P-clamps offer secure and organized cable management with a built-in rubber lining that protects wires from abrasion, making them ideal for automotive and industrial applications. Adel clamps, also known as cushioned or insulation clamps, provide superior vibration damping and insulation for your cables, ensuring enhanced durability in electrical installations.

Table of Comparison

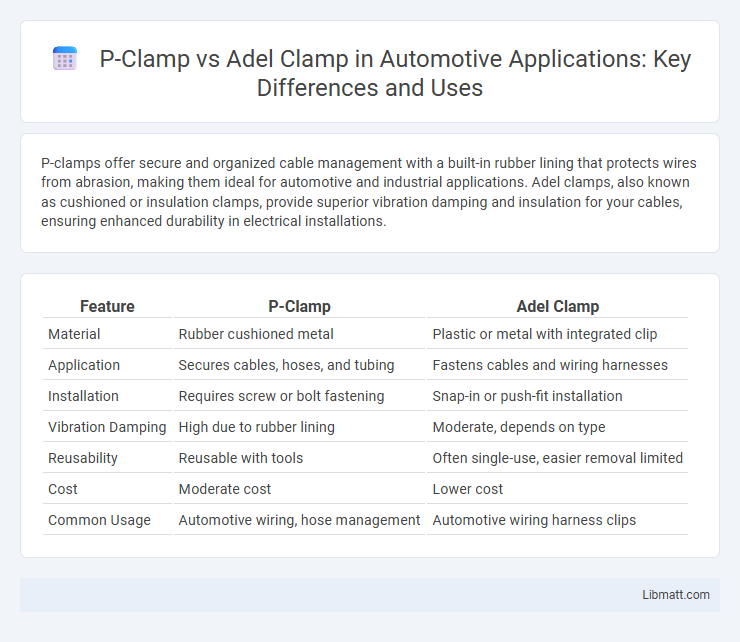

| Feature | P-Clamp | Adel Clamp |

|---|---|---|

| Material | Rubber cushioned metal | Plastic or metal with integrated clip |

| Application | Secures cables, hoses, and tubing | Fastens cables and wiring harnesses |

| Installation | Requires screw or bolt fastening | Snap-in or push-fit installation |

| Vibration Damping | High due to rubber lining | Moderate, depends on type |

| Reusability | Reusable with tools | Often single-use, easier removal limited |

| Cost | Moderate cost | Lower cost |

| Common Usage | Automotive wiring, hose management | Automotive wiring harness clips |

Introduction to P-Clamp and Adel Clamp

P-Clamps and Adel Clamps serve as essential fastening solutions in cable management and mounting applications. P-Clamps, typically made from metal or plastic, feature a looped design for secure attachment of cables, hoses, or pipes to surfaces without slipping. Adel Clamps, also known as wire rope clips, consist of a U-bolt, a saddle, and nuts, primarily used for clamping wire ropes or cables, ensuring tight and stable connections in rigging or lifting operations.

Overview of Hose Clamp Technologies

Hose clamp technologies such as P-clamps and Adel clamps serve distinct purposes in securing hoses and cables in various industries. P-clamps, typically made of metal with a cushioned lining, provide firm support and vibration resistance, making them ideal for automotive and aerospace applications. Adel clamps, featuring a plastic or metal strap with a captured lock, offer easy installation and adjustment, commonly used in plumbing and electrical systems to organize and secure hoses efficiently.

P-Clamp: Design and Key Features

P-Clamps feature a sturdy, U-shaped metal band with an insulated lining, providing secure cable management and vibration dampening. Designed for easy installation, these clamps offer a low-profile solution ideal for holding wires, hoses, and tubes in automotive, aerospace, and industrial applications. Their durable construction ensures long-lasting support, protecting your cables from abrasion and environmental damage.

Adel Clamp: Structure and Unique Attributes

Adel Clamp features a robust metal construction designed for secure cable management in heavy-duty applications, providing superior grip and durability compared to plastic alternatives. Its unique attributes include a hinged design with integrated locking tabs that ensure quick installation and reliable fastening under vibration or movement. You benefit from enhanced stability and longevity, especially in industrial or automotive environments where consistent performance is critical.

Material Differences between P-Clamp and Adel Clamp

P-Clamps are typically made from stainless steel or cushioned with rubber lining to provide corrosion resistance and reduce vibration, making them ideal for securing cables and tubing in harsh environments. Adel clamps, often composed of galvanized steel, offer robust mechanical strength and cost-effectiveness but may require additional treatment for corrosion resistance in outdoor applications. The choice between P-Clamp and Adel clamp materials depends on factors like environmental exposure, mechanical stress, and the necessity for insulation to protect sensitive wiring.

Common Applications for P-Clamps

P-clamps are commonly used in automotive, aerospace, and electrical industries for securing cables, hoses, and tubing due to their durable metal or plastic construction and strong clamping force. They provide reliable strain relief and organization in wiring harnesses, fuel lines, and hydraulic hoses, enhancing safety and operational efficiency. Compared to Adel clamps, P-clamps offer superior resistance to vibration and corrosion, making them ideal for harsh environments.

Typical Uses of Adel Clamps

Adel clamps are typically used in industrial and electrical applications to secure cables, pipes, and hoses to surfaces without causing damage or requiring permanent modifications. Their robust design and insulated lining make them ideal for environments where vibration and wear resistance are critical, such as automotive, aerospace, and heavy machinery sectors. Unlike p-clamps, Adel clamps provide enhanced grip and protection, especially suitable for managing larger cable bundles and ensuring long-term durability in harsh conditions.

Installation Process: P-Clamp vs Adel Clamp

The installation process of a P-Clamp involves securing the clamp by tightening a screw or bolt around cables or pipes, offering a straightforward and firm grip ideal for consistent cable runs. Adel Clamps require the insertion of cables into the clamp body followed by mounting the unit typically with bolts or screws, providing a quick-release feature ideal for maintenance and adjustments. Both clamps offer reliability; however, P-Clamps excel in applications needing robust, permanent fastening, while Adel Clamps are preferred for ease of installation and flexible access.

Pros and Cons: P-Clamp Compared to Adel Clamp

P-clamps offer a secure grip on cables and hoses with a corrosion-resistant design, ideal for heavy-duty applications but may cause insulation damage if over-tightened. Adel clamps provide a lightweight, flexible solution with easy installation and vibration resistance, yet they may lack the strength needed for larger conduits. Choosing between P-clamps and Adel clamps depends on the specific requirements of durability, cable protection, and environmental conditions.

Choosing the Right Clamp for Your Project

Selecting the right clamp depends on your project's specific requirements, where p-clamps offer durable, corrosion-resistant support ideal for securing cables and hoses in automotive and industrial applications. Adel clamps provide versatile, heavy-duty performance with superior grip and shock absorption, making them suitable for construction and heavy machinery. Prioritize material compatibility, load capacity, and environmental conditions to ensure optimal clamp selection for long-lasting performance.

p-clamp vs adel clamp Infographic

libmatt.com

libmatt.com