Mass air flow (MAF) sensors measure the actual amount of air entering the engine, providing precise data for optimal fuel delivery and combustion efficiency. Speed density systems estimate air mass using engine speed and manifold pressure, relying on calculations rather than direct measurement, which can lead to less accurate fueling under varying conditions.

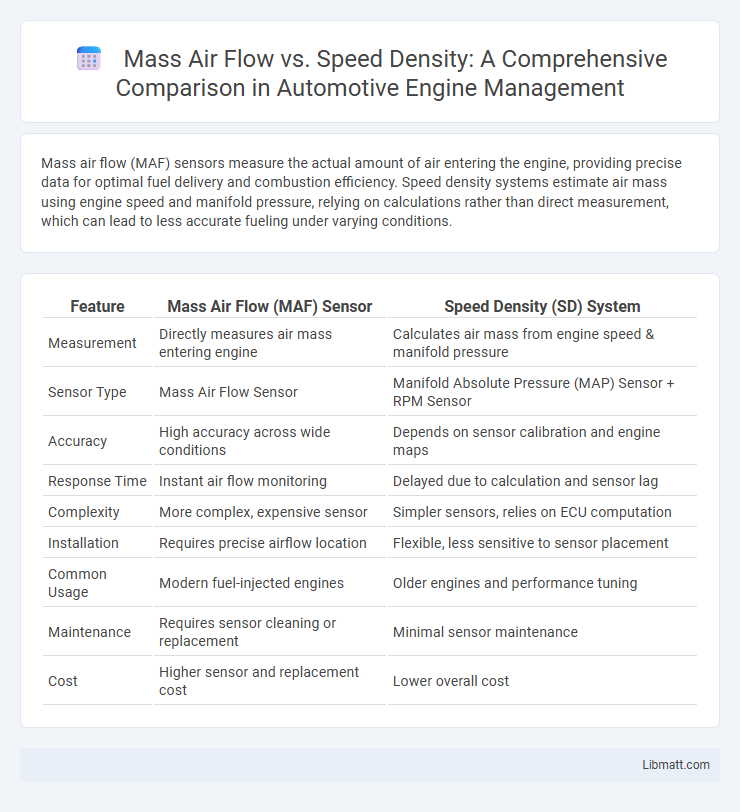

Table of Comparison

| Feature | Mass Air Flow (MAF) Sensor | Speed Density (SD) System |

|---|---|---|

| Measurement | Directly measures air mass entering engine | Calculates air mass from engine speed & manifold pressure |

| Sensor Type | Mass Air Flow Sensor | Manifold Absolute Pressure (MAP) Sensor + RPM Sensor |

| Accuracy | High accuracy across wide conditions | Depends on sensor calibration and engine maps |

| Response Time | Instant air flow monitoring | Delayed due to calculation and sensor lag |

| Complexity | More complex, expensive sensor | Simpler sensors, relies on ECU computation |

| Installation | Requires precise airflow location | Flexible, less sensitive to sensor placement |

| Common Usage | Modern fuel-injected engines | Older engines and performance tuning |

| Maintenance | Requires sensor cleaning or replacement | Minimal sensor maintenance |

| Cost | Higher sensor and replacement cost | Lower overall cost |

Introduction to Mass Air Flow and Speed Density

Mass Air Flow (MAF) and Speed Density are two primary methods for calculating engine air intake to optimize fuel delivery and combustion efficiency. MAF sensors directly measure the volume of incoming air, providing real-time data to the ECU, while Speed Density relies on engine speed and manifold pressure using pre-programmed maps to estimate airflow. Understanding these systems helps you choose the best approach for accurate fuel injection and enhanced engine performance.

Understanding Mass Air Flow (MAF) Systems

Mass Air Flow (MAF) systems measure the exact amount of air entering an engine by using a sensor located between the air filter and intake manifold, providing real-time data for precise fuel injection control. Unlike speed density systems that rely on manifold pressure and engine speed sensors to estimate airflow, MAF systems deliver more accurate measurements, improving engine efficiency and emissions control. This technology is crucial for modern engines to optimize combustion and maintain optimal performance under varying operating conditions.

Overview of Speed Density Systems

Speed density systems estimate engine airflow by using manifold absolute pressure (MAP), intake air temperature (IAT), and engine speed (RPM) to calculate air mass instead of directly measuring it. These systems rely on pre-calibrated volumetric efficiency and air-fuel ratio maps to determine the necessary fuel delivery, allowing for simpler hardware with no need for a mass air flow (MAF) sensor. Speed density tuning is often preferred in performance applications due to its faster response time and improved accuracy under transient conditions compared to MAF-based methods.

Key Differences Between MAF and Speed Density

Mass Air Flow (MAF) sensors measure the actual amount of air entering the engine, providing precise real-time data to optimize fuel injection and combustion. In contrast, Speed Density systems calculate airflow based on engine speed, manifold pressure, and temperature, relying on predictive algorithms rather than direct measurement. Your choice between MAF and Speed Density impacts engine performance, tuning flexibility, and response to modifications.

Performance Comparison: MAF vs Speed Density

Mass Air Flow (MAF) sensors provide precise real-time measurement of the actual air entering the engine, resulting in more accurate fuel delivery and improved overall performance. Speed Density systems rely on pre-calibrated engine parameters and manifold pressure to estimate airflow, which can lead to less accuracy under varying conditions but allow for faster response and simpler design. Your choice between MAF and Speed Density impacts engine tuning precision and responsiveness, with MAF favored for performance consistency and Speed Density preferred in customized or forced induction setups.

Tuning and Calibration Considerations

Mass air flow (MAF) sensors provide direct measurement of the air entering the engine, enabling precise fuel delivery tuning, while speed density systems rely on manifold absolute pressure (MAP) and engine speed for fuel calculation, requiring careful calibration of volumetric efficiency and air temperature parameters. Tuning with MAF systems often simplifies real-time adjustments, whereas speed density tuning demands thorough understanding of engine airflow characteristics to achieve optimal performance. Your calibration strategy should consider sensor accuracy, response time, and environmental variations to ensure consistent engine operation.

Pros and Cons of Mass Air Flow Systems

Mass Air Flow (MAF) systems provide accurate real-time measurement of the volume and density of incoming air, allowing for precise fuel delivery that enhances engine performance and fuel efficiency. Your engine can adapt better to varying conditions with MAF sensors, but these systems are often more expensive and susceptible to contamination or sensor failure, which can lead to inaccurate readings. While MAF systems simplify tuning and diagnostics, they may require more maintenance and replacement compared to Speed Density systems that rely on manifold pressure and RPM data.

Advantages and Drawbacks of Speed Density

Speed density systems offer precise control over air-fuel mixture by relying on manifold pressure and engine RPM data, reducing dependency on a physical mass air flow (MAF) sensor and allowing better performance in modified engines. However, speed density requires accurate tuning and calibration to avoid errors in airflow estimation, which can lead to drivability issues or increased emissions. You may find speed density advantageous for custom or high-performance applications though it demands expertise to maintain optimal engine operation.

Application Scenarios: Which System Suits Your Engine?

Mass air flow (MAF) sensors excel in applications requiring real-time, precise measurement of incoming air, making them ideal for modern fuel-injected engines that demand accurate air-fuel ratio control under varying conditions. Speed density systems rely on intake manifold pressure and engine speed data, commonly used in older or simpler engines where cost efficiency and robustness are prioritized over absolute measurement accuracy. Your choice between MAF and speed density depends on engine complexity, tuning flexibility, and the level of performance optimization required for your specific vehicle setup.

Conclusion: Choosing Between MAF and Speed Density

Choosing between Mass Air Flow (MAF) and Speed Density systems depends on your vehicle's performance needs and tuning preferences. MAF sensors provide real-time, precise airflow measurements ideal for stock or mildly modified engines, while Speed Density systems offer flexibility and faster response in high-performance or heavily modified setups by calculating air mass based on manifold pressure and engine speed. Your optimal choice balances accuracy, complexity, and adaptability to ensure efficient engine management and optimal power output.

mass air flow vs speed density Infographic

libmatt.com

libmatt.com