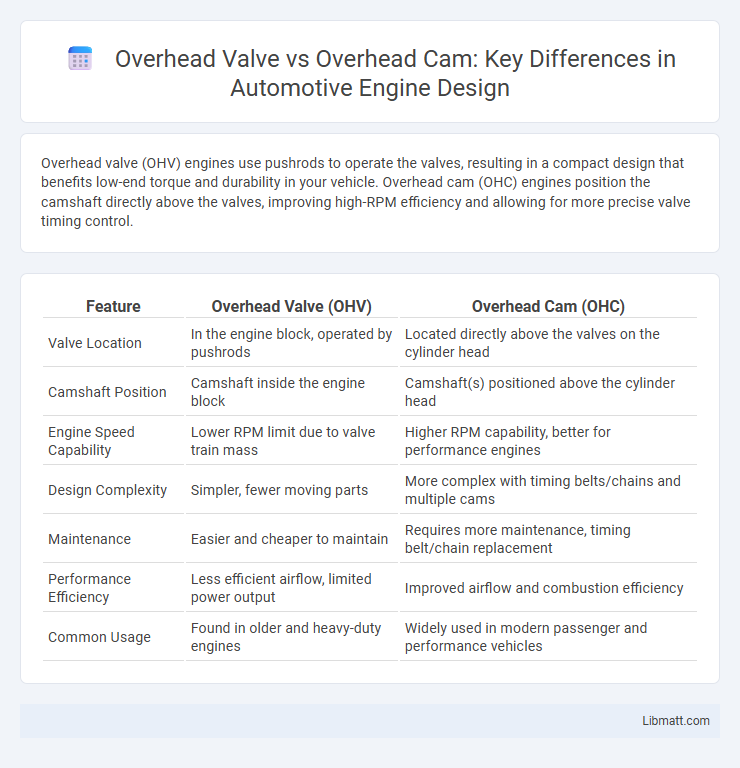

Overhead valve (OHV) engines use pushrods to operate the valves, resulting in a compact design that benefits low-end torque and durability in your vehicle. Overhead cam (OHC) engines position the camshaft directly above the valves, improving high-RPM efficiency and allowing for more precise valve timing control.

Table of Comparison

| Feature | Overhead Valve (OHV) | Overhead Cam (OHC) |

|---|---|---|

| Valve Location | In the engine block, operated by pushrods | Located directly above the valves on the cylinder head |

| Camshaft Position | Camshaft inside the engine block | Camshaft(s) positioned above the cylinder head |

| Engine Speed Capability | Lower RPM limit due to valve train mass | Higher RPM capability, better for performance engines |

| Design Complexity | Simpler, fewer moving parts | More complex with timing belts/chains and multiple cams |

| Maintenance | Easier and cheaper to maintain | Requires more maintenance, timing belt/chain replacement |

| Performance Efficiency | Less efficient airflow, limited power output | Improved airflow and combustion efficiency |

| Common Usage | Found in older and heavy-duty engines | Widely used in modern passenger and performance vehicles |

Introduction to Valve Train Designs

Overhead Valve (OHV) engines utilize a camshaft located within the engine block, operating valves through pushrods and rocker arms, creating a compact and durable valve train design ideal for torque-focused applications. Overhead Camshaft (OHC) engines position the camshaft directly above the valves in the cylinder head, allowing for more precise valve timing, higher engine speeds, and improved efficiency. These differences in valve train architecture significantly impact engine performance, maintenance, and overall design complexity.

What is an Overhead Valve (OHV) Engine?

An Overhead Valve (OHV) engine features its camshaft located within the engine block, using pushrods to operate the valves positioned above the combustion chamber. This design offers a more compact engine layout with fewer moving parts compared to Overhead Cam (OHC) engines, often resulting in improved low-end torque and simpler maintenance. Your choice between OHV and OHC engines will impact factors such as engine size, performance characteristics, and servicing complexity.

Understanding Overhead Camshaft (OHC) Engines

Overhead Camshaft (OHC) engines feature the camshaft positioned above the cylinder head, directly operating the intake and exhaust valves for improved precision and efficiency compared to Overhead Valve (OHV) designs. This configuration reduces valve train components, resulting in higher engine speeds and better fuel economy. OHC engines are favored in modern vehicles due to enhanced performance, smoother operation, and reduced mechanical complexity.

Structural Differences: OHV vs OHC

Overhead Valve (OHV) engines feature the camshaft located within the engine block, using pushrods to actuate the valves situated in the cylinder head, whereas Overhead Cam (OHC) engines position the camshaft directly above the valves, eliminating the need for pushrods. The OHV design typically results in a more compact engine structure and lower overall height, while OHC engines allow for more precise valve timing and higher RPM capabilities due to reduced valvetrain mass. Structural differences impact engine performance, complexity, and maintenance, with OHV being simpler but OHC offering enhanced efficiency and power output.

Performance Comparison: Power and Efficiency

Overhead Valve (OHV) engines typically deliver strong low-end torque due to their shorter valvetrain and compact design, making them efficient for everyday driving and towing. Overhead Cam (OHC) engines, especially Dual Overhead Cam (DOHC) configurations, provide superior high-RPM power and improved efficiency by allowing more precise valve timing and increased airflow. This results in higher horsepower potential and better fuel economy, particularly in performance-oriented and modern vehicles.

Maintenance and Longevity of Each System

Overhead Valve (OHV) engines typically require more frequent valve adjustments due to their pushrod design, which can increase maintenance intervals compared to Overhead Cam (OHC) engines that have fewer moving parts in the valvetrain. OHC systems benefit from more precise valve timing and less mechanical complexity, contributing to longer engine longevity and reduced wear over time. While OHV engines are renowned for durability and simplicity, OHC engines often deliver better performance and lower maintenance costs through modern engineering advancements.

Cost Implications: Manufacturing and Repairs

Overhead Valve (OHV) engines generally have lower manufacturing costs due to their simpler design with fewer moving parts compared to Overhead Cam (OHC) engines, which require more precision components and advanced materials. Repair and maintenance expenses for OHV engines tend to be less costly, as their components are easier to access and replace, whereas OHC engines often demand specialized tools and expertise, increasing labor costs. Choosing between OHV and OHC designs impacts your long-term budget, balancing initial affordability against potential maintenance complexity.

Applications: Popular Uses in Modern Engines

Overhead Valve (OHV) engines are commonly found in trucks and muscle cars due to their robust low-end torque and simpler design, making them ideal for heavy-duty applications and performance-oriented vehicles. Overhead Cam (OHC) engines dominate modern passenger cars and motorcycles, offering higher RPM capabilities and improved fuel efficiency through precise valve timing control. Your choice between OHV and OHC depends on the specific performance needs and fuel economy priorities of the application.

Pros and Cons of Overhead Valve Engines

Overhead Valve (OHV) engines excel with a compact design and robust low-end torque, making them ideal for trucks and off-road vehicles. Their simpler construction results in easier maintenance and often lower production costs compared to Overhead Cam (OHC) engines. However, OHV engines generally have lower peak power and efficiency, along with limited high-speed performance due to valve train mass and design constraints.

Advantages and Disadvantages of Overhead Camshaft Engines

Overhead camshaft (OHC) engines offer precise valve timing, leading to improved fuel efficiency and higher engine speeds compared to overhead valve (OHV) engines. Their design reduces moving parts, resulting in lower maintenance and enhanced performance, especially in high-revving applications. However, OHC engines tend to be more complex and costly to manufacture, with potential challenges in compact engine packaging and repair difficulty.

Overhead Valve vs Overhead Cam Infographic

libmatt.com

libmatt.com