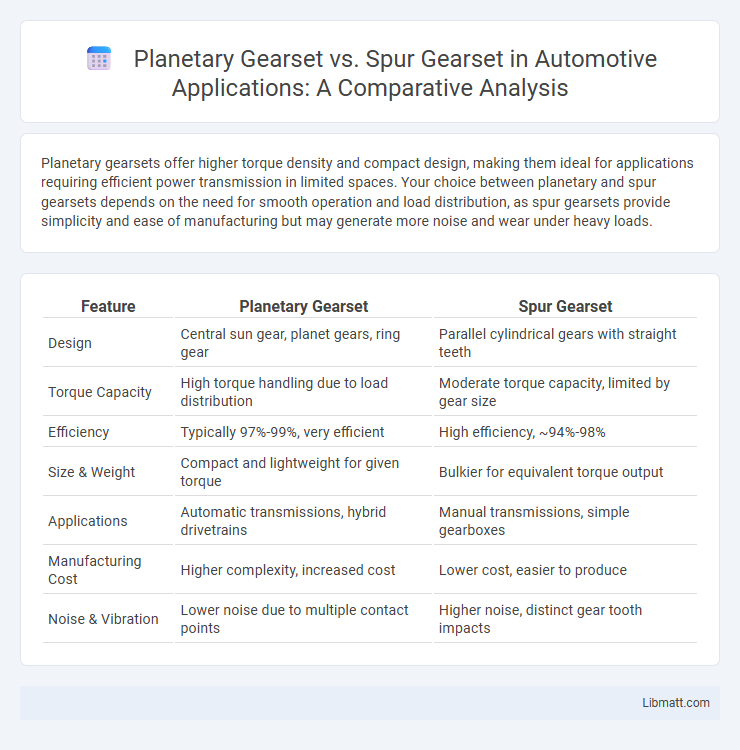

Planetary gearsets offer higher torque density and compact design, making them ideal for applications requiring efficient power transmission in limited spaces. Your choice between planetary and spur gearsets depends on the need for smooth operation and load distribution, as spur gearsets provide simplicity and ease of manufacturing but may generate more noise and wear under heavy loads.

Table of Comparison

| Feature | Planetary Gearset | Spur Gearset |

|---|---|---|

| Design | Central sun gear, planet gears, ring gear | Parallel cylindrical gears with straight teeth |

| Torque Capacity | High torque handling due to load distribution | Moderate torque capacity, limited by gear size |

| Efficiency | Typically 97%-99%, very efficient | High efficiency, ~94%-98% |

| Size & Weight | Compact and lightweight for given torque | Bulkier for equivalent torque output |

| Applications | Automatic transmissions, hybrid drivetrains | Manual transmissions, simple gearboxes |

| Manufacturing Cost | Higher complexity, increased cost | Lower cost, easier to produce |

| Noise & Vibration | Lower noise due to multiple contact points | Higher noise, distinct gear tooth impacts |

Introduction to Gearset Types

Planetary gearsets feature a central sun gear surrounded by multiple planet gears rotating inside a ring gear, enabling compact design and high torque density. Spur gearsets consist of parallel gears with straight teeth, offering simplicity and efficiency for transmitting motion between parallel shafts. Understanding your application requirements helps determine whether the durability and load distribution of planetary gears or the straightforward design of spur gears best suits your mechanical system.

Overview of Planetary Gearsets

Planetary gearsets feature a central sun gear, multiple planet gears, and an outer ring gear, creating a compact and robust mechanism ideal for high torque transmission and variable speed ratios. These gearsets provide superior load distribution, increased torque density, and enhanced efficiency compared to spur gearsets, making them essential in automotive transmissions and industrial machinery. Their ability to achieve multiple gear ratios within a single assembly enables smooth power delivery and versatility in complex mechanical systems.

Overview of Spur Gearsets

Spur gearsets consist of gears with straight teeth mounted on parallel shafts, offering simple design and efficient power transmission. They provide precise speed ratios and are widely used in applications requiring moderate speeds and loads due to their straightforward manufacturing and low cost. Spur gearsets tend to generate more noise and stress on gear teeth compared to planetary gearsets, making them less ideal for high-torque or compact space requirements.

Key Components and Structure

Planetary gearsets consist of a central sun gear, multiple planet gears mounted on a rotating carrier, and an outer ring gear with internal teeth, creating a compact and efficient structure for distributing torque. Spur gearsets feature parallel shafts with straight-cut teeth on gears meshing directly, offering simplicity and ease of manufacturing. Understanding the key components and structural differences helps you choose the right gearset for specific applications requiring varying torque, speed, and size constraints.

Efficiency Comparison

Planetary gearsets generally exhibit higher efficiency than spur gearsets due to their load distribution over multiple planet gears, reducing stress and friction losses. Efficiency in planetary gear systems typically ranges from 95% to 98%, while spur gearsets often achieve around 94% to 96%. The compact design of planetary gearsets also minimizes energy loss, making them a superior choice for high-performance and space-constrained applications.

Load Distribution Differences

Planetary gearsets distribute load evenly across multiple planet gears, enhancing torque capacity and durability under high-stress conditions, which is beneficial for applications requiring compact design and high efficiency. Spur gearsets concentrate load on fewer gear teeth, making them simpler but prone to higher stress and wear under heavy loads, limiting their suitability for high-torque scenarios. Understanding these load distribution differences helps optimize your choice for mechanical systems requiring either precision or robust load handling.

Applications in Industry

Planetary gearsets are extensively used in automotive transmissions, aerospace mechanisms, and industrial machinery due to their compact design, high torque density, and ability to distribute load evenly across multiple gears. Spur gearsets find applications in conveyors, simple mechanical equipment, and low-speed machinery where cost-effectiveness and ease of manufacturing are critical. Your choice between these gearsets depends on the required torque, space constraints, and operational efficiency in specific industrial environments.

Space and Compactness Factors

Planetary gearsets offer superior space efficiency due to their coaxial design, allowing multiple gears to be nested within a compact housing, which significantly reduces the overall footprint compared to spur gearsets. Spur gearsets require more linear space since their gears are arranged side-by-side, making them less suitable for applications where compactness is critical. The compact arrangement of planetary gears enables higher power density and better load distribution in limited spaces, enhancing overall mechanical performance in space-constrained environments.

Noise and Vibration Analysis

Planetary gearsets exhibit lower noise and vibration levels compared to spur gearsets due to their balanced load distribution and continuous tooth engagement, which reduces impact forces and gear meshing noise. Spur gearsets tend to generate higher noise and vibration because of their intermittent tooth contact and higher impact stresses during meshing. Advanced noise and vibration analysis often shows that planetary gear systems provide smoother operation, making them preferable in applications requiring quiet and stable performance.

Cost Considerations and Maintenance

Planetary gearsets typically offer higher torque density and compact design but come with increased manufacturing complexity, leading to higher initial costs compared to spur gearsets. Spur gearsets are generally more affordable and easier to produce, making them a cost-effective choice for applications where space and torque demands are lower. Your maintenance efforts may be simpler and less frequent with spur gearsets due to their straightforward design, while planetary gearsets often require more precise lubrication and inspection to ensure long-term reliability.

Planetary Gearset vs Spur Gearset Infographic

libmatt.com

libmatt.com