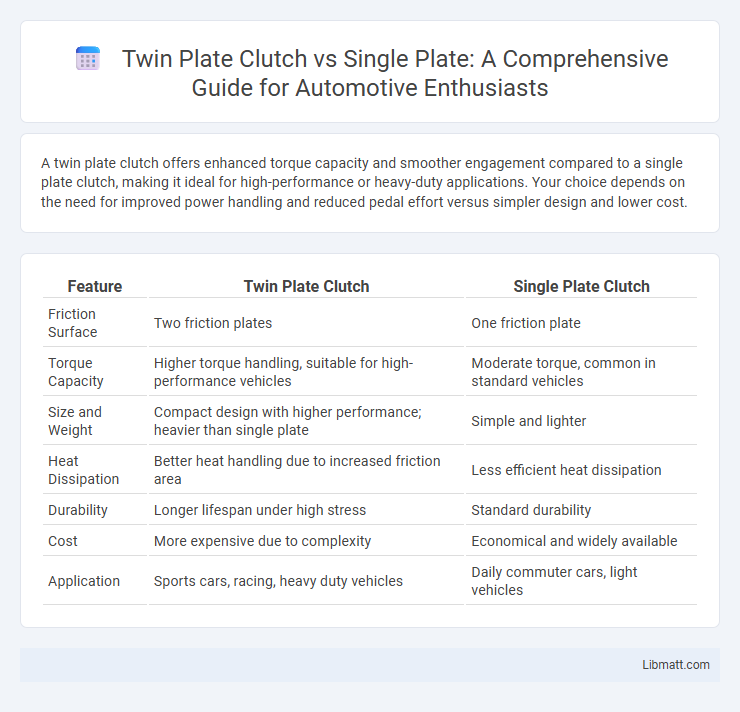

A twin plate clutch offers enhanced torque capacity and smoother engagement compared to a single plate clutch, making it ideal for high-performance or heavy-duty applications. Your choice depends on the need for improved power handling and reduced pedal effort versus simpler design and lower cost.

Table of Comparison

| Feature | Twin Plate Clutch | Single Plate Clutch |

|---|---|---|

| Friction Surface | Two friction plates | One friction plate |

| Torque Capacity | Higher torque handling, suitable for high-performance vehicles | Moderate torque, common in standard vehicles |

| Size and Weight | Compact design with higher performance; heavier than single plate | Simple and lighter |

| Heat Dissipation | Better heat handling due to increased friction area | Less efficient heat dissipation |

| Durability | Longer lifespan under high stress | Standard durability |

| Cost | More expensive due to complexity | Economical and widely available |

| Application | Sports cars, racing, heavy duty vehicles | Daily commuter cars, light vehicles |

Introduction to Clutch Types

Twin plate clutch systems offer increased torque capacity and smoother engagement compared to single plate clutches, making them ideal for high-performance or heavy-duty vehicles. Single plate clutches provide simplicity, lighter weight, and cost-effectiveness, suitable for everyday driving and moderate power applications. Your choice depends on the performance demands and durability requirements of your vehicle.

What is a Single Plate Clutch?

A single plate clutch utilizes one friction disc between the engine flywheel and pressure plate to transmit power, offering simplicity and efficient torque transfer for standard vehicle applications. Its compact design ensures lighter weight and easier maintenance compared to twin plate clutches, making it ideal for regular driving conditions. Single plate clutches are commonly found in passenger cars where smooth engagement and fuel efficiency are prioritized.

What is a Twin Plate Clutch?

A twin plate clutch features two friction plates instead of one, increasing the friction surface area and allowing higher torque transmission compared to a single plate clutch. This design improves performance in high-power vehicles by enhancing heat dissipation and reducing clutch wear. Twin plate clutches are commonly used in motorcycles, racing cars, and heavy-duty machinery where efficient power handling and durability are critical.

Key Differences Between Twin Plate and Single Plate Clutches

Twin plate clutches feature two friction discs, providing greater surface area for torque transmission compared to the single friction disc in single plate clutches, enhancing load capacity and heat dissipation. Single plate clutches are simpler, lighter, and more cost-effective, suited for standard vehicles with moderate power demands, while twin plate clutches support higher performance applications, including sports cars and heavy-duty vehicles. Twin plate designs also deliver smoother engagement and reduced pedal effort, improving driver control and comfort in high-torque scenarios.

Performance Comparison: Twin Plate vs Single Plate

Twin plate clutches offer enhanced torque capacity and smoother engagement compared to single plate clutches, making them ideal for high-performance or heavy-duty applications. Single plate clutches provide lighter weight and simpler design, delivering quicker response but lower torque tolerance. Your choice depends on whether you prioritize maximum performance and durability or cost-effectiveness and ease of maintenance.

Durability and Longevity Considerations

Twin plate clutches offer enhanced durability due to increased friction surface area, distributing stress more evenly and reducing wear compared to single plate clutches. The additional plate in twin plate clutches allows for better heat dissipation, which prolongs component lifespan under high-torque and frequent engagement conditions. Single plate clutches, while simpler and lighter, often experience faster wear rates and require more frequent maintenance in demanding applications.

Cost Analysis: Twin Plate vs Single Plate

Twin plate clutches generally have a higher initial cost than single plate clutches due to their complex design and additional friction surfaces, which require more materials and manufacturing precision. Maintenance expenses for twin plate clutches can be greater as well, given their increased wear points and potential for more frequent adjustments. Despite higher upfront and maintenance costs, twin plate clutches offer superior torque capacity and durability, often justifying the investment in high-performance or heavy-duty applications.

Ideal Applications for Each Clutch Type

Twin plate clutches are ideal for high-performance vehicles and motorcycles requiring greater torque capacity and smoother engagement under demanding conditions, such as racing cars and heavy-duty bikes. Single plate clutches suit everyday passenger cars and light vehicles where simplicity, lower cost, and ease of maintenance are priorities, performing efficiently in standard urban and highway driving. Choosing between twin plate and single plate clutches depends on factors like vehicle power output, driving conditions, and desired responsiveness.

Pros and Cons of Twin Plate Clutches

Twin plate clutches offer improved torque capacity and better heat dissipation compared to single plate clutches, making them ideal for high-performance motorcycles and racing applications. Their main drawbacks include increased complexity, weight, and higher maintenance costs, which can be less suitable for everyday commuting. Enhanced clutch bite and smoother engagement characterize twin plate designs but may also lead to a slightly heavier clutch lever feel.

Pros and Cons of Single Plate Clutches

Single plate clutches offer simplicity, lighter weight, and easier maintenance, making them ideal for everyday vehicles with moderate power requirements. They provide smooth engagement and cost-effectiveness but may struggle with heat dissipation and wear under high torque or performance conditions. Your choice depends on balancing affordability and reliability against the need for handling higher power.

twin plate clutch vs single plate Infographic

libmatt.com

libmatt.com