A torque tube offers increased rigidity and alignment by enclosing the drive shaft, reducing vibration and improving drivetrain efficiency compared to a traditional exposed drive shaft. Your vehicle benefits from enhanced durability and better power transfer with a torque tube system, especially in high-performance or off-road applications.

Table of Comparison

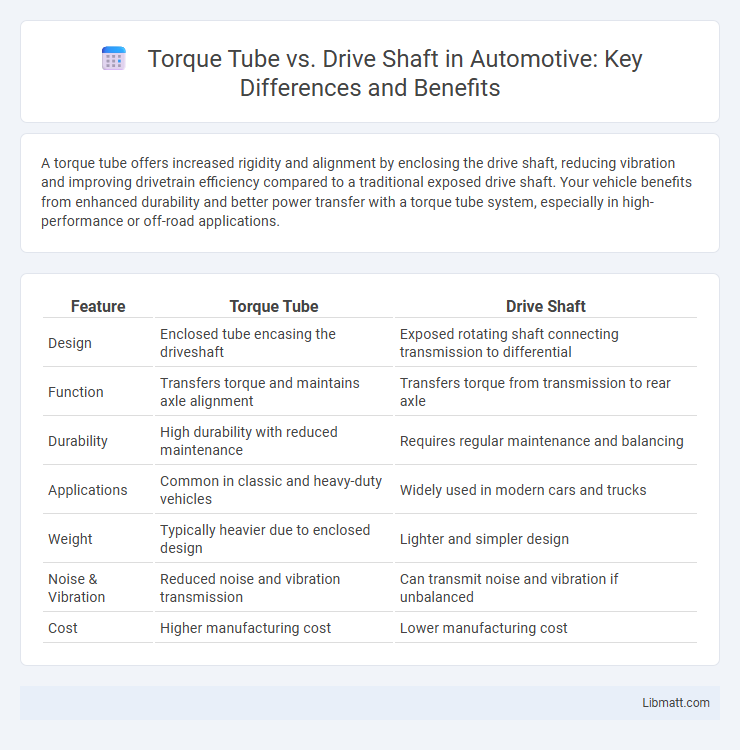

| Feature | Torque Tube | Drive Shaft |

|---|---|---|

| Design | Enclosed tube encasing the driveshaft | Exposed rotating shaft connecting transmission to differential |

| Function | Transfers torque and maintains axle alignment | Transfers torque from transmission to rear axle |

| Durability | High durability with reduced maintenance | Requires regular maintenance and balancing |

| Applications | Common in classic and heavy-duty vehicles | Widely used in modern cars and trucks |

| Weight | Typically heavier due to enclosed design | Lighter and simpler design |

| Noise & Vibration | Reduced noise and vibration transmission | Can transmit noise and vibration if unbalanced |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

Introduction to Torque Tube and Drive Shaft Systems

Torque tube and drive shaft systems are essential components in vehicle drivetrains, transmitting power from the engine to the wheels efficiently. A torque tube encases the drive shaft, providing structural support and reducing vibration, commonly found in rear-wheel-drive and some off-road vehicles. Your choice between a torque tube and a traditional drive shaft depends on factors like durability, maintenance, and vehicle design preferences.

Key Differences Between Torque Tube and Drive Shaft

Torque tubes enclose the drive shaft within a rigid housing that transmits torque and maintains alignment between the transmission and rear axle, providing structural support and reducing drivetrain vibration. Drive shafts are exposed rotating components that directly transfer rotational power from the transmission to the differential without additional structural containment. Torque tubes offer enhanced drivetrain rigidity and alignment control, while drive shafts prioritize simplicity and ease of maintenance.

How Torque Tube Mechanisms Work

Torque tube mechanisms work by enclosing the drive shaft within a rigid tube that connects the transmission to the rear axle, effectively transmitting torque while maintaining alignment and managing torsional forces. This enclosed design reduces driveline vibrations and enhances stability by distributing torque evenly across the vehicle's frame. Your vehicle benefits from smoother power delivery and increased durability compared to traditional open drive shaft systems.

How Drive Shaft Systems Function

Drive shaft systems transfer rotational power from the engine or transmission to the differential, enabling vehicle wheels to turn. They consist of a rotating shaft connected by universal joints that accommodate movement and alignment variations between components. Torque tubes, in contrast, encase the drive shaft within a rigid tube, providing structural support and reducing torque reaction, but drive shafts alone mainly focus on efficient rotational power transmission.

Advantages of Torque Tube Design

Torque tube design offers superior torsional rigidity and alignment stability, enhancing drivetrain efficiency and reducing vibrations compared to conventional drive shafts. This enclosed structure protects the drive components from debris and impacts, extending the lifespan of the powertrain. Furthermore, torque tubes provide improved load distribution and support, which contributes to better vehicle handling and durability in demanding applications.

Benefits of Conventional Drive Shaft Setup

A conventional drive shaft setup offers improved flexibility and easier maintenance compared to torque tubes, allowing You to quickly replace or service components without extensive disassembly. This configuration reduces unsprung weight, enhancing suspension performance and vehicle handling. Drive shafts also accommodate larger power outputs efficiently, making them ideal for high-performance and off-road applications.

Common Applications: Torque Tube vs Drive Shaft

Torque tubes are commonly used in heavy-duty vehicles, agricultural machinery, and classic cars where enhanced structural rigidity and precise alignment of the drivetrain are essential. Drive shafts are prevalent in modern passenger cars, trucks, and off-road vehicles due to their flexibility, ease of maintenance, and ability to accommodate suspension movement. The choice between torque tube and drive shaft applications depends on vehicle design requirements, load capacity, and chassis configuration.

Maintenance and Durability Considerations

Torque tubes typically offer greater durability due to their enclosed design, which protects internal components from dirt and damage, reducing maintenance needs. Drive shafts require regular inspection and lubrication of universal joints to prevent wear and potential failure, increasing maintenance frequency. You can expect torque tubes to provide a longer service life with less routine upkeep compared to drive shafts, especially in harsh driving conditions.

Performance Impact and Handling Comparison

Torque tubes provide improved drivetrain rigidity by enclosing the drive shaft, which reduces vibrations and enhances vehicle stability during acceleration and cornering. Drive shafts, being lighter and simpler, allow for quicker rotational response but may introduce slight driveline lash, potentially affecting precision in handling. Your choice between torque tube and drive shaft configurations significantly influences performance dynamics, with torque tubes favoring smoother power delivery and drive shafts enabling more direct, responsive handling.

Choosing the Right System: Factors to Consider

Selecting between a torque tube and drive shaft system depends on vehicle type, performance needs, and maintenance preferences. Torque tubes provide enhanced alignment and structural rigidity, ideal for classic or heavy-duty vehicles, while drive shafts offer simpler design and easier replacement, suited for modern cars and trucks. Consider factors like weight distribution, drivetrain layout, and service accessibility to determine the optimal torque transmission method.

torque tube vs drive shaft Infographic

libmatt.com

libmatt.com