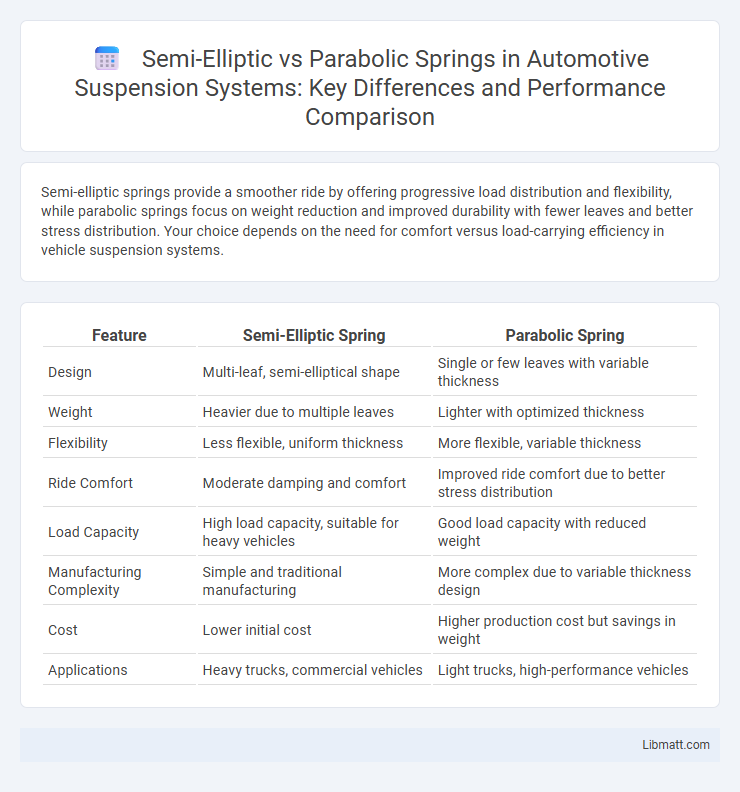

Semi-elliptic springs provide a smoother ride by offering progressive load distribution and flexibility, while parabolic springs focus on weight reduction and improved durability with fewer leaves and better stress distribution. Your choice depends on the need for comfort versus load-carrying efficiency in vehicle suspension systems.

Table of Comparison

| Feature | Semi-Elliptic Spring | Parabolic Spring |

|---|---|---|

| Design | Multi-leaf, semi-elliptical shape | Single or few leaves with variable thickness |

| Weight | Heavier due to multiple leaves | Lighter with optimized thickness |

| Flexibility | Less flexible, uniform thickness | More flexible, variable thickness |

| Ride Comfort | Moderate damping and comfort | Improved ride comfort due to better stress distribution |

| Load Capacity | High load capacity, suitable for heavy vehicles | Good load capacity with reduced weight |

| Manufacturing Complexity | Simple and traditional manufacturing | More complex due to variable thickness design |

| Cost | Lower initial cost | Higher production cost but savings in weight |

| Applications | Heavy trucks, commercial vehicles | Light trucks, high-performance vehicles |

Introduction to Suspension Systems

Semi-elliptic springs, commonly used in suspension systems, consist of layered steel strips forming a curved, leaf-like shape, providing durability and load-bearing capacity ideal for heavy vehicles. Parabolic springs, designed with tapered leaves, deliver a smoother ride and reduced weight by offering variable stiffness that improves shock absorption in modern automotive suspensions. Your vehicle's suspension performance depends significantly on the choice between these springs, balancing ride comfort and load support.

Overview of Semi-Elliptic Springs

Semi-elliptic springs, also known as leaf springs, consist of multiple layers of metal strips stacked in a curved shape, providing excellent load distribution and shock absorption for vehicle suspension systems. These springs offer durability and are commonly used in trucks and heavy-duty vehicles due to their ability to support heavy loads while maintaining ride comfort. Your choice between semi-elliptic and parabolic springs depends on factors like weight capacity, ride smoothness, and manufacturing costs.

Overview of Parabolic Springs

Parabolic springs feature variable thickness along their length, resulting in reduced weight and improved stress distribution compared to semi-elliptic springs. These springs provide enhanced ride comfort and durability due to their optimized geometry, which allows for better load-bearing capacity and flexibility. Commonly used in heavy-duty vehicles, parabolic springs contribute to fuel efficiency and extended suspension life.

Design Differences: Semi-Elliptic vs Parabolic

Semi-elliptic springs feature multiple steel leaves stacked in a graduated length, forming a layered arc that provides flexibility and load distribution. Parabolic springs, by contrast, use fewer leaves with variable thickness, tapering from the center to the ends, optimizing weight reduction and enhancing durability. The design of parabolic springs offers improved ride comfort and reduced unsprung mass compared to the traditional semi-elliptic configuration.

Ride Comfort and Handling Comparison

Semi-elliptic springs typically provide a stiffer ride due to their simple leaf spring design, resulting in less effective absorption of road irregularities and thus reduced ride comfort compared to parabolic springs. Parabolic springs feature tapered leaves that flex more uniformly under load, enhancing shock absorption and delivering superior ride comfort while maintaining good handling characteristics. Vehicles equipped with parabolic springs generally experience improved road grip and stability, offering a balanced combination of smoother ride quality and reliable handling performance.

Load Capacity and Performance

Semi-elliptic springs provide higher load capacity due to their multiple leaf layers distributing weight evenly, making them suitable for heavy-duty vehicles. Parabolic springs offer improved performance through reduced weight and enhanced flexibility, resulting in better ride comfort and durability under dynamic loads. The choice between the two depends on balancing maximum load requirements with desired ride quality and suspension responsiveness.

Maintenance and Durability

Semi-elliptic springs require regular lubrication and periodic inspection for leaf wear to maintain optimal performance, making their maintenance relatively intensive. Parabolic springs, designed with variable thickness leaves, offer improved durability and reduced weight, leading to less frequent maintenance needs and enhanced fatigue resistance. Choosing the right spring impacts Your vehicle's longevity and maintenance costs, with parabolic springs generally providing a more durable and low-maintenance solution.

Weight and Fuel Efficiency

Semi-elliptic springs typically weigh more than parabolic springs due to their multiple layered plates, which increases the overall vehicle weight and can reduce fuel efficiency. Parabolic springs use fewer layers with variable thickness, resulting in a lighter suspension system that contributes to improved fuel economy by reducing the load on the engine. The reduced unsprung weight from parabolic springs enhances vehicle dynamics and lowers fuel consumption compared to the heavier semi-elliptic design.

Applications in Modern Vehicles

Semi-elliptic springs are primarily used in heavy-duty trucks and commercial vehicles due to their robustness and ability to handle heavy loads. Parabolic springs offer improved ride comfort and are increasingly found in passenger cars and light trucks where weight reduction and suspension performance are critical. Modern vehicles prioritize parabolic springs for better suspension articulation and fuel efficiency, while semi-elliptic springs remain prevalent in applications demanding durability and load-carrying capacity.

Choosing the Right Spring for Your Needs

When choosing the right spring for your needs, consider the load capacity and ride comfort requirements; semi-elliptic springs provide better load distribution and durability, making them ideal for heavy-duty applications, while parabolic springs offer improved flexibility and lighter weight for enhanced ride quality. Your vehicle's suspension system benefits from semi-elliptic springs by reducing stress on chassis components, whereas parabolic springs optimize performance in light to medium load scenarios. Match the spring type to your specific application to ensure optimal balance between strength, weight, and comfort.

semi-elliptic vs parabolic spring Infographic

libmatt.com

libmatt.com