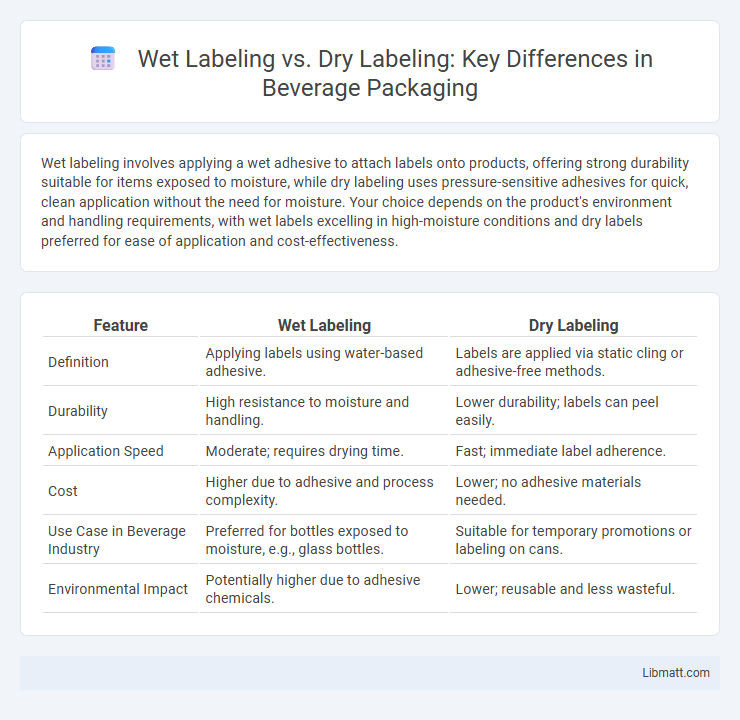

Wet labeling involves applying a wet adhesive to attach labels onto products, offering strong durability suitable for items exposed to moisture, while dry labeling uses pressure-sensitive adhesives for quick, clean application without the need for moisture. Your choice depends on the product's environment and handling requirements, with wet labels excelling in high-moisture conditions and dry labels preferred for ease of application and cost-effectiveness.

Table of Comparison

| Feature | Wet Labeling | Dry Labeling |

|---|---|---|

| Definition | Applying labels using water-based adhesive. | Labels are applied via static cling or adhesive-free methods. |

| Durability | High resistance to moisture and handling. | Lower durability; labels can peel easily. |

| Application Speed | Moderate; requires drying time. | Fast; immediate label adherence. |

| Cost | Higher due to adhesive and process complexity. | Lower; no adhesive materials needed. |

| Use Case in Beverage Industry | Preferred for bottles exposed to moisture, e.g., glass bottles. | Suitable for temporary promotions or labeling on cans. |

| Environmental Impact | Potentially higher due to adhesive chemicals. | Lower; reusable and less wasteful. |

Introduction to Wet Labeling and Dry Labeling

Wet labeling involves applying adhesive labels directly onto product surfaces, ensuring strong adhesion and vibrant graphics ideal for glass, plastic, or metal containers. Dry labeling uses pressure-sensitive or shrink sleeves, allowing labels to be applied without moisture, which is perfect for delicate or uneven surfaces and enables quick, efficient application lines. Your choice between wet or dry labeling impacts the durability, appearance, and production speed, depending on the product material and environmental conditions.

Key Differences Between Wet and Dry Labeling

Wet labeling involves applying pre-printed adhesive labels onto products using water-based glues, ensuring strong adhesion and vibrant label quality, commonly used for bottles and jars. Dry labeling employs direct printing or heat-sensitive films that bond to the product surface without moisture, offering faster application and suitability for irregular shapes or materials sensitive to water. Key differences include the adhesive method, application speed, compatibility with surfaces, and label durability under varying environmental conditions.

Advantages of Wet Labeling

Wet labeling offers superior adhesion on a wide range of surfaces, including curved, textured, or irregular containers, ensuring labels stay intact even in moist or refrigerated environments. This method allows for high-quality, vibrant labels with excellent durability and resistance to abrasion, moisture, and chemicals, enhancing your product's shelf appeal and longevity. With the flexibility to apply labels at various production speeds and conditions, wet labeling is ideal for industries requiring reliable and visually appealing packaging solutions.

Advantages of Dry Labeling

Dry labeling offers advantages such as enhanced durability and resistance to moisture, abrasion, and chemicals, which makes the labels more suitable for harsh environments. The process reduces production time and cost since it does not require drying or curing, increasing manufacturing efficiency. Furthermore, dry labels provide a cleaner, more precise application with minimal waste compared to wet labeling methods.

Common Applications for Wet Labeling

Wet labeling is commonly used in industries requiring strong adhesion on uneven or textured surfaces, such as glass bottles in the beverage and cosmetics sectors. This method excels in applications needing waterproof and durable labels that remain intact during handling and washing processes. Food packaging and pharmaceutical products also benefit from wet labeling due to its reliability in maintaining label integrity in humid or refrigerated environments.

Common Applications for Dry Labeling

Dry labeling is commonly used for applications that require quick, efficient labeling without the use of adhesives or moisture, such as on electronic devices, glass bottles, and metal containers. This method is favored in industries like electronics, cosmetics, and beverage packaging where precision and clean aesthetics are essential. Its ability to minimize mess and downtime makes it ideal for high-speed production lines and recyclable packaging solutions.

Cost Comparison: Wet vs Dry Labeling

Wet labeling generally incurs higher costs due to the use of adhesives, specialized equipment, and longer application times, impacting your overall production budget. Dry labeling, using pressure-sensitive materials, offers a more cost-effective alternative with faster application and reduced waste, making it ideal for high-volume runs. Choosing between the two depends on your budget constraints, as dry labeling typically minimizes expenses while maintaining labeling quality.

Speed and Efficiency: Which Method Wins?

Dry labeling offers superior speed and efficiency compared to wet labeling due to its adhesive backing, allowing instant application without drying time. Wet labeling requires the application of glue or water-based adhesives, increasing production time and the likelihood of errors or misalignments. Industries prioritizing rapid packaging processes, such as food and beverage, often choose dry labeling to streamline operations and reduce labor costs.

Environmental Impact of Wet and Dry Labeling

Wet labeling typically involves adhesives and water-based processes, which can increase energy consumption and water usage, contributing to a higher environmental footprint. Dry labeling, often using pressure-sensitive materials, generally reduces water waste and VOC emissions, making it a more eco-friendly option. Choosing dry labeling can help your company minimize waste and support sustainable packaging initiatives.

Choosing the Right Labeling Method for Your Business

Choosing the right labeling method for your business depends on product type, packaging material, and production volume. Wet labeling involves applying adhesive labels, ideal for flexible and curved surfaces, while dry labeling uses pressure-sensitive materials that offer easy application and removal. Understanding these differences ensures your products have durable, visually appealing labels that align with your branding and operational needs.

Wet labeling vs dry labeling Infographic

libmatt.com

libmatt.com