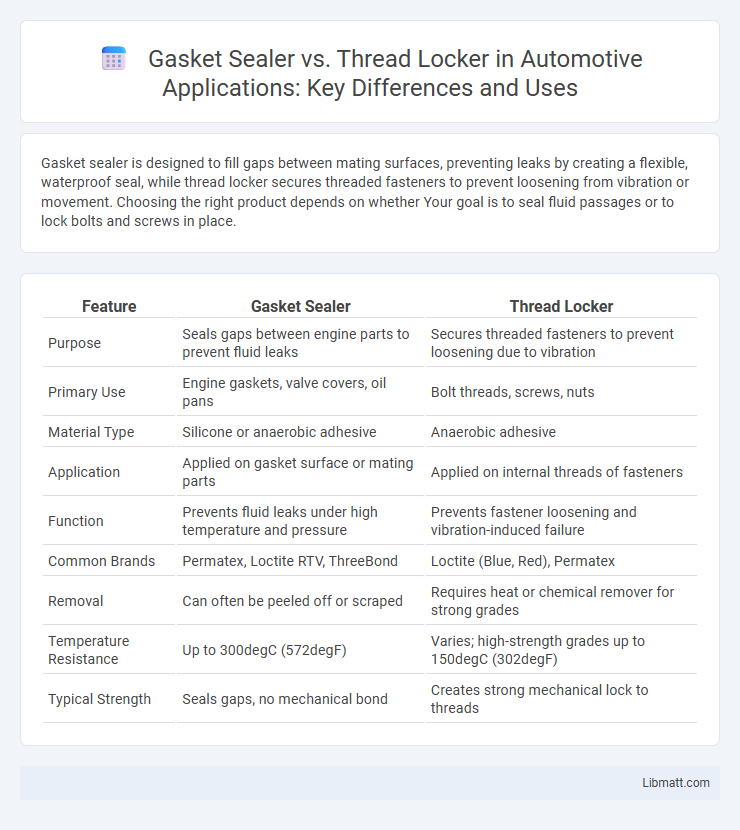

Gasket sealer is designed to fill gaps between mating surfaces, preventing leaks by creating a flexible, waterproof seal, while thread locker secures threaded fasteners to prevent loosening from vibration or movement. Choosing the right product depends on whether Your goal is to seal fluid passages or to lock bolts and screws in place.

Table of Comparison

| Feature | Gasket Sealer | Thread Locker |

|---|---|---|

| Purpose | Seals gaps between engine parts to prevent fluid leaks | Secures threaded fasteners to prevent loosening due to vibration |

| Primary Use | Engine gaskets, valve covers, oil pans | Bolt threads, screws, nuts |

| Material Type | Silicone or anaerobic adhesive | Anaerobic adhesive |

| Application | Applied on gasket surface or mating parts | Applied on internal threads of fasteners |

| Function | Prevents fluid leaks under high temperature and pressure | Prevents fastener loosening and vibration-induced failure |

| Common Brands | Permatex, Loctite RTV, ThreeBond | Loctite (Blue, Red), Permatex |

| Removal | Can often be peeled off or scraped | Requires heat or chemical remover for strong grades |

| Temperature Resistance | Up to 300degC (572degF) | Varies; high-strength grades up to 150degC (302degF) |

| Typical Strength | Seals gaps, no mechanical bond | Creates strong mechanical lock to threads |

Introduction to Gasket Sealers and Thread Lockers

Gasket sealers are specialized compounds designed to fill gaps and create a durable, leak-proof bond between engine or mechanical parts, ensuring tight seals under high pressure and temperature conditions. Thread lockers are adhesive liquids applied to threaded fasteners to prevent loosening, corrosion, and leakage caused by vibration or thermal expansion. Both products enhance mechanical reliability but serve distinct purposes: gasket sealers maintain fluid containment, while thread lockers secure fasteners in place.

What is a Gasket Sealer?

A gasket sealer is a specialized chemical compound designed to enhance the sealing capabilities between engine or mechanical parts by filling surface irregularities and preventing fluid or gas leaks. It acts as an adhesive and coolant-resistant barrier, ensuring a tight seal in applications where gaskets alone may not provide sufficient protection. Ideal for automotive, plumbing, and industrial uses, gasket sealers improve durability and reliability of component joints under high pressure and temperature conditions.

What is a Thread Locker?

A thread locker is a specialized adhesive designed to secure threaded fasteners by preventing loosening caused by vibration or stress. Unlike gasket sealer, which fills gaps and creates a seal between surfaces to prevent fluid leaks, a thread locker penetrates the threads to lock nuts, bolts, or screws in place. Your choice depends on whether you need to maintain a mechanical connection or ensure a fluid-tight seal.

Key Differences: Gasket Sealer vs Thread Locker

Gasket sealer creates a flexible, airtight bond between mating surfaces to prevent fluid leaks, while thread locker secures threaded fasteners by filling gaps and preventing loosening due to vibration. Gasket sealers are designed to maintain gasket integrity under pressure and temperature changes, whereas thread lockers provide mechanical locking properties to fasteners, enhancing joint reliability. Your choice depends on whether the application requires sealing fluid pathways or maintaining bolt tightness.

Common Applications of Gasket Sealers

Gasket sealers are commonly used in automotive engines, industrial machinery, and plumbing systems to create flexible, leak-proof seals between mating surfaces. They are ideal for sealing joints subjected to oil, coolant, fuel, and other fluids, ensuring your engine or equipment operates without fluid leaks. Choosing the right gasket sealer can enhance durability and performance in applications involving metal, rubber, and composite gaskets.

Common Applications of Thread Lockers

Thread lockers are commonly used in automotive, aerospace, and industrial machinery to prevent fasteners from loosening due to vibration and stress. Your equipment benefits from enhanced durability and safety when thread lockers secure bolts, screws, and nuts in critical assemblies. Unlike gasket sealers that prevent fluid leaks, thread lockers specifically ensure mechanical stability and maintain tension in threaded connections.

Pros and Cons of Gasket Sealers

Gasket sealers enhance the sealing capabilities of gaskets by filling gaps and preventing leaks in engine and machinery components, offering strong resistance to oil, coolant, and other fluids. However, they can complicate disassembly, as some sealers cure to a hard finish that may require scraping or solvents for removal. Overuse may cause excess material to flow into unwanted areas, potentially clogging passages or causing mechanical issues.

Pros and Cons of Thread Lockers

Thread lockers provide strong adhesion between threaded fasteners, preventing loosening due to vibration and ensuring long-term stability in mechanical assemblies. They are easy to apply and cure quickly but can be difficult to remove, sometimes requiring heat or special tools, which may complicate future maintenance. Your choice should consider the balance between permanent bonding and the need for disassembly when selecting thread lockers for your projects.

How to Choose the Right Product for Your Project

Choosing between gasket sealer and thread locker depends on your project's specific needs for sealing or fastening. Gasket sealer is ideal for filling gaps and preventing fluid leaks in joints, while thread locker secures fasteners and prevents loosening due to vibration. Assess your application's requirements, such as exposure to fluids or mechanical stress, to ensure your project achieves optimal durability and reliability.

Expert Tips for Effective Sealing and Locking

Gasket sealer creates a flexible, durable barrier preventing fluid leaks in joints, while thread locker secures fasteners by curing to form a strong bond resisting vibration and loosening. Use gasket sealer on uneven or metal-to-metal surfaces requiring a tight seal, and apply thread locker on bolts and screws to maintain assembly integrity under stress. Your choice between the two depends on the specific sealing or locking needs, ensuring optimal performance and safety in mechanical applications.

Gasket sealer vs Thread locker Infographic

libmatt.com

libmatt.com