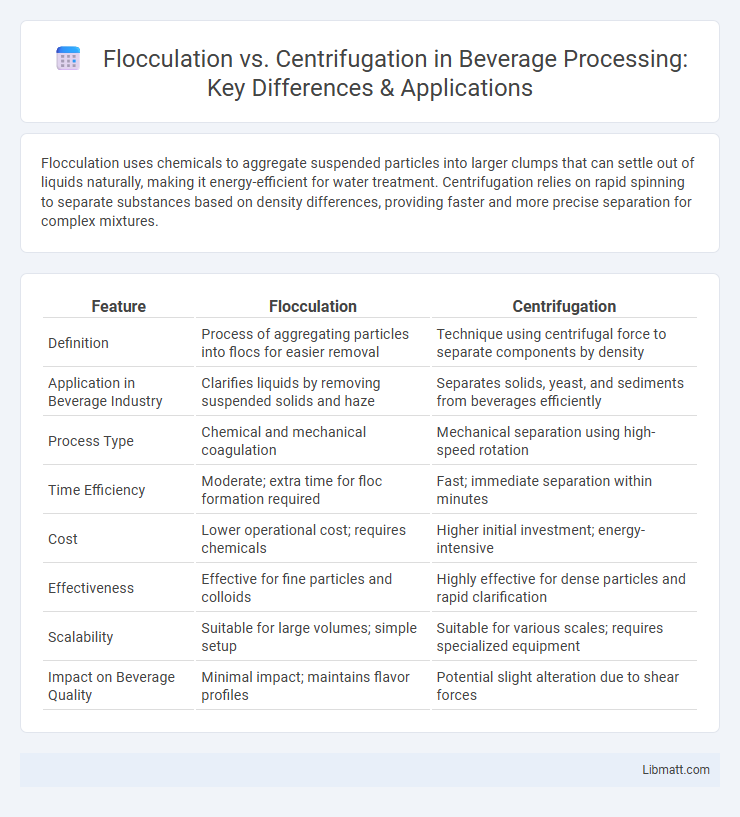

Flocculation uses chemicals to aggregate suspended particles into larger clumps that can settle out of liquids naturally, making it energy-efficient for water treatment. Centrifugation relies on rapid spinning to separate substances based on density differences, providing faster and more precise separation for complex mixtures.

Table of Comparison

| Feature | Flocculation | Centrifugation |

|---|---|---|

| Definition | Process of aggregating particles into flocs for easier removal | Technique using centrifugal force to separate components by density |

| Application in Beverage Industry | Clarifies liquids by removing suspended solids and haze | Separates solids, yeast, and sediments from beverages efficiently |

| Process Type | Chemical and mechanical coagulation | Mechanical separation using high-speed rotation |

| Time Efficiency | Moderate; extra time for floc formation required | Fast; immediate separation within minutes |

| Cost | Lower operational cost; requires chemicals | Higher initial investment; energy-intensive |

| Effectiveness | Effective for fine particles and colloids | Highly effective for dense particles and rapid clarification |

| Scalability | Suitable for large volumes; simple setup | Suitable for various scales; requires specialized equipment |

| Impact on Beverage Quality | Minimal impact; maintains flavor profiles | Potential slight alteration due to shear forces |

Introduction to Flocculation and Centrifugation

Flocculation is a water treatment process that aggregates fine particles into larger clumps, enhancing sedimentation and filtration efficiency. Centrifugation separates components based on density differences by applying centrifugal force, rapidly isolating solids from liquids. Both methods are essential in industrial and environmental applications for effective solid-liquid separation.

Definitions and Core Principles

Flocculation is a water treatment process that aggregates suspended particles into larger clusters called flocs, enhancing sedimentation or filtration efficiency, primarily driven by the addition of chemical flocculants that neutralize particle charges. Centrifugation separates mixtures through rapid spinning, utilizing centrifugal force to stratify components based on their density differences, which efficiently isolates solids from liquids without chemical additives. Both methods are essential in industrial and environmental applications, where flocculation optimizes coagulation and sedimentation, while centrifugation provides precise phase separation in complex mixtures.

Mechanisms of Action

Flocculation involves the aggregation of suspended particles into larger clusters through the addition of flocculants, which neutralize charge and promote particle binding, facilitating sedimentation. Centrifugation separates particles based on density differences by rapidly spinning the sample, creating centrifugal force that drives denser particles outward and lighter particles inward. Understanding these mechanisms allows you to select the most efficient method for separating solids from liquids in wastewater treatment, laboratory analysis, or industrial processes.

Key Differences Between Flocculation and Centrifugation

Flocculation involves aggregating fine particles into larger clumps called flocs using chemical agents, facilitating easier sedimentation in water treatment processes. Centrifugation separates particles from liquids by applying centrifugal force at high speeds, effectively isolating solids based on density differences. Understanding these key differences helps you choose the appropriate method for efficient particle removal in various industrial and environmental applications.

Advantages of Flocculation

Flocculation offers distinct advantages such as lower energy consumption compared to centrifugation, making it an economically viable method for large-scale water treatment. This technique enhances particle aggregation, improving sedimentation efficiency and reducing the need for expensive mechanical separation. Flocculation also allows for effective removal of suspended solids and contaminants in diverse industrial applications, including wastewater management and drinking water purification.

Advantages of Centrifugation

Centrifugation offers rapid and efficient separation of particles based on density differences, making it ideal for processing heterogeneous mixtures. It provides high precision in isolating fine particles or cells, which flocculation may not achieve due to reliance on chemical coagulants. Your laboratory or industrial processes benefit from centrifugation's scalability and reproducibility, ensuring consistent results in applications like blood separation or wastewater treatment.

Limitations and Challenges

Flocculation faces limitations such as inconsistent aggregate size, sensitivity to pH and chemical dosages, and challenges in treating high turbidity waters, which can reduce separation efficiency. Centrifugation encounters challenges like high energy consumption, equipment costs, and limited effectiveness with very fine or low-density particles. Your choice depends on balancing operational costs with the specific characteristics of the water or slurry being treated.

Typical Applications in Industry

Flocculation is widely used in wastewater treatment plants to aggregate suspended solids for easier removal, improving water clarity and quality. Centrifugation finds typical applications in the food industry for separating cream from milk, in pharmaceuticals for isolating biological components, and in chemical manufacturing to separate solid-liquid mixtures efficiently. Both methods enhance process efficiency by targeting different physical properties, with flocculation focusing on particle aggregation and centrifugation exploiting density differences.

Environmental and Economic Considerations

Flocculation uses natural or chemical agents to aggregate suspended particles, reducing the need for high energy consumption and minimizing environmental impact compared to centrifugation, which requires significant electricity for rapid spinning. Your choice between flocculation and centrifugation should consider operational costs, as flocculation is often more cost-effective for large volumes while centrifugation provides faster separation suitable for smaller-scale or high-value processes. Waste produced during flocculation may require additional treatment, influencing environmental sustainability, whereas centrifugation generates concentrated sludge that demands careful disposal and can increase overall expenses.

Choosing the Right Method for Your Needs

Flocculation is ideal for treating large volumes of liquid with suspended particles by aggregating contaminants into larger clumps for easier removal, often used in water treatment and waste management. Centrifugation provides rapid and efficient separation based on density differences, suitable for laboratory analysis and processing smaller sample sizes with precision. Understanding your specific needs for efficiency, volume, and purity will help you select between flocculation's cost-effective scalability and centrifugation's speed and accuracy.

Flocculation vs centrifugation Infographic

libmatt.com

libmatt.com