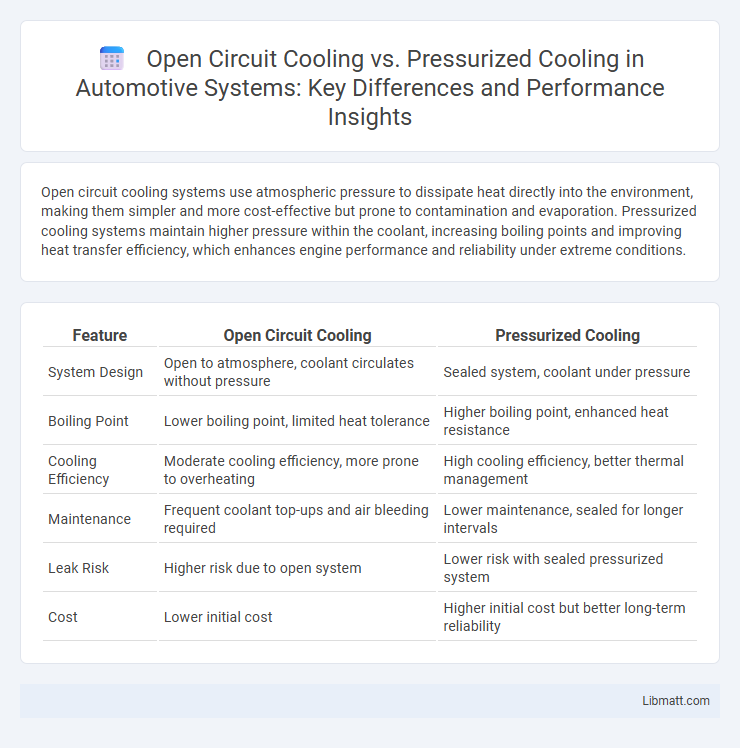

Open circuit cooling systems use atmospheric pressure to dissipate heat directly into the environment, making them simpler and more cost-effective but prone to contamination and evaporation. Pressurized cooling systems maintain higher pressure within the coolant, increasing boiling points and improving heat transfer efficiency, which enhances engine performance and reliability under extreme conditions.

Table of Comparison

| Feature | Open Circuit Cooling | Pressurized Cooling |

|---|---|---|

| System Design | Open to atmosphere, coolant circulates without pressure | Sealed system, coolant under pressure |

| Boiling Point | Lower boiling point, limited heat tolerance | Higher boiling point, enhanced heat resistance |

| Cooling Efficiency | Moderate cooling efficiency, more prone to overheating | High cooling efficiency, better thermal management |

| Maintenance | Frequent coolant top-ups and air bleeding required | Lower maintenance, sealed for longer intervals |

| Leak Risk | Higher risk due to open system | Lower risk with sealed pressurized system |

| Cost | Lower initial cost | Higher initial cost but better long-term reliability |

Introduction to Engine Cooling Systems

Engine cooling systems are essential for maintaining optimal operating temperatures and preventing overheating in internal combustion engines. Open circuit cooling uses ambient air or a cooling fluid that is exposed to the atmosphere, allowing heat to dissipate naturally but often resulting in lower thermal efficiency. Pressurized cooling systems increase the coolant's boiling point by maintaining higher pressure, enhancing heat transfer efficiency and improving engine performance and longevity.

What is Open Circuit Cooling?

Open Circuit Cooling is a system where coolant circulates through the engine and is then exposed to the atmosphere in a reservoir or radiator, allowing heat to dissipate before the fluid returns to the engine. This design is common in many automotive and industrial engines because it is simpler and easier to maintain. Your choice of Open Circuit Cooling affects efficiency, especially in environments where external contamination or coolant evaporation needs to be considered.

What is Pressurized Cooling?

Pressurized cooling is a thermal management system that uses sealed, pressurized fluid to absorb and dissipate heat more efficiently than open circuit cooling. By maintaining higher pressure, the coolant's boiling point is elevated, allowing your engine or machinery to operate at higher temperatures without overheating. This method ensures improved heat transfer, reduced coolant loss, and enhanced durability in high-performance or heavy-duty applications.

Key Components of Open vs Pressurized Systems

Open circuit cooling systems feature key components such as an open reservoir, radiator, water pump, and thermostat that allow coolant to flow directly exposed to atmospheric pressure. Pressurized cooling systems include a sealed reservoir, pressure cap, radiator, thermostat, and water pump, designed to maintain higher pressure, raising coolant boiling points and improving heat dissipation. Your choice between these systems impacts cooling efficiency, engine temperature regulation, and potential coolant loss.

How Open Circuit Cooling Works

Open Circuit Cooling operates by directly exposing the coolant to the atmosphere after it absorbs heat from the engine, allowing the heat to dissipate naturally. This system utilizes a simple radiator and water pump to circulate coolant through the engine block where heat exchange occurs. The exposed coolant is replaced regularly to maintain effective temperature control, making it less complex but more prone to contamination and evaporation compared to Pressurized Cooling systems.

How Pressurized Cooling Operates

Pressurized cooling operates by maintaining a sealed system where coolant is circulated under increased pressure, raising its boiling point and enhancing heat transfer efficiency. This method prevents vapor formation and allows higher engine temperatures without overheating, improving performance and reliability. Your engine benefits from consistent thermal management, reducing the risk of coolant loss and system failures common in open circuit cooling.

Advantages of Open Circuit Cooling

Open Circuit Cooling offers distinct advantages such as simplicity in design, reduced maintenance costs, and effective heat dissipation through direct exposure to ambient air. This method allows efficient cooling without the need for complex pressure vessels, making it ideal for environments where ease of access and system reliability are critical. Your equipment benefits from lower operational risks and extended service life due to the straightforward, open-air cooling process.

Benefits of Pressurized Cooling Systems

Pressurized cooling systems enhance engine efficiency by maintaining consistent coolant flow under higher pressure, which raises the boiling point of the coolant and reduces the risk of overheating. These systems minimize coolant loss and improve heat transfer, leading to better temperature regulation and extended engine life. Increased pressure also supports more compact radiator designs, optimizing space within the engine compartment.

Performance Comparison: Open vs Pressurized Cooling

Open circuit cooling systems typically offer lower thermal efficiency due to exposure to ambient air and potential contamination, limiting their performance in high-heat applications. Pressurized cooling systems maintain higher coolant pressure, raising boiling points and improving heat transfer rates, which enhances overall engine performance and durability. Performance metrics such as coolant temperature stability, heat dissipation capacity, and engine operating temperature range consistently favor pressurized cooling in demanding environments.

Choosing the Right Cooling System for Your Needs

Choosing the right cooling system for your needs involves understanding the differences between open circuit cooling and pressurized cooling. Open circuit cooling relies on ambient air or water to dissipate heat, making it simpler and cost-effective for smaller or less demanding applications. Pressurized cooling systems, meanwhile, provide more efficient heat transfer by maintaining higher coolant pressure, ideal for high-performance engines or environments requiring consistent temperature control.

Open Circuit Cooling vs Pressurized Cooling Infographic

libmatt.com

libmatt.com