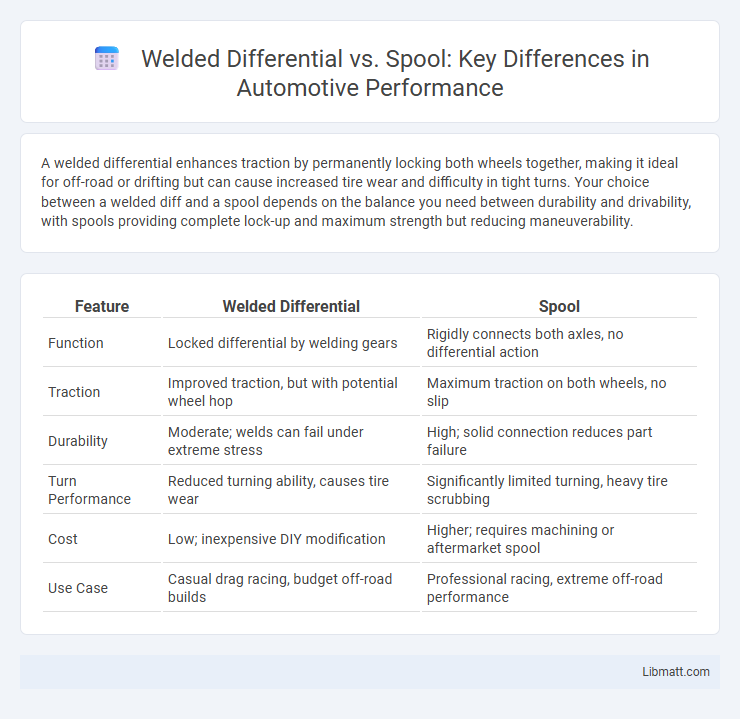

A welded differential enhances traction by permanently locking both wheels together, making it ideal for off-road or drifting but can cause increased tire wear and difficulty in tight turns. Your choice between a welded diff and a spool depends on the balance you need between durability and drivability, with spools providing complete lock-up and maximum strength but reducing maneuverability.

Table of Comparison

| Feature | Welded Differential | Spool |

|---|---|---|

| Function | Locked differential by welding gears | Rigidly connects both axles, no differential action |

| Traction | Improved traction, but with potential wheel hop | Maximum traction on both wheels, no slip |

| Durability | Moderate; welds can fail under extreme stress | High; solid connection reduces part failure |

| Turn Performance | Reduced turning ability, causes tire wear | Significantly limited turning, heavy tire scrubbing |

| Cost | Low; inexpensive DIY modification | Higher; requires machining or aftermarket spool |

| Use Case | Casual drag racing, budget off-road builds | Professional racing, extreme off-road performance |

Introduction to Welded Diffs and Spools

Welded differentials and spools are both drivetrain components used to improve traction by locking the axle shafts together, ensuring both wheels rotate at the same speed. Welded diffs are created by permanently fusing the internal gears of a standard differential, making it a cost-effective solution for off-road vehicles and drag racing. Spools, on the other hand, replace the entire differential carrier, offering a stronger and more durable option especially favored in heavy-duty applications and hardcore racing environments.

What is a Welded Differential?

A Welded Differential is a modification that locks the differential by welding the spider gears together, ensuring both wheels rotate at the same speed. This setup enhances traction in off-road or racing conditions by preventing wheel slip commonly seen in open differentials. Your vehicle benefits from improved grip during aggressive driving but may experience increased tire wear and reduced turning efficiency on regular roads.

Understanding Spool Differentials

Spool differentials lock both axles together, forcing them to rotate at the same speed, which enhances traction in off-road and racing scenarios. Unlike welded differentials that weld the spider gears, spools replace the entire differential mechanism, providing a more robust and durable solution for extreme conditions. Your vehicle benefits from improved power distribution and reduced drivetrain wear with a spool differential, though it may cause increased tire wear and difficulty in tight turns.

Welded Diff vs Spool: Key Differences

A welded differential permanently fuses both drive wheels to spin at the same speed, enhancing traction but causing tire wear and difficult handling during turns. A spool replaces the differential entirely, locking both axles together for maximum power transfer and durability, commonly used in racing or off-road applications. Key differences include the welded diff retaining some differential housing components for partial flexibility, while the spool eliminates all differential action for a solid connection.

Performance Impact: Welded Diff vs Spool

A welded differential locks both axle shafts together, improving traction but causing tire hop and increased drivetrain wear during turns, impacting handling negatively on paved surfaces. In contrast, a spool permanently locks the axles, providing maximum traction and durability with zero slippage but sacrificing steering precision and increasing tire scrub. Performance in off-road scenarios favors spools for consistent power delivery, while welded diffs offer a balance between traction and vehicle control.

Cost Comparison: Welded Diff vs Spool

Welded differentials generally offer a lower initial cost compared to spools due to simpler manufacturing and installation processes. Spools, while more expensive upfront, provide higher durability and consistent performance, potentially reducing long-term maintenance expenses. Evaluating the total cost of ownership involves balancing the lower purchase price of welded diffs against the reliability and longevity of spools in demanding applications.

Durability and Maintenance Considerations

Welded differentials offer superior durability by permanently locking the axle halves together, reducing the risk of gear slippage under heavy loads or off-road conditions. However, this increased strength comes with higher maintenance demands, as any damage requires cutting and rewelding, making repairs more labor-intensive and costly. In contrast, spools provide consistent power delivery with easier installation and maintenance but may wear out faster due to more moving components and typically require more frequent servicing.

Pros and Cons: Welded Diff

Welded diffs provide superior traction by locking both wheels together, making them ideal for off-road and drag racing applications where maximum grip is crucial. However, they can cause excessive tire wear and strain on drivetrain components during regular street driving due to the lack of differential action in turns. Your choice depends on whether you prioritize enhanced traction or smoother handling and longevity for everyday use.

Pros and Cons: Spool Differential

Spool differentials offer maximum traction by locking both wheels to rotate at the same speed, ideal for drag racing or off-road use where wheel slip is undesirable. However, they can cause increased tire wear and reduced maneuverability during tight turns, making them less suitable for street driving. Your choice depends on whether you prioritize straight-line performance or everyday drivability.

Which is Better for Your Application?

A welded differential offers increased strength and durability, making it ideal for high-performance or off-road applications where traction is critical. A spool connects both axles rigidly, providing maximum power transfer but sacrificing turn ease and drivability on pavement. Your choice should balance strength needs with daily driving comfort to select the optimal differential type for your specific vehicle use.

welded diff vs spool Infographic

libmatt.com

libmatt.com