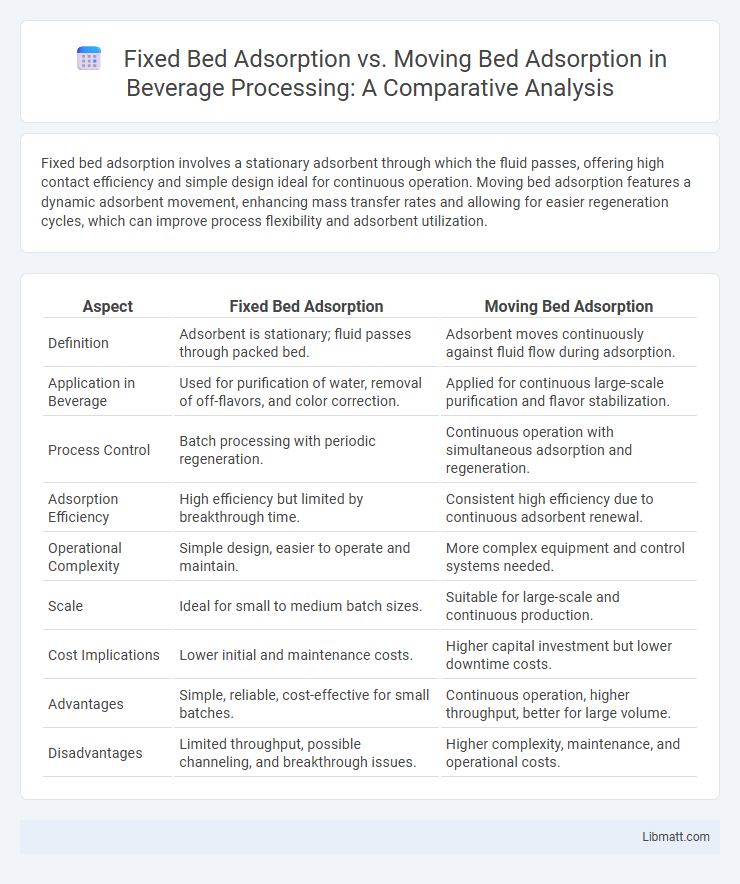

Fixed bed adsorption involves a stationary adsorbent through which the fluid passes, offering high contact efficiency and simple design ideal for continuous operation. Moving bed adsorption features a dynamic adsorbent movement, enhancing mass transfer rates and allowing for easier regeneration cycles, which can improve process flexibility and adsorbent utilization.

Table of Comparison

| Aspect | Fixed Bed Adsorption | Moving Bed Adsorption |

|---|---|---|

| Definition | Adsorbent is stationary; fluid passes through packed bed. | Adsorbent moves continuously against fluid flow during adsorption. |

| Application in Beverage | Used for purification of water, removal of off-flavors, and color correction. | Applied for continuous large-scale purification and flavor stabilization. |

| Process Control | Batch processing with periodic regeneration. | Continuous operation with simultaneous adsorption and regeneration. |

| Adsorption Efficiency | High efficiency but limited by breakthrough time. | Consistent high efficiency due to continuous adsorbent renewal. |

| Operational Complexity | Simple design, easier to operate and maintain. | More complex equipment and control systems needed. |

| Scale | Ideal for small to medium batch sizes. | Suitable for large-scale and continuous production. |

| Cost Implications | Lower initial and maintenance costs. | Higher capital investment but lower downtime costs. |

| Advantages | Simple, reliable, cost-effective for small batches. | Continuous operation, higher throughput, better for large volume. |

| Disadvantages | Limited throughput, possible channeling, and breakthrough issues. | Higher complexity, maintenance, and operational costs. |

Introduction to Adsorption Processes

Fixed bed adsorption employs a stationary adsorbent through which the fluid passes, allowing for efficient pollutant removal in applications like gas purification. Moving bed adsorption involves the continuous movement of the adsorbent material countercurrent to the fluid, enhancing regeneration and process control in large-scale operations. Both processes leverage surface phenomena for contaminant capture but differ in operational dynamics and industrial adaptability.

Overview of Fixed Bed Adsorption

Fixed bed adsorption involves passing a fluid stream through a stationary packed bed of adsorbent material, where target molecules adhere to the surface sites, enabling separation or purification processes. This method offers high adsorption capacity, simple operation, and easy regeneration but may suffer from channeling and mass transfer limitations as the bed saturates. Fixed bed adsorption is widely applied in gas purification, water treatment, and industrial solvent recovery due to its robustness and efficiency in continuous operations.

Fundamentals of Moving Bed Adsorption

Moving bed adsorption operates by continuously feeding the gas or liquid stream through a stationary adsorbent bed while simultaneously moving the adsorbent in the opposite direction, enhancing mass transfer and adsorption efficiency compared to fixed bed systems where the adsorbent is stationary. The moving bed configuration allows for continuous separation and regeneration processes, improving operational throughput and reducing downtime. This method is particularly advantageous for handling large scale flows with variable concentrations, optimizing adsorption capacity and selectivity through controlled adsorbent movement and contact time.

Key Differences Between Fixed and Moving Bed Adsorption

Fixed bed adsorption involves a stationary adsorbent where the fluid passes through a packed column, allowing for high adsorption efficiency but limited continuous operation. Moving bed adsorption features a continuous movement of the adsorbent material, enhancing regeneration and reducing downtime while maintaining steady-state conditions. Your choice between fixed and moving bed systems depends on factors such as process scale, adsorption capacity, and operational continuity requirements.

Efficiency and Performance Comparison

Fixed bed adsorption systems typically offer higher adsorption efficiency due to longer contact time between the adsorbent and adsorbate, ensuring thorough contaminant removal. In contrast, moving bed adsorption provides improved performance in continuous operation and better handling of variable feed concentrations, enhancing overall process stability. Fixed beds excel in high-purity applications, whereas moving beds optimize throughput and reduce pressure drop, making them favorable for large-scale industrial processes.

Operational Costs and Energy Consumption

Fixed bed adsorption systems have lower operational costs due to simpler design and less complex regeneration processes but often face higher energy consumption during the regeneration phase because of prolonged heating requirements. Moving bed adsorption units typically incur higher operational expenses from the need for mechanical components and continuous solids handling, yet they achieve reduced energy consumption by enabling more efficient heat integration and shorter regeneration cycles. Energy-intensive pressure drop management in fixed beds contrasts with better flow distribution and energy savings in moving beds, impacting overall process efficiency and cost-effectiveness.

Applications in Water and Air Treatment

Fixed bed adsorption is widely used in water treatment for the removal of contaminants such as heavy metals and organic pollutants due to its high contact efficiency and straightforward operation. Moving bed adsorption, commonly applied in air purification systems, allows continuous regeneration of the adsorbent, enhancing the removal of volatile organic compounds (VOCs) and airborne toxins. Your choice between these technologies depends on factors like the specific contaminants, desired treatment capacity, and operational maintenance preferences.

Regeneration and Adsorbent Utilization

Fixed bed adsorption typically involves periodic regeneration cycles where the adsorbent is offline during desorption, resulting in lower adsorbent utilization. Moving bed adsorption allows continuous regeneration as the adsorbent moves between adsorption and regeneration zones, enhancing overall adsorbent efficiency. Your choice depends on whether constant operation or simpler system design is prioritized for optimal adsorbent utilization.

Advantages and Limitations of Each Method

Fixed bed adsorption offers high adsorption efficiency and simple operation, making it ideal for treating low-flow or continuous streams, but it faces challenges with mass transfer limitations and difficulty in regeneration due to channeling and pressure drop issues. Moving bed adsorption allows for continuous regeneration and better handling of high-throughput processes, reducing downtime and improving overall system productivity, though it requires more complex equipment and maintenance. Your choice between these methods depends on the specific process demands, capacity requirements, and operational flexibility.

Future Trends and Innovations in Adsorption Technologies

Future trends in fixed bed adsorption emphasize enhanced material development such as advanced zeolites and metal-organic frameworks (MOFs) to increase capacity and selectivity, while innovations in moving bed adsorption focus on continuous processing and energy efficiency improvements. Researchers are exploring hybrid systems combining fixed and moving beds to optimize adsorption-desorption cycles, improving overall system sustainability and throughput. Your next-generation adsorption system can benefit from these advancements, offering increased performance in gas separation and purification applications.

Fixed bed adsorption vs moving bed adsorption Infographic

libmatt.com

libmatt.com