabling faster integration into existing setups. Can-based ECMs require careful configuration of the CAN bus, including proper termination and network addressing, which can extend installation time and increase the need for specialized tools. Your choice impacts not only setup efficiency but also future scalability and compatibility with vehicle or equipment communication protocols.

Cost Implications: Can-less vs Can-based ECM

Can-less ECM systems reduce costs significantly by eliminating the need for metal can packaging, which lowers material and manufacturing expenses. Can-based ECM involves additional expenses due to the use of cans for protection and heat dissipation, increasing overall production and shipping costs. Your choice between can-less and can-based ECM impacts budget allocation, with can-less offering a more cost-effective solution in applications where enhanced protection is not critical.

Maintenance and Reliability Factors

Can-less ECM systems eliminate the canister, reducing maintenance tasks such as seal replacements and potential leak points common in Can-based ECMs. Reliability in can-less designs improves due to fewer components subject to wear, minimizing downtime and enhancing system longevity. Conversely, Can-based ECMs require regular inspection and maintenance of the canister to prevent contamination and mechanical failures, impacting overall system reliability.

Application Suitability and Use Cases

Can-less ECM systems excel in lightweight applications such as small-scale consumer electronics and basic IoT devices due to their reduced complexity and lower cost. Can-based ECM solutions are preferred for automotive, industrial, and aerospace applications where robust communication, fault tolerance, and real-time data exchange over the Controller Area Network (CAN) bus are critical. The choice between Can-less and Can-based ECM hinges on factors including system complexity, real-time performance requirements, and environmental robustness.

Future Trends in ECM Technology

Future trends in ECM technology indicate a shift towards can-less ECM systems, driven by advancements in integrated circuit design and the demand for more compact, lightweight automotive components. Can-less ECMs offer improved thermal management and faster data processing by eliminating traditional metal-can packaging, allowing enhanced reliability and performance in electric and autonomous vehicles. Your choice of ECM technology will influence the scalability and adaptability of vehicle control units as the industry moves towards connected and AI-driven powertrain management solutions.

Can-less ECM vs Can-based ECM Infographic

libmatt.com

libmatt.com