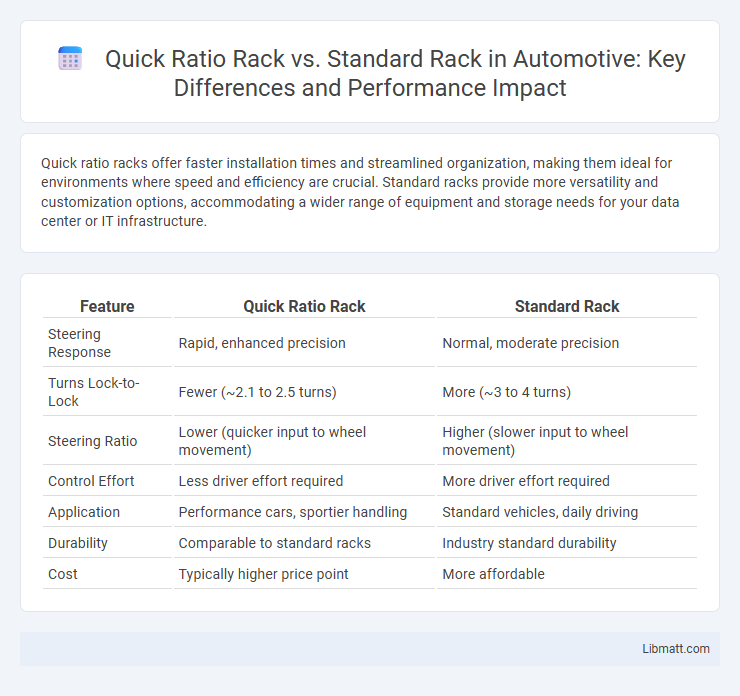

Quick ratio racks offer faster installation times and streamlined organization, making them ideal for environments where speed and efficiency are crucial. Standard racks provide more versatility and customization options, accommodating a wider range of equipment and storage needs for your data center or IT infrastructure.

Table of Comparison

| Feature | Quick Ratio Rack | Standard Rack |

|---|---|---|

| Steering Response | Rapid, enhanced precision | Normal, moderate precision |

| Turns Lock-to-Lock | Fewer (~2.1 to 2.5 turns) | More (~3 to 4 turns) |

| Steering Ratio | Lower (quicker input to wheel movement) | Higher (slower input to wheel movement) |

| Control Effort | Less driver effort required | More driver effort required |

| Application | Performance cars, sportier handling | Standard vehicles, daily driving |

| Durability | Comparable to standard racks | Industry standard durability |

| Cost | Typically higher price point | More affordable |

Introduction to Steering Racks

Quick ratio racks offer faster steering response by reducing the number of turns lock-to-lock, enhancing maneuverability compared to standard racks. Standard steering racks provide a balanced steering feel with a higher turn count, prioritizing precision and comfort over speed. Your choice between quick ratio and standard racks impacts vehicle handling characteristics, especially in performance or daily driving scenarios.

What is a Quick Ratio Rack?

A Quick Ratio Rack is a specialized storage system designed for rapid access and efficient organization of materials, often used in warehouses or manufacturing environments. Unlike a standard rack, which focuses primarily on maximizing storage capacity, a Quick Ratio Rack prioritizes speed and ease of retrieval to improve workflow efficiency. Your operations can benefit from this system by reducing downtime and streamlining inventory management.

What is a Standard Rack?

A Standard Rack, often measuring 42U in height, is a widely used shelving unit designed to house networking equipment, servers, and other electronic hardware. It provides a structured framework with fixed dimensions and mounting holes, ensuring compatibility with industry-standard devices. Unlike Quick Ratio Racks, Standard Racks emphasize stability and modularity for data centers and IT environments.

Key Differences: Quick Ratio vs Standard Rack

Quick ratio racks offer significantly faster assembly and disassembly times compared to standard racks, increasing operational efficiency in storage management. They utilize modular components and simplified locking mechanisms, reducing labor costs and downtime during installation or reconfiguration. Standard racks prioritize structural robustness and load capacity but require more time and tools for setup, making quick ratio racks ideal for dynamic environments demanding rapid adaptability.

Steering Response and Precision

Quick ratio racks enhance steering response by reducing the number of turns lock-to-lock, allowing for faster, more direct wheel input and greater precision in maneuvering. Standard racks have a slower steering ratio, which can result in less immediate feedback and slightly reduced accuracy during sharp turns. Performance vehicles and enthusiasts often prefer quick ratio racks for their superior control and sharper handling characteristics.

Impact on Driving Experience

Quick ratio racks provide more immediate and precise steering feedback, enhancing vehicle responsiveness and control during dynamic driving. Standard racks offer smoother, more gradual steering input, which can improve comfort but may reduce the feeling of connection with the road. The choice between quick and standard racks directly influences handling characteristics, driver confidence, and overall driving engagement.

Performance Applications

Quick ratio racks deliver superior performance in high-demand applications by enabling faster access and efficient handling of materials compared to standard racks. Your operational efficiency improves significantly due to reduced picking times and enhanced space utilization, ideal for industries requiring rapid inventory turnover. These racks excel in environments like warehouses and manufacturing plants where speed and reliability directly impact productivity.

Installation and Compatibility Considerations

Quick ratio racks offer simplified installation with tool-free assembly and modular components, minimizing setup time and labor costs compared to standard racks that often require bolts and precise alignment. Compatibility is enhanced in quick ratio racks through adjustable shelving and universal fittings suitable for diverse equipment sizes, whereas standard racks may have fixed dimensions limiting flexibility. These features make quick ratio racks preferable for dynamic environments demanding efficient space utilization and rapid configuration changes.

Pros and Cons of Quick Ratio Racks

Quick ratio racks offer faster assembly and disassembly compared to standard racks, significantly reducing installation time and labor costs. However, their complex design can result in higher initial investment and potential compatibility issues with existing warehouse systems. Standard racks provide greater load capacity and durability but require more time and effort to install or modify.

Choosing the Right Steering Rack for Your Vehicle

Selecting the right steering rack hinges on your vehicle's performance needs and maintenance preferences. Quick ratio racks offer sharper, more responsive steering often favored in sports and performance cars, providing quicker turns with less steering wheel rotation. Standard racks deliver smoother, more controlled steering suitable for everyday driving, prioritizing stability and comfort over aggressive handling.

quick ratio rack vs standard rack Infographic

libmatt.com

libmatt.com