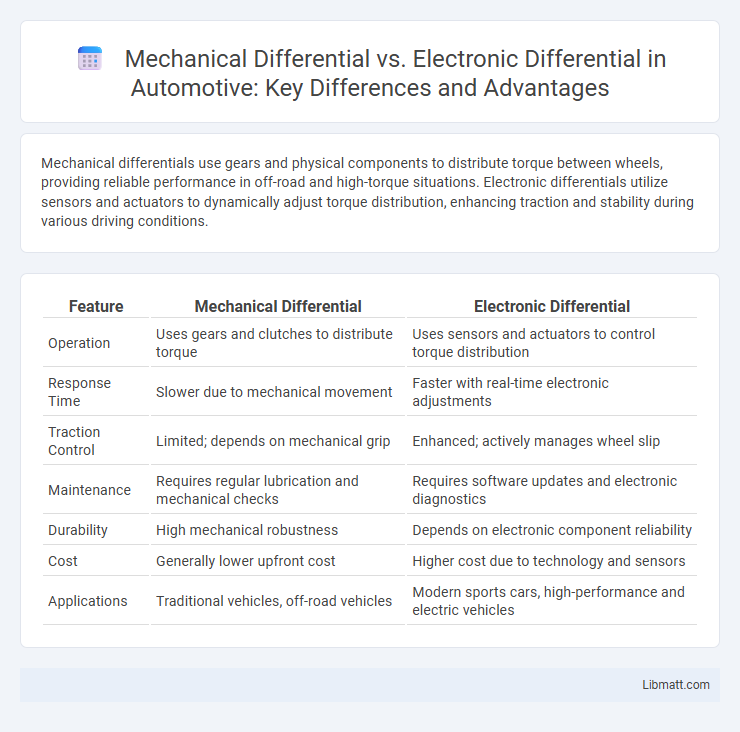

Mechanical differentials use gears and physical components to distribute torque between wheels, providing reliable performance in off-road and high-torque situations. Electronic differentials utilize sensors and actuators to dynamically adjust torque distribution, enhancing traction and stability during various driving conditions.

Table of Comparison

| Feature | Mechanical Differential | Electronic Differential |

|---|---|---|

| Operation | Uses gears and clutches to distribute torque | Uses sensors and actuators to control torque distribution |

| Response Time | Slower due to mechanical movement | Faster with real-time electronic adjustments |

| Traction Control | Limited; depends on mechanical grip | Enhanced; actively manages wheel slip |

| Maintenance | Requires regular lubrication and mechanical checks | Requires software updates and electronic diagnostics |

| Durability | High mechanical robustness | Depends on electronic component reliability |

| Cost | Generally lower upfront cost | Higher cost due to technology and sensors |

| Applications | Traditional vehicles, off-road vehicles | Modern sports cars, high-performance and electric vehicles |

Introduction to Differential Systems

Mechanical differentials use gears to distribute torque between wheels, providing consistent power delivery based on traction conditions. Electronic differentials employ sensors and computer controls to adjust torque dynamically for improved handling and stability in various driving scenarios. Your choice between these systems impacts vehicle performance, especially in cornering and slippery conditions.

What is a Mechanical Differential?

A mechanical differential is a crucial component in vehicles that allows wheels to rotate at different speeds, especially when turning, enhancing traction and handling. It uses gears to distribute torque between the wheels on an axle, adapting to varying road conditions without electronic input. Understanding how your mechanical differential operates can improve your vehicle's performance and maintenance awareness.

What is an Electronic Differential?

An electronic differential uses sensors and control units to independently regulate torque distribution between wheels, enhancing traction and handling more precisely than a traditional mechanical diff. Unlike a mechanical differential that relies on gears and limited-slip mechanisms, an electronic diff adjusts power delivery in real-time based on driving conditions and wheel slip. Your vehicle benefits from improved stability and cornering performance due to the quick response and adaptability of electronic differentials.

Key Components of Mechanical vs Electronic Differentials

Mechanical differentials feature gears such as the spider gears, ring gear, and pinion gear working together to distribute torque between wheels, relying on physical components like shafts and bevel gears for torque transfer. Electronic differentials incorporate sensors, actuators, and electronic control units (ECUs) to manage torque distribution dynamically through software algorithms and electric motors. The key distinction lies in the mechanical differential's purely mechanical gear assembly versus the electronic differential's integration of electronic sensing and control systems for precise torque modulation.

Working Principles: Mechanical Differential Explained

Mechanical differentials work by distributing engine torque to the wheels through a set of gears that allow each wheel to rotate at different speeds, essential for smooth cornering. This system uses spider gears and side gears housed within a differential case, balancing power output between wheels based on traction conditions. Understanding your vehicle's mechanical differential helps optimize handling and performance on varying road surfaces.

Working Principles: Electronic Differential Explained

An electronic differential uses sensors to monitor wheel speed and a microprocessor-controlled actuator to distribute torque precisely between wheels, enhancing traction and handling. Unlike a mechanical differential that relies on gears to balance wheel speed, the electronic differential dynamically adjusts torque by applying brake force or modulating power electronically. This system improves vehicle stability and performance, especially in varying driving conditions where wheel slip occurs.

Performance Comparison: Mechanical vs Electronic Diff

Mechanical differentials deliver consistent torque distribution through gears, providing reliable traction in off-road and high-stress driving conditions. Electronic differentials use sensors and actuators to dynamically adjust torque between wheels, enhancing cornering stability and responsiveness in various driving scenarios. Your choice impacts vehicle handling precision, with electronic diffs offering more adaptive performance and mechanical diffs excelling in durability.

Advantages of Mechanical Differentials

Mechanical differentials provide reliable power distribution between wheels, enhancing traction on uneven surfaces without electronic intervention. Their simplicity ensures durability and lower maintenance costs, making them preferred in off-road and heavy-duty vehicles. Mechanical diffs also function independently of electronic controls, providing consistent performance in extreme conditions where sensors or electronics may fail.

Benefits of Electronic Diferentials

Electronic differentials provide precise torque distribution between wheels, enhancing traction and stability during cornering or slippery conditions. They adapt in real-time to driving dynamics, improving handling performance and safety compared to traditional mechanical differentials. Using an electronic differential can optimize your vehicle's control and responsiveness for a smoother, more efficient driving experience.

Which Differential is Right for Your Vehicle?

Choosing between a mechanical differential and an electronic differential depends on your vehicle's intended use and driving conditions. Mechanical differentials offer durability and simplicity, ideal for off-road or high-stress applications, while electronic differentials provide precise torque control and improved handling, enhancing performance on paved roads. Your decision should consider factors like driving style, terrain, and the need for traction control to determine which differential best suits your vehicle.

Mechanical diff vs Electronic diff Infographic

libmatt.com

libmatt.com