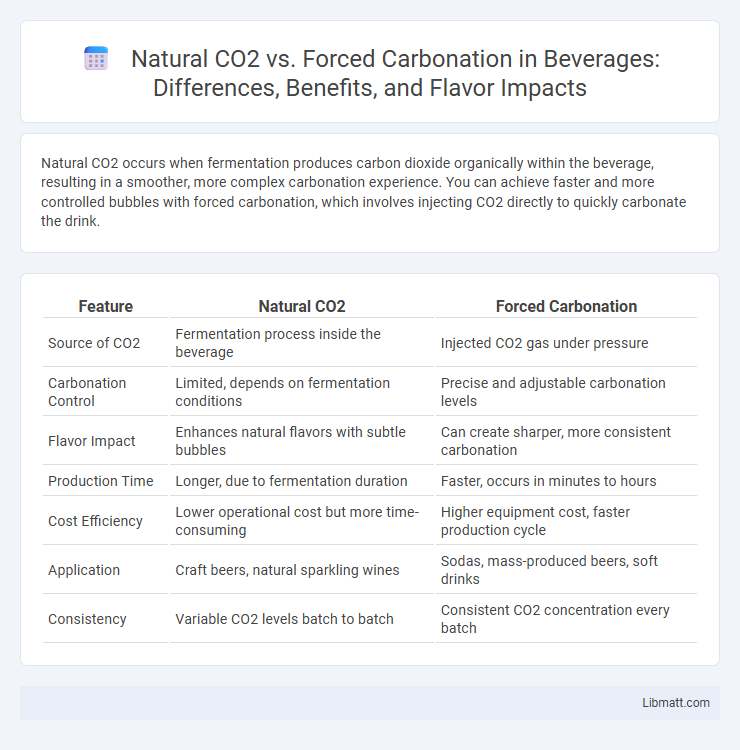

Natural CO2 occurs when fermentation produces carbon dioxide organically within the beverage, resulting in a smoother, more complex carbonation experience. You can achieve faster and more controlled bubbles with forced carbonation, which involves injecting CO2 directly to quickly carbonate the drink.

Table of Comparison

| Feature | Natural CO2 | Forced Carbonation |

|---|---|---|

| Source of CO2 | Fermentation process inside the beverage | Injected CO2 gas under pressure |

| Carbonation Control | Limited, depends on fermentation conditions | Precise and adjustable carbonation levels |

| Flavor Impact | Enhances natural flavors with subtle bubbles | Can create sharper, more consistent carbonation |

| Production Time | Longer, due to fermentation duration | Faster, occurs in minutes to hours |

| Cost Efficiency | Lower operational cost but more time-consuming | Higher equipment cost, faster production cycle |

| Application | Craft beers, natural sparkling wines | Sodas, mass-produced beers, soft drinks |

| Consistency | Variable CO2 levels batch to batch | Consistent CO2 concentration every batch |

Understanding Carbonation: Natural vs. Forced

Natural CO2 carbonation occurs through fermentation, where yeast produces carbon dioxide as a byproduct, creating a subtle, complex effervescence in beverages like beer and champagne. Forced carbonation involves injecting CO2 directly into the liquid under pressure, allowing precise control over carbonation levels and faster production times. Understanding these methods highlights how natural carbonation contributes to flavor depth, while forced carbonation ensures consistency and efficiency in the final product.

The Science Behind CO2 in Beverages

Natural CO2 in beverages results from fermentation, where yeast converts sugars into alcohol and carbon dioxide, creating a naturally carbonated drink with distinct flavors and a softer carbonation profile. Forced carbonation involves injecting CO2 gas directly into the beverage under controlled pressure, allowing precise adjustment of carbonation levels for consistency and sensory impact. The science behind CO2 in beverages centers on solubility, pressure, temperature, and the interaction of carbonic acid with taste receptors, influencing mouthfeel and perceived acidity.

How Natural Carbonation Occurs

Natural carbonation occurs through the fermentation process where yeast converts sugars into carbon dioxide and alcohol within the beverage. This carbon dioxide remains dissolved, creating bubbles without the need for external gas injection. Your understanding of natural carbonation highlights its reliance on biological activity rather than mechanical forcing methods.

Forced Carbonation: Methods and Techniques

Forced carbonation utilizes methods such as pressure injection, where CO2 gas is directly infused into the beverage under controlled pressure, accelerating carbonation. Techniques like counter-pressure filling maintain carbonation levels by minimizing CO2 loss during packaging. Equipment commonly used includes carbonation stones and inline carbonators, ensuring precise CO2 dissolution and consistent beverage quality.

Key Differences Between Natural and Forced Carbonation

Natural carbonation occurs through the fermentation process where yeast produces CO2, resulting in softer, more complex bubbles and richer flavor profiles. Forced carbonation involves injecting CO2 directly into the beverage under pressure, allowing for quicker carbonation with consistent bubble size and sharpness. The key differences lie in the carbonation method, timing, bubble texture, and resulting taste complexity.

Flavor Impacts: Natural vs. Forced CO2

Natural CO2 carbonation, produced through fermentation, creates finer bubbles that enhance the beer's mouthfeel and preserve delicate flavor nuances, leading to a smoother and more complex taste profile. Forced carbonation introduces CO2 under pressure, resulting in larger, sharper bubbles that can create a more aggressive carbonation feel and a slightly altered flavor perception. Understanding the difference helps you choose the carbonation method that best complements your beverage's intended flavor character.

Quality and Consistency in Carbonated Drinks

Natural CO2, generated through fermentation, imparts a purer and more nuanced carbonation profile that enhances the flavor complexity and mouthfeel of carbonated drinks. Forced carbonation using industrial CO2 allows for precise control over carbonation levels, ensuring consistent quality and carbonation intensity across batches. Brewers and beverage producers often balance natural CO2's artisanal qualities with the reliability and uniformity provided by forced carbonation for optimal product consistency.

Environmental Implications of Carbonation Methods

Natural CO2 carbonation, relying on organic fermentation processes, produces minimal environmental impact due to the absence of synthetic inputs and lower energy consumption compared to forced carbonation. Forced carbonation requires industrial CO2 capture and compression, which often depends on fossil fuel-derived sources, contributing to higher carbon footprints and potential greenhouse gas emissions. Evaluating the environmental implications reveals that natural carbonation offers a more sustainable approach by reducing reliance on artificial CO2 and lowering overall emissions associated with beverage production.

Which Method is Better for Homebrewers?

Natural CO2 carbonation offers homebrewers a traditional and cost-effective method by allowing yeast to ferment sugars in the bottle, creating authentic flavors and gentle carbonation while requiring patience during the conditioning phase. Forced carbonation provides precise control over carbonation levels and faster turnaround times through CO2 injection, making it ideal for brewers seeking consistency and efficiency. Choosing the better method depends on a homebrewer's priorities: natural carbonation enhances complexity and tradition, while forced carbonation suits speed and exact carbonation control.

Consumer Preferences and Market Trends

Consumer preferences increasingly favor natural CO2 carbonation for its perceived authenticity and smoother taste, aligning with growing demand for craft and artisanal beverages. Market trends highlight a rising segment of natural carbonation in premium and organic drinks, driven by health-conscious consumers seeking fewer additives. Your choice between natural CO2 and forced carbonation can influence product positioning, appealing to niche markets that prioritize traditional brewing methods and natural flavor profiles.

Natural CO2 vs forced carbonation Infographic

libmatt.com

libmatt.com