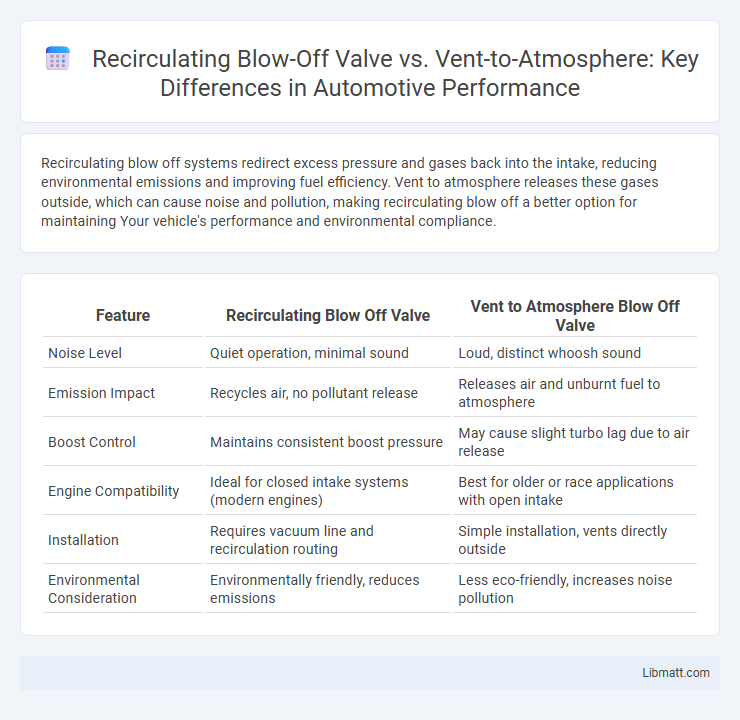

Recirculating blow off systems redirect excess pressure and gases back into the intake, reducing environmental emissions and improving fuel efficiency. Vent to atmosphere releases these gases outside, which can cause noise and pollution, making recirculating blow off a better option for maintaining Your vehicle's performance and environmental compliance.

Table of Comparison

| Feature | Recirculating Blow Off Valve | Vent to Atmosphere Blow Off Valve |

|---|---|---|

| Noise Level | Quiet operation, minimal sound | Loud, distinct whoosh sound |

| Emission Impact | Recycles air, no pollutant release | Releases air and unburnt fuel to atmosphere |

| Boost Control | Maintains consistent boost pressure | May cause slight turbo lag due to air release |

| Engine Compatibility | Ideal for closed intake systems (modern engines) | Best for older or race applications with open intake |

| Installation | Requires vacuum line and recirculation routing | Simple installation, vents directly outside |

| Environmental Consideration | Environmentally friendly, reduces emissions | Less eco-friendly, increases noise pollution |

Introduction to Blow Off Valve Systems

Blow off valve (BOV) systems regulate excess pressure in turbocharged engines by redirecting compressed air to prevent compressor surge and protect the turbocharger. Recirculating blow off valves route this excess air back into the intake system, maintaining closed-loop airflow and reducing noise, which benefits vehicles with mass airflow sensors. Vent to atmosphere blow off valves release the excess pressure directly outside the engine bay, producing a distinct hissing sound but can cause issues with air-fuel mixture sensors and emissions compliance.

What is a Recirculating Blow Off Valve?

A Recirculating Blow Off Valve (BOV) is a device used in turbocharged engines to release excess boost pressure back into the intake system instead of venting it to the atmosphere. This prevents compressor surge, protects the turbocharger, and reduces noise pollution by recapturing the pressurized air. Recirculating BOVs improve engine longevity and maintain smoother throttle response compared to vent-to-atmosphere valves.

What is a Vent to Atmosphere Blow Off Valve?

A Vent to Atmosphere Blow Off Valve releases excess pressure or fluid directly into the atmosphere, preventing system overpressure. This valve is commonly used in applications where venting to open air poses no safety or environmental concerns. In contrast, recirculating blow off valves redirect the discharged material back into the system, minimizing emissions and conserving resources.

Key Differences: Recirculating vs Vent to Atmosphere

Recirculating blow off systems reroute steam or condensate back into the process, enhancing energy efficiency and reducing emissions compared to vent-to-atmosphere methods which release steam directly into the environment. You benefit from lower operational costs and improved environmental compliance with recirculating systems due to reduced energy waste and minimized heat loss. Vent-to-atmosphere systems are simpler but lead to higher energy consumption and increased environmental impact by expelling valuable steam.

Performance Impact on Turbocharged Engines

Recirculating blow off valves (BOVs) maintain turbocharger spool pressure by redirecting excess boost back into the intake system, enhancing throttle response and reducing turbo lag in turbocharged engines. Venting to the atmosphere can cause a temporary drop in manifold pressure, leading to slower turbo spool-up and potential air-fuel ratio imbalances that may affect performance and engine longevity. Choosing recirculation helps preserve air mass flow consistency, promoting smoother acceleration and improved fuel efficiency under varying load conditions.

Effects on Fuel Efficiency and Emissions

Recirculating blow off gases improves fuel efficiency by reducing air-fuel mixture losses and maintaining turbocharger pressure, which enhances combustion stability. This method lowers emissions of unburned hydrocarbons and particulate matter by preventing waste of pressurized air and fuel. Venting to atmosphere causes energy loss and increased pollutant release due to the direct discharge of pressurized gases, negatively impacting overall engine performance and environmental compliance.

Noise Levels and Sound Preferences

Recirculating blow off systems significantly reduce noise levels by capturing and redirecting compressed air within a closed loop, preventing loud exhaust sounds typical in vent-to-atmosphere setups. Venting to atmosphere releases compressed air directly into the environment, generating high decibel noise that can disrupt workspaces and require additional soundproofing measures. Noise reduction with recirculating systems enhances worker comfort and safety, aligning with industrial sound regulations and preferred sound level standards.

Installation Considerations and Compatibility

Recirculating blow off systems require sealed enclosures and condensate recovery equipment to manage expelled gases, making installation more complex compared to vent-to-atmosphere setups that only need open piping. Compatibility with existing infrastructure is critical; recirculating systems demand corrosion-resistant materials and proper sealing to prevent leaks, while vent-to-atmosphere configurations must comply with environmental regulations regarding emissions. Equipment space and access for maintenance are also key factors, as recirculating installations often need additional components like scrubbers or filters.

Pros and Cons of Each Blow Off Setup

Recirculating blow off systems capture and reuse discharged fluids, reducing environmental impact and operational costs, but require more complex infrastructure and maintenance. Vent to atmosphere setups are simpler and less expensive to install, allowing for quick pressure relief, but they release pollutants directly, potentially violating regulations and increasing environmental harm. Selecting between these depends on balancing efficiency, compliance requirements, and capital expenditure.

Choosing the Right Blow Off Valve for Your Vehicle

Choosing the right blow off valve for your vehicle depends on your performance goals and environmental considerations. Recirculating blow off valves redirect excess boost pressure back into the intake system, improving turbocharger efficiency and reducing turbo lag while minimizing noise and emissions. Vent to atmosphere valves release pressure into the surrounding air, creating a distinctive sound favored by enthusiasts but potentially increasing noise pollution and negatively impacting engine performance.

recirculating blow off vs vent to atmosphere Infographic

libmatt.com

libmatt.com