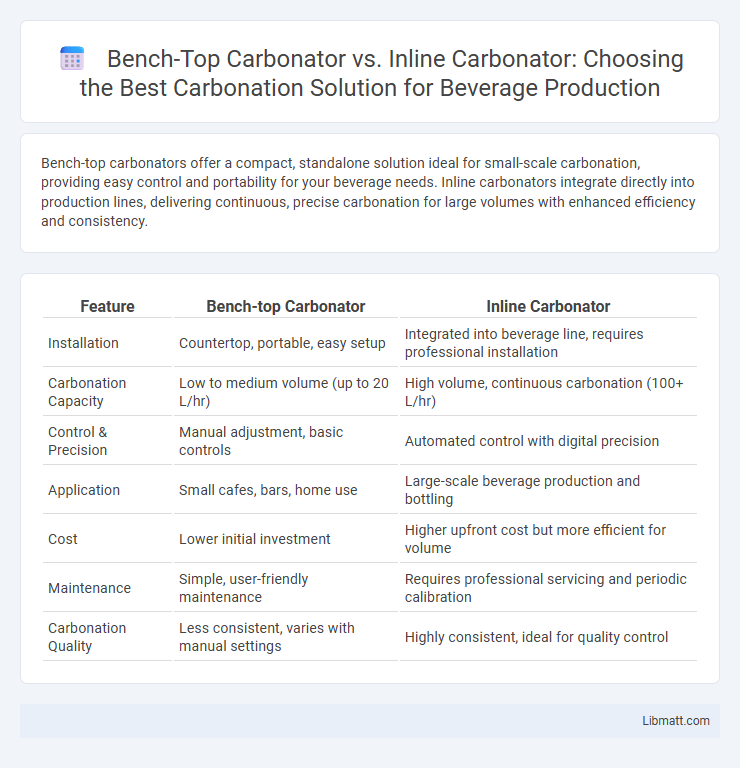

Bench-top carbonators offer a compact, standalone solution ideal for small-scale carbonation, providing easy control and portability for your beverage needs. Inline carbonators integrate directly into production lines, delivering continuous, precise carbonation for large volumes with enhanced efficiency and consistency.

Table of Comparison

| Feature | Bench-top Carbonator | Inline Carbonator |

|---|---|---|

| Installation | Countertop, portable, easy setup | Integrated into beverage line, requires professional installation |

| Carbonation Capacity | Low to medium volume (up to 20 L/hr) | High volume, continuous carbonation (100+ L/hr) |

| Control & Precision | Manual adjustment, basic controls | Automated control with digital precision |

| Application | Small cafes, bars, home use | Large-scale beverage production and bottling |

| Cost | Lower initial investment | Higher upfront cost but more efficient for volume |

| Maintenance | Simple, user-friendly maintenance | Requires professional servicing and periodic calibration |

| Carbonation Quality | Less consistent, varies with manual settings | Highly consistent, ideal for quality control |

Overview of Bench-top and Inline Carbonators

Bench-top carbonators are compact, portable devices designed for personal or small-scale use, efficiently carbonating beverages directly at the point of consumption. Inline carbonators integrate seamlessly into larger production lines or beverage dispensing systems, ensuring continuous carbonation with precise control over CO2 levels. Your choice between bench-top and inline carbonators depends on the scale of carbonation needs and the desired level of automation and consistency.

How Bench-top Carbonators Work

Bench-top carbonators infuse carbonation by forcing CO2 into water within a sealed container using a built-in CO2 cartridge or external gas source. These compact devices rely on pressure and agitation to dissolve gas effectively, creating fizzy water on demand. Designed for small-scale or home use, bench-top models offer convenience and portability without extensive plumbing or installation requirements.

How Inline Carbonators Work

Inline carbonators inject CO2 directly into the water supply through a pressurized system, ensuring consistent carbonation levels for each pour. Your beverage is carbonated instantly as water flows through the system, offering precise control over carbonation strength and reducing waste. This method is ideal for commercial setups requiring efficient, high-volume carbonation without the need for separate mixing containers.

Key Differences Between Bench-top and Inline Carbonators

Bench-top carbonators are compact, portable devices designed for small-scale carbonation, ideal for home use or small batches, while inline carbonators integrate directly into beverage production lines, providing continuous and large-volume carbonation. Inline carbonators offer precise control over carbonation levels with automated adjustments, enhancing consistency in commercial settings, whereas bench-top models require manual operation and are limited in output capacity. Your choice depends on scale and convenience, with bench-top units suited for flexibility and inline systems optimized for high-efficiency production.

Advantages of Bench-top Carbonators

Bench-top carbonators offer superior portability and easy installation, making them ideal for small businesses or home use where space is limited. These devices allow precise control over carbonation levels, enhancing the quality and customization of your beverages. You benefit from lower upfront costs and minimal maintenance compared to inline carbonators, ensuring a cost-effective and flexible solution.

Advantages of Inline Carbonators

Inline carbonators offer precise carbonation control by integrating directly with your beverage system, ensuring consistent CO2 levels and superior taste quality. They save valuable counter space compared to bulky bench-top models, making them ideal for high-volume or commercial applications. Your operations benefit from increased efficiency and reduced maintenance through continuous carbonation without manual intervention.

Applications for Bench-top Carbonators

Bench-top carbonators are ideal for small-scale beverage production, craft brewing, and laboratory testing where precise control over carbonation levels is essential. They are frequently used in restaurants, bars, and home brewing setups to carbonate individual batches quickly without the need for extensive piping or equipment. These carbonators offer flexibility in applications requiring low to moderate volume carbonation with easy portability and straightforward operation.

Applications for Inline Carbonators

Inline carbonators are commonly used in large-scale beverage production facilities for continuous carbonation of soft drinks, sparkling water, and beer, ensuring consistent CO2 levels throughout the process. They support high-volume operations by integrating directly into production lines, enhancing efficiency and reducing the need for manual adjustments. Inline carbonators are ideal for breweries, bottling plants, and automated beverage dispensing systems where precise control and scalability are critical.

Factors to Consider When Choosing a Carbonator

When choosing between a bench-top carbonator and an inline carbonator, consider factors such as installation space, carbonation volume, and maintenance requirements. Bench-top carbonators are ideal for smaller-scale or portable use, offering easy setup and control, while inline carbonators suit high-volume production with seamless integration into existing systems. Evaluate your operational capacity and frequency of use to ensure your choice aligns with your carbonation efficiency and workflow needs.

Bench-top vs Inline Carbonator: Which is Right for You?

Bench-top carbonators offer portability and easy installation, ideal for small-scale or home use where space and convenience matter most. Inline carbonators integrate directly into existing beverage lines, providing consistent carbonation for commercial operations requiring high volume and efficiency. Choosing between bench-top and inline carbonators depends on your production scale, available space, and desired control over carbonation levels.

Bench-top carbonator vs inline carbonator Infographic

libmatt.com

libmatt.com