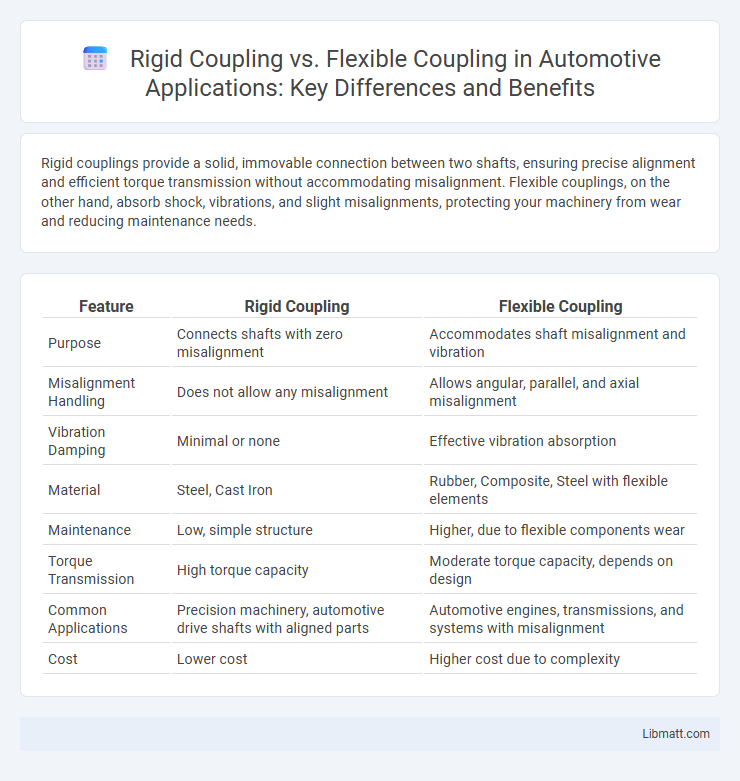

Rigid couplings provide a solid, immovable connection between two shafts, ensuring precise alignment and efficient torque transmission without accommodating misalignment. Flexible couplings, on the other hand, absorb shock, vibrations, and slight misalignments, protecting your machinery from wear and reducing maintenance needs.

Table of Comparison

| Feature | Rigid Coupling | Flexible Coupling |

|---|---|---|

| Purpose | Connects shafts with zero misalignment | Accommodates shaft misalignment and vibration |

| Misalignment Handling | Does not allow any misalignment | Allows angular, parallel, and axial misalignment |

| Vibration Damping | Minimal or none | Effective vibration absorption |

| Material | Steel, Cast Iron | Rubber, Composite, Steel with flexible elements |

| Maintenance | Low, simple structure | Higher, due to flexible components wear |

| Torque Transmission | High torque capacity | Moderate torque capacity, depends on design |

| Common Applications | Precision machinery, automotive drive shafts with aligned parts | Automotive engines, transmissions, and systems with misalignment |

| Cost | Lower cost | Higher cost due to complexity |

Introduction to Shaft Couplings

Shaft couplings connect two rotating shafts to transmit power while accommodating misalignment and torque variations. Rigid couplings provide a solid connection with no allowance for misalignment, making them ideal for precise, stable applications where shafts are perfectly aligned. Flexible couplings absorb shocks and vibrations, allowing for slight misalignments and protecting your machinery from damage.

What is Rigid Coupling?

Rigid coupling is a mechanical device used to connect two shafts together to transmit torque without any relative movement or flexibility between them. It provides precise alignment and allows no misalignment compensation, making it ideal for applications requiring exact shaft positioning. Common materials for rigid couplings include cast iron, steel, and aluminum, chosen for their strength and durability in high-torque environments.

What is Flexible Coupling?

Flexible coupling is a mechanical device designed to transmit torque while accommodating misalignment between connected shafts, reducing stress and wear. It compensates for slight angular, parallel, or axial misalignments, enhancing the longevity and performance of your machinery. Unlike rigid coupling, flexible coupling absorbs vibrations and shocks, protecting components from damage during operation.

Key Differences Between Rigid and Flexible Couplings

Rigid couplings provide a solid, fixed connection between shafts, ensuring no relative movement and precise torque transmission, ideal for applications requiring high alignment accuracy. Flexible couplings accommodate misalignment and absorb shocks or vibrations, enhancing machinery lifespan and reducing wear. Your choice depends on the need for rigidity versus flexibility in shaft connection and operational conditions.

Advantages of Rigid Coupling

Rigid coupling offers precise alignment and high torque transmission, making it ideal for applications requiring minimal shaft misalignment. Its robust design ensures durability and reliability in heavy-duty machinery, reducing maintenance needs and downtime. You benefit from consistent performance in systems where rigidity and exact shaft positioning are critical.

Advantages of Flexible Coupling

Flexible coupling offers superior vibration damping and misalignment tolerance compared to rigid coupling, reducing wear on machinery components and extending equipment lifespan. It accommodates axial, angular, and parallel misalignments, ensuring smoother power transmission and minimizing operational downtime. Your machinery benefits from enhanced shock absorption, leading to lower maintenance costs and increased reliability in dynamic environments.

Typical Applications of Rigid Couplings

Rigid couplings are commonly used in applications requiring precise alignment and high torque transmission, such as in machine tools, servo motors, and robotics. These couplings ensure zero backlash and maintain the exact angular relationship between connected shafts, making them ideal for positioning systems and precision equipment. Industries like automotive, aerospace, and manufacturing often rely on rigid couplings for their superior rigidity and reliability in high-performance environments.

Typical Applications of Flexible Couplings

Flexible couplings are commonly used in applications requiring vibration dampening and misalignment compensation, such as in conveyor systems, pumps, and compressors. They effectively protect sensitive equipment by absorbing shocks and reducing wear caused by angular, parallel, or axial misalignments. Industries like manufacturing, automotive, and robotics frequently deploy flexible couplings to enhance operational reliability and extend machinery lifespan.

Factors to Consider When Choosing a Coupling

Selecting between rigid coupling and flexible coupling depends on several key factors, including misalignment tolerance, torque transmission requirements, and environmental conditions. Rigid couplings are ideal for precise shaft alignment and high torque capacity but lack the ability to absorb shock or accommodate shaft misalignment. Flexible couplings offer greater adaptability by compensating for angular, parallel, and axial misalignments while reducing vibration and noise, which is crucial in applications subject to dynamic loads or slight misalignments.

Conclusion: Which Coupling is Best for Your Application?

Rigid coupling is ideal for applications requiring precise shaft alignment and no relative motion, such as high-torque or minimal backlash systems, ensuring maximum power transmission efficiency. Flexible coupling suits applications with misalignment, vibration absorption, or shock loading, providing durability and protection for connected equipment. Selecting the best coupling depends on factors like alignment accuracy, load conditions, and system rigidity requirements.

Rigid Coupling vs Flexible Coupling Infographic

libmatt.com

libmatt.com