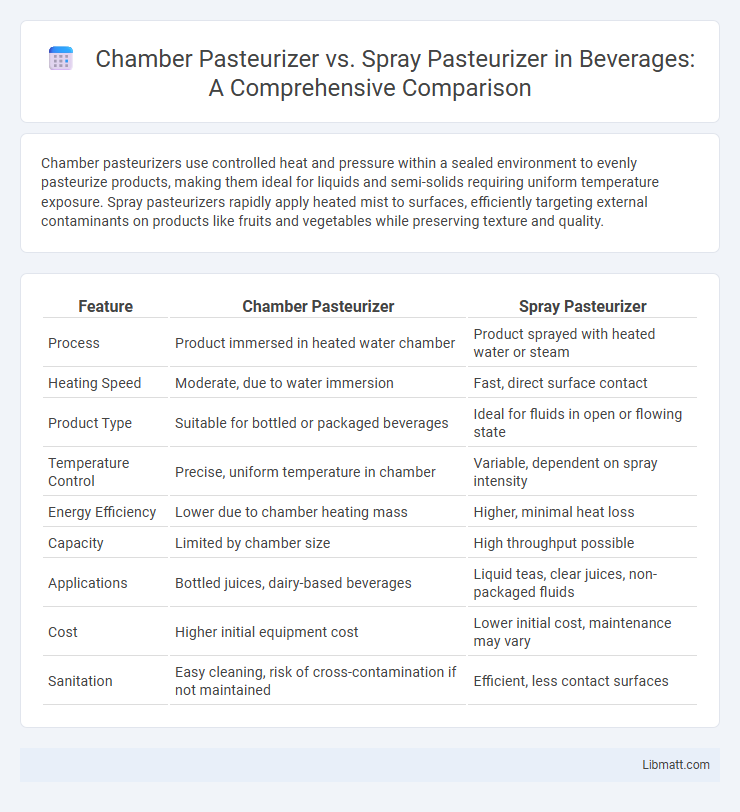

Chamber pasteurizers use controlled heat and pressure within a sealed environment to evenly pasteurize products, making them ideal for liquids and semi-solids requiring uniform temperature exposure. Spray pasteurizers rapidly apply heated mist to surfaces, efficiently targeting external contaminants on products like fruits and vegetables while preserving texture and quality.

Table of Comparison

| Feature | Chamber Pasteurizer | Spray Pasteurizer |

|---|---|---|

| Process | Product immersed in heated water chamber | Product sprayed with heated water or steam |

| Heating Speed | Moderate, due to water immersion | Fast, direct surface contact |

| Product Type | Suitable for bottled or packaged beverages | Ideal for fluids in open or flowing state |

| Temperature Control | Precise, uniform temperature in chamber | Variable, dependent on spray intensity |

| Energy Efficiency | Lower due to chamber heating mass | Higher, minimal heat loss |

| Capacity | Limited by chamber size | High throughput possible |

| Applications | Bottled juices, dairy-based beverages | Liquid teas, clear juices, non-packaged fluids |

| Cost | Higher initial equipment cost | Lower initial cost, maintenance may vary |

| Sanitation | Easy cleaning, risk of cross-contamination if not maintained | Efficient, less contact surfaces |

Introduction to Chamber and Spray Pasteurizers

Chamber pasteurizers utilize a sealed environment to apply steam or hot water uniformly around packaged products, ensuring thorough heat penetration and extended shelf life. Spray pasteurizers employ high-pressure nozzles to atomize hot water over product surfaces, allowing rapid temperature control ideal for liquid or semi-liquid foods. Both technologies optimize pasteurization by balancing heat distribution, processing speed, and product integrity, making them essential in food safety and preservation.

How Chamber Pasteurizers Work

Chamber pasteurizers operate by sealing products inside a closed chamber where they undergo controlled heating through the circulation of hot water or steam, ensuring uniform temperature distribution around the items. This method allows precise temperature control and gentle handling, making it ideal for delicate or packaged products, preserving quality while effectively killing pathogens. Compared to spray pasteurizers, chamber pasteurizers offer enhanced protection from contamination and are often used for liquid foods, dairy, and beverages requiring batch processing.

How Spray Pasteurizers Operate

Spray pasteurizers operate by atomizing the liquid product into fine droplets, which are then rapidly heated through direct contact with hot air or steam, ensuring uniform temperature distribution and efficient heat transfer. This method significantly reduces processing time and preserves the product's sensory and nutritional qualities compared to chamber pasteurizers, which use immersion heating. Your choice of spray pasteurizer can enhance production speed and maintain product freshness while minimizing energy consumption.

Key Differences Between Chamber and Spray Pasteurizers

Chamber pasteurizers use a sealed environment to heat product batches uniformly, ensuring consistent temperature control ideal for viscous liquids and delicate items. Spray pasteurizers rapidly heat liquids by atomizing them into fine droplets within hot air, enabling efficient pasteurization for thin, pumpable fluids like juices and milk. Your choice depends on product viscosity, batch size, and processing speed, with chamber systems favoring batch control and spray systems excelling in continuous high-throughput applications.

Efficiency and Throughput Comparison

Chamber pasteurizers offer higher efficiency for small batches by evenly heating products in a sealed environment, minimizing heat loss and maintaining consistent temperatures. Spray pasteurizers excel in throughput with continuous processing capabilities, rapidly treating liquid products through a fine mist, which allows for faster cooling and heating cycles. Selecting between the two depends on production scale, as chamber pasteurizers suit artisanal or low-volume runs, while spray pasteurizers are optimal for high-volume, continuous operations.

Product Compatibility and Versatility

Chamber pasteurizers offer superior product compatibility by accommodating various container shapes and sizes, including bottles, jars, and pouches, making them ideal for versatile production lines. Spray pasteurizers excel in treating liquid products with consistent viscosity, ensuring uniform heat distribution without compromising product quality. Your choice depends on whether you prioritize handling diverse packaging formats or specialized liquid processing.

Energy Consumption and Cost Implications

Chamber pasteurizers generally consume more energy due to extended heating cycles and larger water volumes, leading to higher operational costs compared to spray pasteurizers that use rapid heating with less water. Spray pasteurizers optimize energy efficiency by applying hot water directly onto products, significantly reducing both energy consumption and maintenance expenses. Your choice between the two should consider these factors to balance initial investment with long-term cost savings.

Maintenance Requirements and Downtime

Chamber pasteurizers typically require more intensive maintenance due to their complex mechanical parts and longer processing cycles, resulting in higher downtime during routine servicing. Spray pasteurizers feature simpler designs with fewer moving components, leading to easier maintenance and reduced operational interruptions. Facility managers often prefer spray pasteurizers for environments where minimizing downtime is critical to maintaining continuous production flow.

Quality Control and Food Safety Considerations

Chamber pasteurizers ensure consistent temperature uniformity, reducing the risk of underprocessing and preserving product quality through controlled immersion times and thermal exposure. Spray pasteurizers offer rapid heat transfer ideal for high-viscosity liquids but require precise monitoring to prevent uneven pasteurization and potential microbial survival. Both technologies demand rigorous validation and real-time monitoring systems to meet food safety standards and achieve optimal pathogen reduction.

Choosing the Right Pasteurizer for Your Production Needs

Chamber pasteurizers excel in batch processing, offering precise temperature control and uniform heating ideal for small to medium production runs. Spray pasteurizers provide continuous flow pasteurization, enhancing efficiency and reducing processing time for large-scale operations where volume and speed are critical. Your choice depends on production volume, product type, and desired throughput to ensure optimal pasteurization performance and product quality.

Chamber pasteurizer vs spray pasteurizer Infographic

libmatt.com

libmatt.com