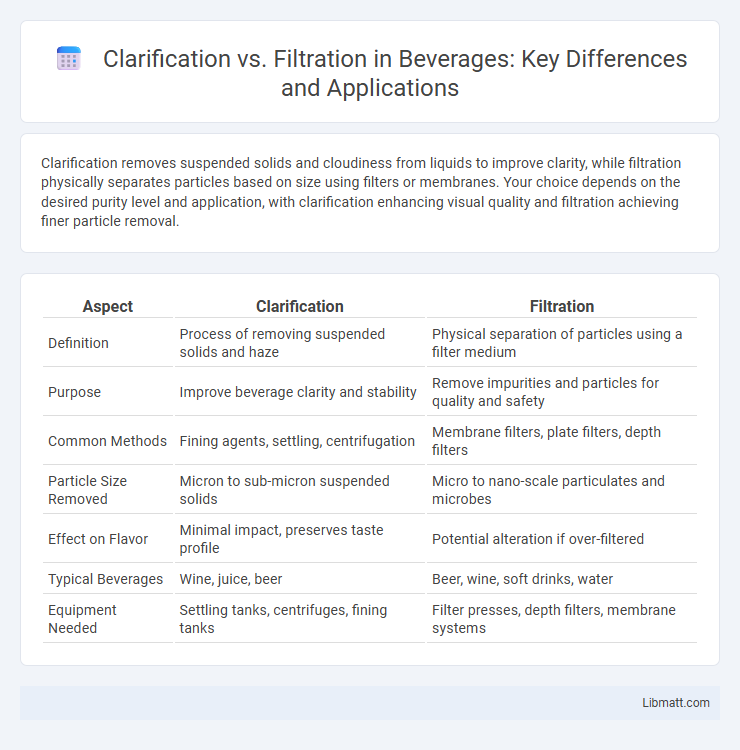

Clarification removes suspended solids and cloudiness from liquids to improve clarity, while filtration physically separates particles based on size using filters or membranes. Your choice depends on the desired purity level and application, with clarification enhancing visual quality and filtration achieving finer particle removal.

Table of Comparison

| Aspect | Clarification | Filtration |

|---|---|---|

| Definition | Process of removing suspended solids and haze | Physical separation of particles using a filter medium |

| Purpose | Improve beverage clarity and stability | Remove impurities and particles for quality and safety |

| Common Methods | Fining agents, settling, centrifugation | Membrane filters, plate filters, depth filters |

| Particle Size Removed | Micron to sub-micron suspended solids | Micro to nano-scale particulates and microbes |

| Effect on Flavor | Minimal impact, preserves taste profile | Potential alteration if over-filtered |

| Typical Beverages | Wine, juice, beer | Beer, wine, soft drinks, water |

| Equipment Needed | Settling tanks, centrifuges, fining tanks | Filter presses, depth filters, membrane systems |

Introduction to Clarification and Filtration

Clarification and filtration are essential processes in water and liquid treatment, targeting the removal of suspended solids and impurities to ensure clarity and purity. Clarification typically involves settling or coagulation techniques to separate larger particles, while filtration passes the liquid through media to capture finer contaminants. Understanding these processes helps optimize your system's efficiency and improve overall water quality.

Definitions: Clarification and Filtration Explained

Clarification involves the removal of suspended solids and impurities from liquids through processes like sedimentation or centrifugation to achieve a clearer solution. Filtration, on the other hand, is the physical separation of particles by passing the liquid through a filter medium that traps unwanted materials. Understanding the distinctions between clarification and filtration ensures your liquid treatment process is optimized for desired purity and clarity outcomes.

Key Differences Between Clarification and Filtration

Clarification primarily removes suspended solids and cloudiness from liquids through sedimentation or flocculation, while filtration physically traps particles using a porous medium like a filter paper or membrane. Filtration typically offers finer particle removal compared to clarification, targeting particles as small as microns or even nanometers. Understanding these key differences helps you choose the right process for achieving desired liquid purity levels based on particle size and removal efficiency.

Principles Underlying Each Process

Clarification relies on gravity and particle aggregation to remove suspended solids, using flocculation and sedimentation principles to separate impurities from liquids. Filtration operates by passing the liquid through a porous medium or membrane that physically traps particles based on size exclusion or charge interactions. Your choice of process depends on the nature of contaminants and the desired purity level, with clarification suited for larger particles and filtration effective against finer impurities.

Types of Clarification Methods

Clarification methods include gravitational settling, flotation, and sedimentation, each designed to remove suspended solids from liquids effectively. Coagulation and flocculation are chemical processes that aid in the aggregation of particles, improving the efficiency of clarification. Your choice of clarification technique depends on the specific characteristics of the liquid and the contaminants being treated.

Types of Filtration Techniques

Filtration techniques are essential in clarifying liquids by removing suspended solids and impurities through mechanical or chemical means. Common types include gravity filtration, vacuum filtration, and membrane filtration, each designed to handle specific particle sizes and flow rates for optimal purity. Your choice of filtration depends on the application's requirements, such as the degree of filtration needed and the characteristics of the liquid being processed.

Common Applications in Industries

Clarification is extensively used in the beverage industry to remove suspended solids from liquids, enhancing product clarity and stability, while filtration is critical in pharmaceuticals to ensure sterility by trapping microorganisms and particulates. In wastewater treatment plants, clarification separates sludge from water, enabling efficient processing, whereas filtration further polishes effluent by removing fine particles. Food processing relies on both methods: clarification for juice and oil purity, and filtration for safeguarding food safety by eliminating contaminants.

Advantages and Limitations of Each Process

Clarification offers the advantage of removing suspended solids and improving liquid clarity quickly, making it ideal for beverages and wastewater treatment; however, it may not eliminate all fine particles or dissolved substances. Filtration provides superior removal of fine particulates and microorganisms using various filter media, enhancing product purity and safety though it can be costlier and slower with potential filter clogging. Your choice depends on the required clarity level, cost constraints, and the nature of the liquid to be treated.

Factors Influencing Process Selection

Factors influencing the selection between clarification and filtration include the nature of the suspended particles, desired final product clarity, and processing speed requirements. Clarification is preferred for larger, easily settleable solids and quicker separation, while filtration suits finer particles needing thorough removal for quality consistency. Your choice depends on particle size distribution, operational costs, and the necessity for downstream processing compatibility.

Summary: Choosing Between Clarification and Filtration

Clarification and filtration both improve liquid quality but serve different purposes; clarification removes suspended solids to enhance clarity, while filtration targets smaller particles or contaminants to ensure purity. Your choice depends on the specific impurities present and the desired outcome for your liquid, such as clarity versus sterility. Understanding these distinctions helps optimize processing efficiency and product quality.

Clarification vs filtration Infographic

libmatt.com

libmatt.com