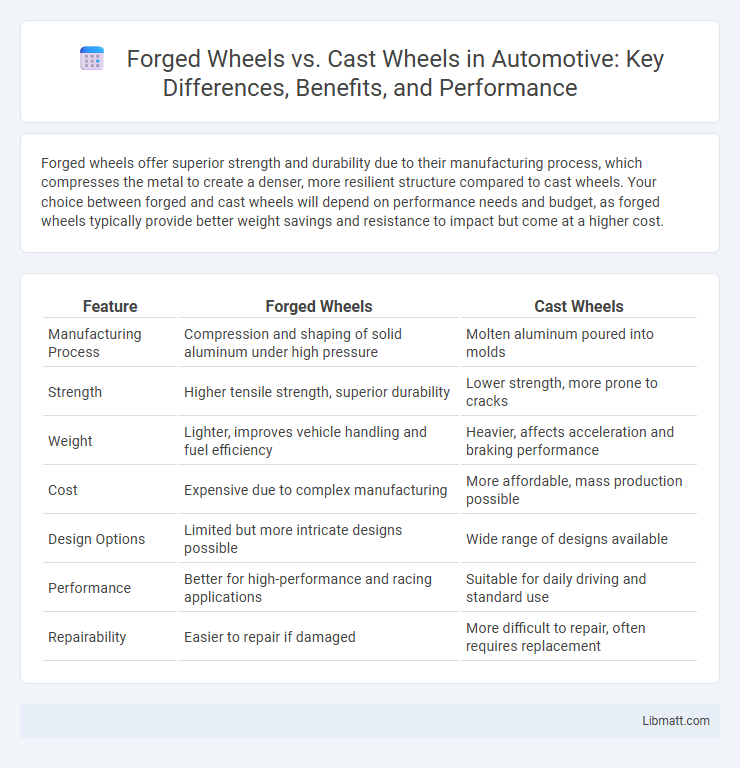

Forged wheels offer superior strength and durability due to their manufacturing process, which compresses the metal to create a denser, more resilient structure compared to cast wheels. Your choice between forged and cast wheels will depend on performance needs and budget, as forged wheels typically provide better weight savings and resistance to impact but come at a higher cost.

Table of Comparison

| Feature | Forged Wheels | Cast Wheels |

|---|---|---|

| Manufacturing Process | Compression and shaping of solid aluminum under high pressure | Molten aluminum poured into molds |

| Strength | Higher tensile strength, superior durability | Lower strength, more prone to cracks |

| Weight | Lighter, improves vehicle handling and fuel efficiency | Heavier, affects acceleration and braking performance |

| Cost | Expensive due to complex manufacturing | More affordable, mass production possible |

| Design Options | Limited but more intricate designs possible | Wide range of designs available |

| Performance | Better for high-performance and racing applications | Suitable for daily driving and standard use |

| Repairability | Easier to repair if damaged | More difficult to repair, often requires replacement |

Introduction to Forged vs Cast Wheels

Forged wheels are manufactured by compressing a solid billet of aluminum under extreme pressure, resulting in a denser and stronger structure compared to cast wheels, which are made by pouring molten aluminum into a mold. This process makes forged wheels lighter and more durable, enhancing vehicle performance and handling. Cast wheels typically have a lower production cost but may lack the rigidity and strength found in forged alternatives.

Manufacturing Processes Explained

Forged wheels are produced by applying extreme pressure to a solid billet of aluminum, resulting in a dense, strong, and lightweight structure. Cast wheels are made by pouring molten aluminum into molds, a process that is more cost-effective but often creates a less dense and heavier wheel. Your choice between forged and cast wheels depends on whether you prioritize strength and performance or budget-friendly options.

Material Differences and Quality

Forged wheels are crafted from a solid billet of high-grade aluminum alloy, offering superior strength and durability due to the compression of metal fibers during the forging process. Cast wheels are produced by pouring molten aluminum into molds, which can result in a lighter and less dense structure, making them more prone to cracks and bends under stress. Your choice between forged and cast wheels should consider forged wheels' enhanced quality and material integrity, ideal for high-performance or heavy-use applications.

Strength and Durability Comparison

Forged wheels exhibit superior strength and durability compared to cast wheels due to their manufacturing process, which involves compressing a solid aluminum billet under high pressure, resulting in a denser and more uniform grain structure. Cast wheels are produced by pouring molten aluminum into molds, making them more prone to cracks and imperfections under stress. The enhanced tensile strength of forged wheels significantly improves resistance to impact and bending, making them ideal for high-performance and off-road applications.

Weight and Performance Impact

Forged wheels are significantly lighter than cast wheels due to their manufacturing process, which results in enhanced weight reduction and improved vehicle performance. Reduced unsprung weight in forged wheels leads to better acceleration, braking, and handling responsiveness, providing a noticeable performance edge. Your vehicle benefits from increased fuel efficiency and superior cornering stability when equipped with forged wheels compared to heavier cast wheels.

Design Flexibility and Aesthetics

Forged wheels offer superior design flexibility due to their manufacturing process, allowing for intricate patterns and lighter, stronger structures that enhance both performance and aesthetics. Cast wheels, formed by pouring molten metal into molds, typically have limitations in design complexity, resulting in heavier and less detailed styles. Your choice between forged and cast wheels significantly impacts the visual appeal and customization options available for your vehicle.

Cost Analysis and Value for Money

Forged wheels generally have a higher upfront cost compared to cast wheels due to their manufacturing process, which involves compressing aluminum alloy under high pressure for superior strength and lighter weight. Cast wheels are more budget-friendly and suitable for everyday driving but may lack the durability and performance benefits that forged wheels offer in high-stress conditions. When considering value for money, forged wheels deliver enhanced longevity, strength, and weight savings that justify their premium price for performance-focused enthusiasts and long-term use.

Common Applications and Usage

Forged wheels are commonly used in high-performance vehicles and motorsports due to their superior strength, lightweight properties, and enhanced durability under extreme conditions. Cast wheels are typically found on everyday passenger cars and trucks, offering affordability and adequate performance for daily driving and moderate road use. Your choice between forged and cast wheels should consider the demands of your driving environment and the level of performance required.

Pros and Cons of Forged Wheels

Forged wheels offer superior strength and durability compared to cast wheels, making them ideal for high-performance vehicles and aggressive driving conditions. Your vehicle benefits from reduced weight, which enhances acceleration, braking, and fuel efficiency; however, forged wheels come at a higher cost and may require more careful maintenance to avoid cosmetic damage. They provide better impact resistance but can be more susceptible to bending under extreme force, whereas cast wheels tend to crack rather than bend.

Pros and Cons of Cast Wheels

Cast wheels offer a cost-effective manufacturing process, making them more affordable than forged wheels while providing a wide range of styles and designs. However, they are generally heavier and less durable, making them more prone to cracks and damage under high stress or impact conditions. Their lower strength-to-weight ratio can affect vehicle performance, particularly in high-performance or racing applications.

forged wheels vs cast wheels Infographic

libmatt.com

libmatt.com