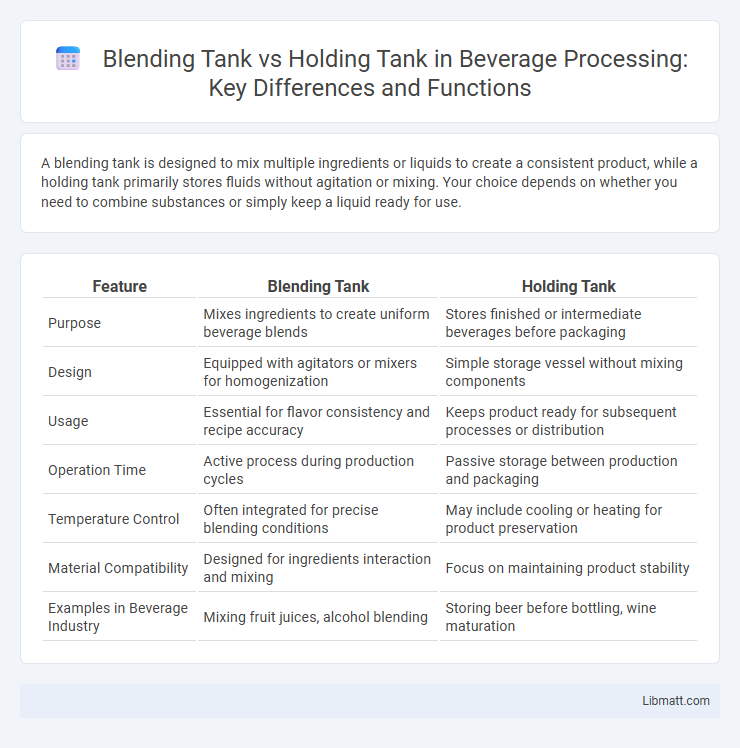

A blending tank is designed to mix multiple ingredients or liquids to create a consistent product, while a holding tank primarily stores fluids without agitation or mixing. Your choice depends on whether you need to combine substances or simply keep a liquid ready for use.

Table of Comparison

| Feature | Blending Tank | Holding Tank |

|---|---|---|

| Purpose | Mixes ingredients to create uniform beverage blends | Stores finished or intermediate beverages before packaging |

| Design | Equipped with agitators or mixers for homogenization | Simple storage vessel without mixing components |

| Usage | Essential for flavor consistency and recipe accuracy | Keeps product ready for subsequent processes or distribution |

| Operation Time | Active process during production cycles | Passive storage between production and packaging |

| Temperature Control | Often integrated for precise blending conditions | May include cooling or heating for product preservation |

| Material Compatibility | Designed for ingredients interaction and mixing | Focus on maintaining product stability |

| Examples in Beverage Industry | Mixing fruit juices, alcohol blending | Storing beer before bottling, wine maturation |

Introduction to Blending Tanks and Holding Tanks

Blending tanks are specialized vessels designed to mix multiple ingredients evenly, ensuring consistent product quality in industries like pharmaceuticals, food processing, and chemicals. Holding tanks serve as temporary storage containers that maintain the integrity of liquids before processing or packaging without any mixing function. Both tanks are essential in production workflows, with blending tanks focusing on homogenization and holding tanks prioritizing storage and preservation.

Key Definitions: Blending Tank vs Holding Tank

A blending tank is designed to mix multiple ingredients to achieve a uniform solution or product, often equipped with agitators or mixers for optimal consistency. A holding tank serves as a storage vessel for raw materials, intermediate products, or finished goods, maintaining contents without altering their composition. While blending tanks focus on homogenization and reaction control, holding tanks prioritize temporary containment and preservation of liquids or mixtures.

Primary Functions and Purposes

A blending tank is designed to combine different liquids or ingredients uniformly to achieve a specific mixture or chemical composition, essential in industries like pharmaceuticals and food processing. A holding tank primarily serves as a temporary storage vessel to maintain the integrity and stability of liquids before further processing or transfer. Your choice depends on whether you need to mix components thoroughly or simply store fluids safely.

Design Differences and Construction

Blending tanks are specifically designed with internal agitators and mixers to ensure uniformity and homogeneity of liquid contents, featuring materials resistant to chemical reactions and precise temperature control elements. Holding tanks prioritize storage capacity and structural integrity, often constructed with thicker walls and fewer internal components to safely contain fluids without agitation. Your choice between these tanks depends on the need for mixing capabilities versus simple storage requirements, influencing design complexity and construction materials.

Operational Processes Involved

Blending tanks facilitate the thorough mixing of multiple ingredients through controlled agitation and temperature regulation, ensuring homogeneity in your product before further processing. Holding tanks serve as temporary storage vessels that maintain the quality and stability of liquids without active mixing, primarily relying on gentle agitation or static conditions to prevent sedimentation. Efficient operational processes differentiate both tanks, with blending tanks focusing on dynamic mixing protocols and holding tanks emphasizing preservation and controlled storage environments.

Typical Applications in Industry

Blending tanks are commonly used in industries such as pharmaceuticals, cosmetics, and food processing for mixing ingredients to achieve a uniform product. Holding tanks serve primarily in chemical, water treatment, and oil refining sectors, storing liquids temporarily before further processing or distribution. Your choice depends on whether you need active mixing or simply passive storage.

Advantages of Blending Tanks

Blending tanks offer precise control over the mixing process, ensuring consistent product quality by thoroughly combining ingredients. These tanks enhance efficiency by enabling uniform dispersion of additives, reducing processing time, and minimizing waste. Your operations benefit from improved flexibility as blending tanks can accommodate various formulations and volumes, unlike holding tanks designed primarily for simple storage.

Benefits of Holding Tanks

Holding tanks offer significant benefits such as preventing contamination by securely storing liquids until proper disposal or treatment, ensuring environmental compliance and safety. They provide flexible storage capacity that adapts to fluctuating volumes, reducing overflow risks and operational downtime. Your facility can improve waste management efficiency and meet regulatory standards by incorporating holding tanks into its system.

Factors to Consider When Choosing Between Blending and Holding Tanks

Choosing between blending tanks and holding tanks depends on factors like the nature of the fluid, mixing requirements, and storage duration. Blending tanks are optimized for thorough mixing of ingredients, ensuring product consistency, while holding tanks prioritize storage without agitation. Your decision should consider process objectives, tank design, and operational needs to select the most efficient solution.

Conclusion: Selecting the Right Tank for Your Needs

Selecting the right tank depends on the specific application requirements; blending tanks are ideal for mixing and homogenizing liquids, ensuring consistent product quality in industries like pharmaceuticals and food processing. Holding tanks serve primarily as storage vessels to maintain liquid containment without agitation, suitable for temporary storage or buffering in chemical and wastewater treatment. Understanding the operational purpose, mixing needs, and process integration guides the optimal choice between blending tanks and holding tanks.

Blending tank vs holding tank Infographic

libmatt.com

libmatt.com