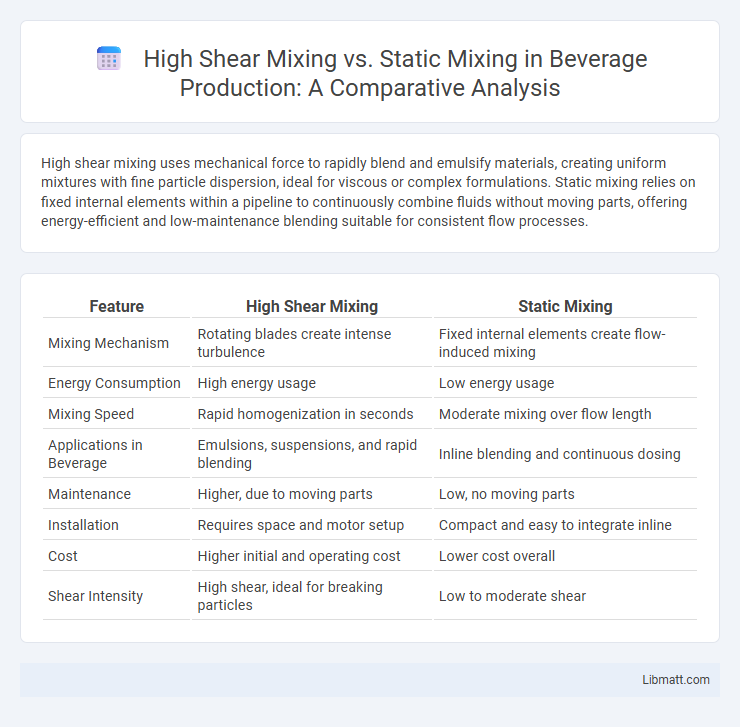

High shear mixing uses mechanical force to rapidly blend and emulsify materials, creating uniform mixtures with fine particle dispersion, ideal for viscous or complex formulations. Static mixing relies on fixed internal elements within a pipeline to continuously combine fluids without moving parts, offering energy-efficient and low-maintenance blending suitable for consistent flow processes.

Table of Comparison

| Feature | High Shear Mixing | Static Mixing |

|---|---|---|

| Mixing Mechanism | Rotating blades create intense turbulence | Fixed internal elements create flow-induced mixing |

| Energy Consumption | High energy usage | Low energy usage |

| Mixing Speed | Rapid homogenization in seconds | Moderate mixing over flow length |

| Applications in Beverage | Emulsions, suspensions, and rapid blending | Inline blending and continuous dosing |

| Maintenance | Higher, due to moving parts | Low, no moving parts |

| Installation | Requires space and motor setup | Compact and easy to integrate inline |

| Cost | Higher initial and operating cost | Lower cost overall |

| Shear Intensity | High shear, ideal for breaking particles | Low to moderate shear |

Introduction to High Shear and Static Mixing

High shear mixing involves intense mechanical agitation using rapidly rotating blades to create fine emulsions and dispersions, ideal for processes requiring uniform particle size reduction. Static mixing utilizes fixed internal elements within a pipeline to continuously blend fluids without moving parts, offering energy-efficient and low-maintenance operation. Your choice between high shear and static mixing depends on the desired mixing intensity, product viscosity, and process scale.

Principles of High Shear Mixing

High shear mixing operates by rapidly rotating blades or rotors that create intense turbulence and shear forces, leading to efficient dispersion, emulsification, and particle size reduction. This process enhances mass transfer and homogeneity in viscous or immiscible phases, making it ideal for complex formulations. You benefit from precise control over mixing intensity and time, ensuring consistent product quality in pharmaceuticals, cosmetics, and food industries.

Principles of Static Mixing

Static mixing relies on fixed internal elements within a pipe or channel that create turbulence and promote fluid blending without moving parts. The design of these elements generates controlled flow division and radial mixing, ensuring uniform distribution of components in laminar or turbulent flow regimes. Efficiency in static mixing stems from optimized geometry that enhances mass transfer and minimizes energy consumption compared to high shear mixing, which uses mechanical agitation.

Key Differences Between High Shear and Static Mixing

High shear mixing uses mechanical energy to rapidly blend materials through intense rotor-stator interactions, creating fine dispersions and emulsions, while static mixing relies on fixed internal elements within a pipe to continuously mix fluids as they flow without moving parts. High shear mixers excel in processes requiring emulsification, particle size reduction, and rapid homogenization, contrasting with static mixers that are preferred for low-energy, continuous blending in pipeline systems. The key differences center on energy input, scale of mixing, and equipment complexity, with high shear mixers offering aggressive, high-energy processing and static mixers delivering efficient, low-maintenance fluid mixing.

Applications of High Shear Mixing

High shear mixing is extensively used in applications requiring intense energy input to achieve uniform particle size reduction, such as emulsification, homogenization, and dispersion in pharmaceutical, cosmetic, and food industries. Its ability to quickly break down solids into liquids and create stable emulsions makes it ideal for producing creams, ointments, and sauces. High shear mixers are crucial in chemical processing for accelerating reactions and improving product consistency.

Applications of Static Mixing

Static mixing is widely applied in industries such as chemical processing, water treatment, and food production for blending fluids without moving parts. It is ideal for continuous mixing operations involving liquids, gases, or slurries, ensuring homogenous blending, heat transfer, and chemical reactions. Common uses include dispersing additives, neutralizing pH levels, and injecting chemicals in pipelines, offering energy efficiency and low maintenance.

Advantages of High Shear Mixing

High shear mixing offers superior particle size reduction and rapid emulsification compared to static mixing, ensuring uniform and stable product formulations. This process enhances reaction rates and improves heat transfer efficiency, making it ideal for complex chemical, pharmaceutical, and food applications. Your production benefits from its ability to handle high-viscosity materials and achieve consistent mixing results in shorter processing times.

Advantages of Static Mixing

Static mixing offers consistent and energy-efficient blending without moving parts, reducing maintenance costs and operational downtime. Its compact design allows seamless integration into pipelines, saving space and enhancing process flow control. You benefit from reliable mixing performance in continuous flow processes, making static mixers ideal for chemical, food, and wastewater treatment industries.

Choosing the Right Mixing Technology

High shear mixing delivers intense energy and rapid dispersion, ideal for emulsifying, homogenizing, and breaking down particles in viscous or complex fluids. Static mixing uses fixed internal elements to create turbulence and blend fluids efficiently without moving parts, perfect for continuous processes requiring low maintenance. Your choice depends on factors like fluid viscosity, mixing intensity, and system design, with high shear mixers preferred for aggressive blending and static mixers favored for energy efficiency and simplicity.

Conclusion: High Shear vs. Static Mixing

High shear mixing provides intense mechanical energy, enabling rapid dispersion and emulsification of challenging materials, which is crucial for processes requiring fine particle size reduction and uniform consistency. Static mixing relies on the flow of fluids through fixed elements to achieve blending without moving parts, making it energy-efficient and low-maintenance for continuous mixing applications. Choosing between high shear and static mixing depends on process requirements such as mixing intensity, product texture, and operational cost.

High shear mixing vs static mixing Infographic

libmatt.com

libmatt.com