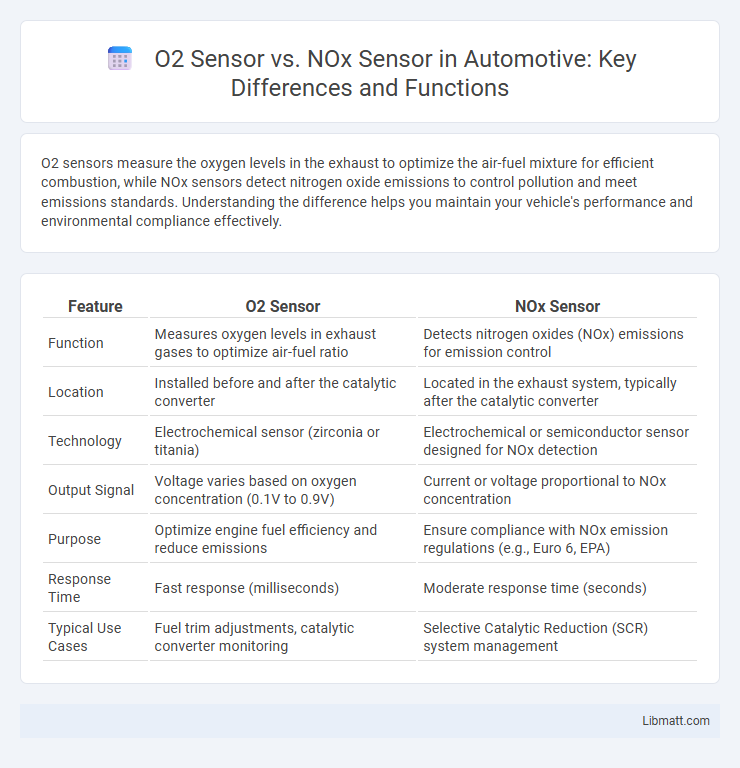

O2 sensors measure the oxygen levels in the exhaust to optimize the air-fuel mixture for efficient combustion, while NOx sensors detect nitrogen oxide emissions to control pollution and meet emissions standards. Understanding the difference helps you maintain your vehicle's performance and environmental compliance effectively.

Table of Comparison

| Feature | O2 Sensor | NOx Sensor |

|---|---|---|

| Function | Measures oxygen levels in exhaust gases to optimize air-fuel ratio | Detects nitrogen oxides (NOx) emissions for emission control |

| Location | Installed before and after the catalytic converter | Located in the exhaust system, typically after the catalytic converter |

| Technology | Electrochemical sensor (zirconia or titania) | Electrochemical or semiconductor sensor designed for NOx detection |

| Output Signal | Voltage varies based on oxygen concentration (0.1V to 0.9V) | Current or voltage proportional to NOx concentration |

| Purpose | Optimize engine fuel efficiency and reduce emissions | Ensure compliance with NOx emission regulations (e.g., Euro 6, EPA) |

| Response Time | Fast response (milliseconds) | Moderate response time (seconds) |

| Typical Use Cases | Fuel trim adjustments, catalytic converter monitoring | Selective Catalytic Reduction (SCR) system management |

Introduction to O2 and NOx Sensors

O2 sensors measure oxygen levels in exhaust gases to optimize air-fuel mixture for efficient combustion and reduced emissions, primarily detecting oxygen concentration. NOx sensors specifically monitor nitrogen oxides (NO and NO2) in exhaust emissions, playing a critical role in controlling harmful pollutants and ensuring compliance with environmental regulations. Both sensors provide essential feedback to engine control units for emission control but target different gases and operate using distinct detection technologies.

Purpose and Function of O2 Sensors

O2 sensors measure the oxygen level in your vehicle's exhaust gases to optimize the air-fuel mixture for efficient combustion and reduced emissions. They provide real-time feedback to the engine control unit (ECU) to maintain optimal fuel efficiency and performance. Unlike NOx sensors that specifically detect nitrogen oxide emissions, O2 sensors primarily ensure your engine runs efficiently by monitoring oxygen content.

Purpose and Function of NOx Sensors

NOx sensors measure nitrogen oxides in exhaust gases to optimize emissions control and engine performance, playing a crucial role in meeting stringent environmental regulations. Unlike O2 sensors that detect oxygen levels to adjust air-fuel mixtures, NOx sensors monitor NO and NO2 concentrations to manage selective catalytic reduction (SCR) systems effectively. Accurate NOx sensing ensures reduced harmful emissions, enhancing fuel efficiency and compliance with Euro 6 and Tier 3 standards.

Key Differences Between O2 and NOx Sensors

O2 sensors measure oxygen levels in the exhaust to optimize air-fuel ratio and improve engine efficiency, while NOx sensors detect nitrogen oxide emissions to help reduce harmful pollutants. Your vehicle's emission control system relies on O2 sensors for fuel combustion monitoring, whereas NOx sensors are crucial for meeting strict environmental regulations by managing NOx aftertreatment systems. The distinct measurement focus and role in emission control highlight the key functional differences between these two critical sensors.

Sensor Placement in Automotive Systems

O2 sensors are typically positioned in the exhaust manifold or close to the engine to monitor oxygen levels for fuel-air mixture adjustments. NOx sensors are strategically placed downstream, often near the selective catalytic reduction (SCR) system, to detect nitrogen oxide emissions for emission control. Your vehicle's emission system relies on precise placement of both sensors to optimize engine performance and reduce pollutants.

Technology and Sensing Mechanisms

O2 sensors use zirconia or titania elements to measure oxygen levels in exhaust gases through voltage changes or resistance shifts, providing feedback for optimal air-fuel mixture control. NOx sensors employ electrochemical cells or resistive sensors to detect nitrogen oxide concentrations by measuring ionic conductivity or resistance variations, critical for emissions control and Selective Catalytic Reduction (SCR) systems. Understanding these distinct sensing mechanisms helps you choose the right sensor technology for accurate vehicle emissions monitoring and regulatory compliance.

Impact on Emission Control and Regulations

O2 sensors measure oxygen levels in the exhaust to optimize air-fuel ratios, directly influencing catalytic converter efficiency and reducing CO and HC emissions. NOx sensors detect nitrogen oxide concentrations, enabling precise adjustments in exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems to meet stringent NOx emission standards. Both sensors are crucial for compliance with regulations such as Euro 6 and EPA Tier 3, ensuring vehicles maintain low pollutant levels and improved air quality.

Common Symptoms of Sensor Failure

O2 sensor failure often causes rough engine idling, increased fuel consumption, and illuminated check engine lights due to inaccurate oxygen level readings affecting the air-fuel mixture. NOx sensor failure typically results in poor emission control, failed emissions tests, and reduced engine performance as the system cannot accurately monitor nitrogen oxide levels. Understanding these symptoms helps you diagnose sensor issues promptly to maintain optimal engine efficiency and emissions compliance.

Maintenance and Replacement Considerations

O2 sensors typically require maintenance or replacement every 60,000 to 90,000 miles due to contamination or aging that affects fuel efficiency and emissions control. NOx sensors have a shorter lifespan, often needing replacement around 50,000 to 70,000 miles, as they operate in high-temperature environments that accelerate wear. Proper maintenance of both sensor types is critical for optimal engine performance, emission compliance, and avoiding costly repairs.

Choosing the Right Sensor for Your Vehicle

Choosing the right sensor for your vehicle depends on the specific emissions and performance needs. An O2 sensor monitors oxygen levels in the exhaust to optimize fuel efficiency and reduce emissions, while a NOx sensor detects nitrogen oxide levels to ensure compliance with stricter environmental regulations. Understanding your vehicle's requirements and regulatory standards will help you determine whether an O2 sensor or NOx sensor is essential for optimal engine management and air quality control.

O2 sensor vs NOx sensor Infographic

libmatt.com

libmatt.com