Leaf springs provide superior load-bearing capacity and durability, making them ideal for heavy-duty vehicles and applications requiring robust suspension systems. Coil springs offer a smoother ride and better handling performance, making them suitable for passenger cars and vehicles focused on comfort.

Table of Comparison

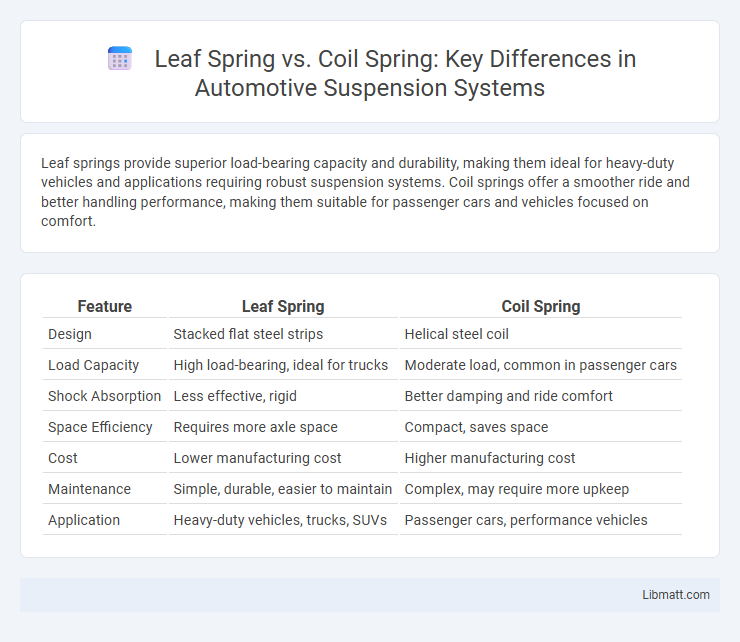

| Feature | Leaf Spring | Coil Spring |

|---|---|---|

| Design | Stacked flat steel strips | Helical steel coil |

| Load Capacity | High load-bearing, ideal for trucks | Moderate load, common in passenger cars |

| Shock Absorption | Less effective, rigid | Better damping and ride comfort |

| Space Efficiency | Requires more axle space | Compact, saves space |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Maintenance | Simple, durable, easier to maintain | Complex, may require more upkeep |

| Application | Heavy-duty vehicles, trucks, SUVs | Passenger cars, performance vehicles |

Introduction to Suspension Systems

Suspension systems rely on either leaf springs or coil springs to absorb shocks and maintain vehicle stability on varied terrains. Leaf springs consist of multiple layers of metal strips that flex under load, offering durability for heavy-duty applications. Coil springs provide a smoother ride through their helical design, making them ideal for passenger cars and performance vehicles.

What Are Leaf Springs?

Leaf springs are a type of suspension system commonly used in trucks and heavy-duty vehicles, consisting of multiple layers of metal strips stacked and curved to absorb shocks. Their design distributes weight evenly across the axle, providing durability and load-bearing capacity ideal for rugged terrains and heavy loads. If your vehicle requires robust support and stability, leaf springs offer a reliable and cost-effective suspension solution.

What Are Coil Springs?

Coil springs are helical-shaped metal springs designed to absorb shock and maintain vehicle suspension height by compressing and expanding under load. Commonly made from high-grade steel, coil springs provide a smoother ride and better handling compared to leaf springs due to their flexibility and ability to better distribute weight. They are widely used in modern passenger cars, motorcycles, and light trucks for improved suspension performance and comfort.

Key Differences Between Leaf and Coil Springs

Leaf springs consist of multiple layers of metal strips stacked together, providing robust support for heavy loads and commonly used in trucks and commercial vehicles, while coil springs are made of a single steel wire wound into a helix, offering greater flexibility and smoother ride quality typical in passenger cars. Leaf springs deliver superior load distribution and durability for off-road and heavy-duty applications, whereas coil springs excel in ride comfort and handling precision on paved roads. Your vehicle's suspension performance and load requirements determine the optimal choice between leaf and coil springs.

Performance Comparison: Leaf vs Coil Springs

Leaf springs provide robust load-bearing capacity and durability, ideal for heavy-duty vehicles and off-road applications, while coil springs offer superior ride comfort and flexibility, enhancing handling and shock absorption in passenger cars. Coil springs deliver better responsiveness and smoother performance over uneven terrain, whereas leaf springs excel in maintaining stability under heavy loads and minimizing axle wrap. Understanding your vehicle's intended use helps determine whether leaf springs or coil springs best optimize performance for strength or comfort.

Applications in Vehicles

Leaf springs are commonly used in heavy-duty vehicles such as trucks and SUVs due to their capacity to support substantial loads and provide stability on uneven terrain. Coil springs, favored in passenger cars and performance vehicles, offer superior ride comfort and handling by absorbing shocks more efficiently. Your choice between the two impacts vehicle load capacity, ride quality, and overall suspension performance.

Pros and Cons of Leaf Springs

Leaf springs offer high load-carrying capacity and durability, making them ideal for heavy-duty vehicles such as trucks and SUVs. They provide a simple and cost-effective suspension design but tend to deliver a rougher ride compared to coil springs due to less flexibility and damping. However, their weight and space requirements can limit vehicle handling and design options.

Pros and Cons of Coil Springs

Coil springs offer excellent ride comfort and better handling due to their ability to compress and expand smoothly, making them ideal for passenger cars and performance vehicles. They are lightweight, compact, and provide consistent ride height, but they can be more expensive to manufacture and less durable under heavy load conditions compared to leaf springs. Maintenance is generally lower, though coil springs may require additional components like shock absorbers to control rebound and prevent excessive bouncing.

Maintenance and Durability

Leaf springs require less frequent maintenance due to their simple, robust design but are prone to sagging and corrosion over time, affecting durability. Coil springs, while needing occasional inspection for cracks or deformation, typically offer better resistance to deformation and longer lifespan, especially in vehicles requiring smoother rides. Your choice should consider the driving conditions and maintenance capabilities to optimize suspension performance and durability.

Choosing the Right Spring for Your Vehicle

Choosing the right spring for your vehicle depends on factors like load capacity, ride comfort, and terrain. Leaf springs offer superior load-bearing capabilities and durability, making them ideal for trucks and heavy-duty vehicles. Coil springs deliver better ride quality and handling, suited for passenger cars and light-duty trucks.

Leaf spring vs Coil spring Infographic

libmatt.com

libmatt.com