A map sensor measures the pressure inside the intake manifold to determine the engine load, while a MAF sensor directly measures the amount of air entering the engine. Understanding the difference helps you optimize engine performance and fuel efficiency by ensuring accurate air-fuel mixture calculations.

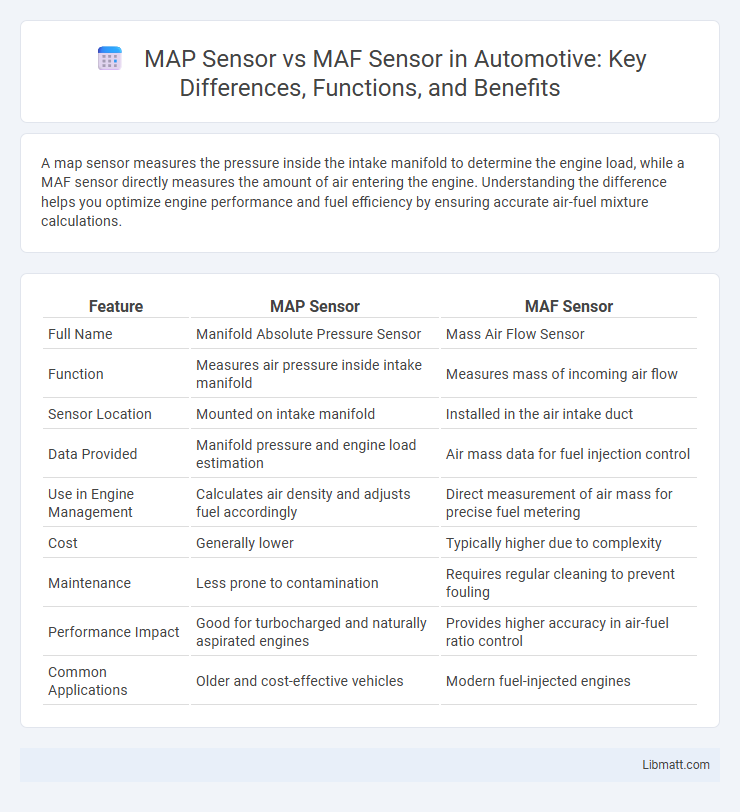

Table of Comparison

| Feature | MAP Sensor | MAF Sensor |

|---|---|---|

| Full Name | Manifold Absolute Pressure Sensor | Mass Air Flow Sensor |

| Function | Measures air pressure inside intake manifold | Measures mass of incoming air flow |

| Sensor Location | Mounted on intake manifold | Installed in the air intake duct |

| Data Provided | Manifold pressure and engine load estimation | Air mass data for fuel injection control |

| Use in Engine Management | Calculates air density and adjusts fuel accordingly | Direct measurement of air mass for precise fuel metering |

| Cost | Generally lower | Typically higher due to complexity |

| Maintenance | Less prone to contamination | Requires regular cleaning to prevent fouling |

| Performance Impact | Good for turbocharged and naturally aspirated engines | Provides higher accuracy in air-fuel ratio control |

| Common Applications | Older and cost-effective vehicles | Modern fuel-injected engines |

Introduction to MAP and MAF Sensors

MAP (Manifold Absolute Pressure) sensors measure the absolute pressure within the intake manifold, providing critical data for calculating air density and engine load. MAF (Mass Air Flow) sensors directly measure the mass of incoming air to the engine intake, enabling precise fuel injection control for optimal combustion. Both sensors are integral to modern engine management systems, but MAP sensors infer airflow indirectly via pressure, while MAF sensors provide a direct airflow measurement.

What is a MAP Sensor?

A MAP sensor (Manifold Absolute Pressure sensor) measures the pressure inside the intake manifold, providing real-time data to the engine control unit (ECU) for accurate air-fuel mixture adjustments. Unlike the MAF sensor that measures the volume of incoming air, the MAP sensor detects air pressure changes, which helps optimize engine performance and fuel efficiency. The sensor is crucial in turbocharged and naturally aspirated engines for monitoring engine load and ensuring proper combustion.

What is a MAF Sensor?

A Mass Air Flow (MAF) sensor measures the exact amount of air entering the engine to optimize fuel injection and improve combustion efficiency. Unlike a MAP sensor that estimates air pressure in the intake manifold, a MAF sensor provides direct airflow data, enhancing engine performance and fuel economy. Understanding your MAF sensor's role ensures accurate air-fuel mixture and smoother vehicle operation.

How MAP Sensors Work

MAP sensors measure the absolute pressure inside the intake manifold to determine engine load by sending voltage signals to the engine control unit (ECU). Your ECU uses this data to calculate the correct air-fuel mixture for optimal combustion and fuel efficiency. Unlike MAF sensors that measure airflow directly, MAP sensors infer air quantity from pressure changes, making them essential for turbocharged or variable intake systems.

How MAF Sensors Work

MAF sensors measure the mass of air entering the engine by detecting changes in a heated wire's temperature, which fluctuates based on airflow. This precise measurement helps the engine control unit (ECU) adjust fuel injection for optimal combustion and efficiency. You benefit from improved fuel economy and reduced emissions due to the MAF sensor's accurate air intake readings.

Key Differences Between MAP and MAF Sensors

MAP (Manifold Absolute Pressure) and MAF (Mass Air Flow) sensors both measure air intake for engine management but operate using different principles; MAP sensors monitor air pressure in the intake manifold to estimate air density, while MAF sensors directly measure the volume and density of incoming air. MAP sensors are typically more cost-effective and better suited for turbocharged engines where pressure changes are significant, whereas MAF sensors provide more precise airflow data for naturally aspirated engines, improving fuel efficiency and emissions control. Understanding the key distinction--pressure measurement versus direct airflow measurement--helps optimize sensor selection for specific engine types and performance requirements.

MAP Sensor Advantages and Disadvantages

A MAP sensor offers advantages such as a simpler design, lower cost, and better accuracy in measuring engine load under certain conditions, which enhances fuel efficiency and performance in turbocharged and supercharged engines. However, MAP sensors can be less effective in naturally aspirated engines due to sensitivity to intake air temperature and pressure changes, leading to potential inaccuracies in fuel delivery. Maintenance is relatively low, but sensor failure or contamination can cause poor engine performance, making periodic checks important.

MAF Sensor Advantages and Disadvantages

MAF sensors measure the actual amount of air entering the engine, providing precise data for optimal fuel injection, resulting in better fuel efficiency and smoother engine performance. However, MAF sensors can be more expensive and sensitive to contamination, requiring regular maintenance to avoid inaccurate readings. Your vehicle benefits from accurate airflow measurement with a MAF sensor, but it may face challenges due to environmental factors or sensor fouling.

Applications: When to Use MAP vs MAF Sensors

MAP sensors are best used in forced induction engines and environments with variable air pressure, providing accurate manifold pressure data for precise fuel delivery. MAF sensors excel in naturally aspirated engines by directly measuring airflow, which helps optimize fuel injection and improve fuel efficiency. Your choice depends on engine type and desired data accuracy for performance tuning or emissions control.

Choosing the Right Sensor for Your Vehicle

Choosing the right sensor for your vehicle depends on its engine type and performance needs; MAP sensors measure intake manifold pressure and are ideal for turbocharged or high-performance engines requiring precise boost control. MAF sensors measure the mass of incoming air and are commonly used in naturally aspirated engines for accurate fuel injection and optimal air-fuel mixture. Understanding your vehicle's specifications ensures you select the most efficient sensor, improving engine efficiency and overall performance.

map sensor vs maf sensor Infographic

libmatt.com

libmatt.com