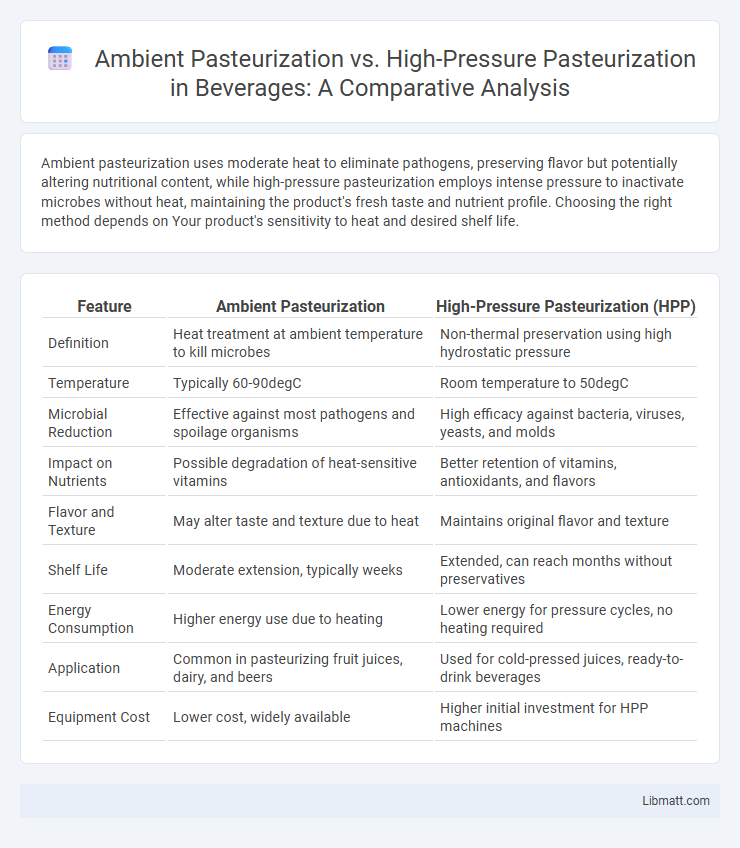

Ambient pasteurization uses moderate heat to eliminate pathogens, preserving flavor but potentially altering nutritional content, while high-pressure pasteurization employs intense pressure to inactivate microbes without heat, maintaining the product's fresh taste and nutrient profile. Choosing the right method depends on Your product's sensitivity to heat and desired shelf life.

Table of Comparison

| Feature | Ambient Pasteurization | High-Pressure Pasteurization (HPP) |

|---|---|---|

| Definition | Heat treatment at ambient temperature to kill microbes | Non-thermal preservation using high hydrostatic pressure |

| Temperature | Typically 60-90degC | Room temperature to 50degC |

| Microbial Reduction | Effective against most pathogens and spoilage organisms | High efficacy against bacteria, viruses, yeasts, and molds |

| Impact on Nutrients | Possible degradation of heat-sensitive vitamins | Better retention of vitamins, antioxidants, and flavors |

| Flavor and Texture | May alter taste and texture due to heat | Maintains original flavor and texture |

| Shelf Life | Moderate extension, typically weeks | Extended, can reach months without preservatives |

| Energy Consumption | Higher energy use due to heating | Lower energy for pressure cycles, no heating required |

| Application | Common in pasteurizing fruit juices, dairy, and beers | Used for cold-pressed juices, ready-to-drink beverages |

| Equipment Cost | Lower cost, widely available | Higher initial investment for HPP machines |

Introduction to Pasteurization Methods

Ambient pasteurization involves heating products to moderate temperatures around 60-75degC to eliminate pathogens and extend shelf life while preserving flavor and nutrients. High-pressure pasteurization (HPP) uses intense pressure, up to 600 MPa, to inactivate microbes without significant heat, maintaining the fresh characteristics of foods and beverages. Both methods ensure safety and quality but differ in their impact on texture, flavor, and nutrient retention.

What is Ambient Pasteurization?

Ambient pasteurization is a process that uses moderate heat to eliminate pathogens and spoilage microorganisms in food products without significantly altering their nutritional quality or flavor. Unlike high-pressure pasteurization, which relies on intense pressure to inactivate microbes, ambient pasteurization operates at temperatures typically between 60degC and 80degC. This method is suitable for extending shelf life while preserving the natural characteristics of fresh foods, making it an effective option for your food safety needs.

What is High-Pressure Pasteurization?

High-pressure pasteurization (HPP) is a non-thermal food preservation method that uses extreme pressure, typically between 400 and 600 megapascals, to inactivate pathogens and spoilage microorganisms without heat. Unlike ambient pasteurization, which relies on temperature elevation, HPP maintains the food's sensory and nutritional qualities by applying isostatic pressure uniformly across the product. This innovative technique enhances shelf life and safety while preserving texture, flavor, and vitamins often degraded by traditional heat pasteurization processes.

Key Differences Between Ambient and High-Pressure Pasteurization

Ambient pasteurization uses heat at temperatures typically between 60-85degC to inactivate microbes, while high-pressure pasteurization applies pressures up to 600 MPa without heat, preserving sensory and nutritional qualities. Ambient pasteurization often leads to nutrient loss and flavor changes, whereas high-pressure pasteurization maintains the product's freshness and bioactive compounds. The choice between these methods depends on the desired shelf life, product type, and quality retention.

Impact on Food Safety and Shelf Life

Ambient pasteurization relies on moderate heat treatment to reduce microbial load, effectively controlling spoilage bacteria but may have limited impact on pathogenic microorganisms, resulting in moderate shelf life extension. High-pressure pasteurization (HPP) employs intense pressure to inactivate pathogens and spoilage organisms without heat, significantly enhancing food safety and extending shelf life by preserving sensory and nutritional qualities. HPP-treated foods exhibit prolonged freshness, reduced risk of contamination, and improved retention of vitamins compared to those processed with ambient pasteurization.

Effects on Nutritional Value and Flavor

Ambient pasteurization, involving moderate heat exposure, can cause loss of heat-sensitive nutrients like vitamin C and slight flavor alterations through Maillard reactions. High-pressure pasteurization preserves more of the nutritional value, maintaining vitamins, antioxidants, and fresh flavors by avoiding elevated temperatures. Your choice between these methods impacts the retention of key nutrients and the authentic taste profile of the product.

Energy Efficiency and Environmental Considerations

Ambient pasteurization consumes significantly less energy compared to high-pressure pasteurization, primarily because it operates at lower temperatures and avoids the extensive energy demands of maintaining high pressure. High-pressure pasteurization requires substantial electricity to generate pressures up to 600 MPa, increasing operational costs and environmental impact due to higher carbon emissions. For Your production facility, choosing ambient pasteurization can reduce energy consumption and lower the carbon footprint, making it a more sustainable option for environmentally conscious food processing.

Cost Analysis: Ambient vs High-Pressure Pasteurization

Ambient pasteurization incurs lower initial equipment costs and reduced energy consumption, making it more cost-effective for small to mid-scale operations. High-pressure pasteurization demands significant capital investment and operational expenses due to advanced machinery and higher energy requirements. Despite higher costs, high-pressure pasteurization offers longer shelf life and better product quality, potentially offsetting expenses through improved market value and reduced spoilage.

Applications in Food and Beverage Industries

Ambient pasteurization is widely used in the food and beverage industries for products like milk, fruit juices, and canned goods, offering effective microbial reduction with minimal equipment cost. High-pressure pasteurization (HPP) is favored for cold-pressed juices, ready-to-eat meals, and deli meats, preserving nutritional quality and extending shelf life without heat damage. Your choice between these methods depends on the product type, desired shelf stability, and quality retention requirements.

Future Trends and Innovations in Pasteurization

Future trends in pasteurization emphasize enhancing product quality and extending shelf life through innovative techniques like high-pressure pasteurization (HPP), which preserves nutritional content better than ambient pasteurization. Advances in HPP technology include integrating intelligent sensors and automation systems for precise pressure control and real-time monitoring, leading to greater efficiency and safety. Emerging research explores combining HPP with other non-thermal methods, such as pulsed electric fields and ultraviolet light, to develop hybrid pasteurization processes with minimized thermal damage and improved microbial inactivation.

Ambient pasteurization vs high-pressure pasteurization Infographic

libmatt.com

libmatt.com