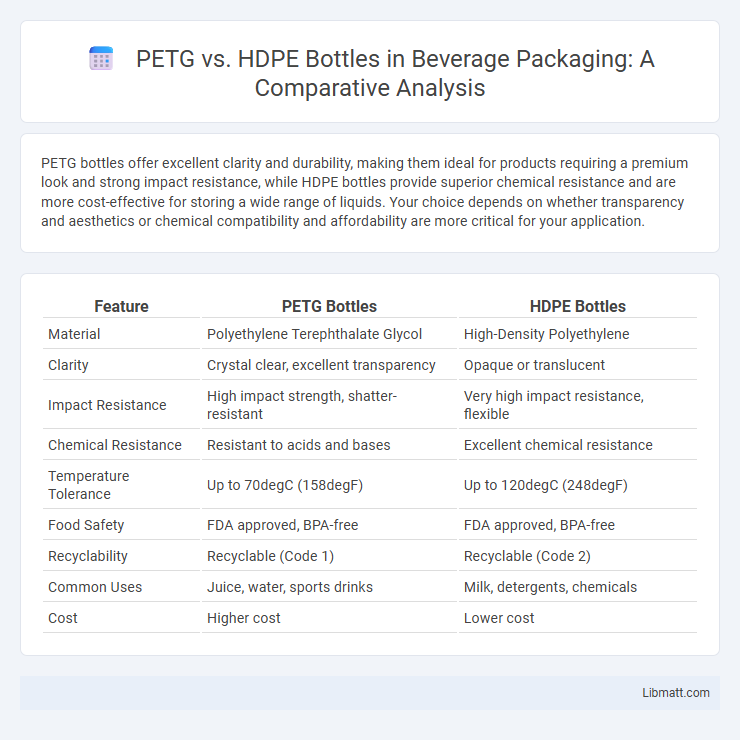

PETG bottles offer excellent clarity and durability, making them ideal for products requiring a premium look and strong impact resistance, while HDPE bottles provide superior chemical resistance and are more cost-effective for storing a wide range of liquids. Your choice depends on whether transparency and aesthetics or chemical compatibility and affordability are more critical for your application.

Table of Comparison

| Feature | PETG Bottles | HDPE Bottles |

|---|---|---|

| Material | Polyethylene Terephthalate Glycol | High-Density Polyethylene |

| Clarity | Crystal clear, excellent transparency | Opaque or translucent |

| Impact Resistance | High impact strength, shatter-resistant | Very high impact resistance, flexible |

| Chemical Resistance | Resistant to acids and bases | Excellent chemical resistance |

| Temperature Tolerance | Up to 70degC (158degF) | Up to 120degC (248degF) |

| Food Safety | FDA approved, BPA-free | FDA approved, BPA-free |

| Recyclability | Recyclable (Code 1) | Recyclable (Code 2) |

| Common Uses | Juice, water, sports drinks | Milk, detergents, chemicals |

| Cost | Higher cost | Lower cost |

Introduction to PETG and HDPE Bottles

PETG bottles are made from polyethylene terephthalate glycol, known for their clarity, durability, and excellent impact resistance, making them ideal for packaging beverages and cosmetics. HDPE bottles, composed of high-density polyethylene, offer superior chemical resistance and rigidity, commonly used for storing cleaning products, detergents, and milk. Your choice between PETG and HDPE bottles depends on the application requirements, including durability, transparency, and compatibility with the contents.

Material Composition and Properties

PETG bottles are made from glycol-modified polyethylene terephthalate, offering excellent clarity, impact resistance, and chemical stability, making them ideal for packaging sensitive products. HDPE bottles, composed of high-density polyethylene, provide superior strength, chemical resistance, and UV protection, which suits them for heavy-duty and outdoor applications. Your choice depends on whether you prioritize transparency and flexibility (PETG) or durability and resistance to harsh environments (HDPE).

Manufacturing Processes

PETG bottles are produced using injection molding or extrusion blow molding, enabling precise control over thickness and clarity, which results in highly transparent and impact-resistant containers. HDPE bottles are typically manufactured through extrusion blow molding, offering excellent chemical resistance and durability, though with lower clarity compared to PETG. The manufacturing process of PETG allows for faster cycle times and better detail retention, while HDPE provides cost-effective scalability ideal for bulk production.

Strength and Durability Comparison

PETG bottles offer superior clarity and impact resistance, making them highly durable for packaging applications that require visibility and toughness. HDPE bottles boast excellent chemical resistance and high tensile strength, providing robust performance in harsh environments and against physical stress. Your choice between PETG and HDPE bottles should consider the specific strength and durability requirements of your product to ensure optimal protection and longevity.

Chemical Resistance and Safety

PETG bottles offer excellent chemical resistance against acids and alcohols, making them safe for storing a variety of substances with minimal risk of degradation. HDPE bottles provide superior resistance to bases, detergents, and oils, ensuring durability and safety for more aggressive chemicals. To ensure your stored liquids remain uncontaminated, choosing the right bottle material based on specific chemical compatibility is essential.

Environmental Impact and Recyclability

PETG bottles offer better clarity and durability but are less recyclable than HDPE bottles, which are widely accepted in curbside recycling programs. HDPE's lower environmental impact stems from its higher recyclability rate and the ability to be remanufactured into new containers, reducing landfill waste. Choosing HDPE bottles supports a more sustainable cycle, minimizing your environmental footprint through efficient recycling processes.

Cost Efficiency and Market Availability

PETG bottles offer moderate cost efficiency with a slightly higher price point than HDPE but provide excellent clarity and durability, making them ideal for premium packaging. HDPE bottles are highly cost-effective, widely available, and favored for their chemical resistance and lightweight nature, driving strong market demand in various industries. You should consider HDPE if budget constraints and broad accessibility are priorities, while PETG suits applications needing superior aesthetics and strength.

Applications and Industry Uses

PETG bottles offer excellent clarity and impact resistance, making them ideal for cosmetic, pharmaceutical, and food packaging where product visibility is crucial. HDPE bottles provide superior chemical resistance and durability, commonly used in industrial, cleaning, and chemical applications requiring secure and robust containment. Your choice between PETG and HDPE bottles depends on the specific industry needs, balancing transparency with chemical stability.

Design Flexibility and Customization Options

PETG bottles offer superior design flexibility and customization options due to their excellent clarity, impact resistance, and ability to be thermoformed into complex shapes, making them ideal for intricate branding and labeling. HDPE bottles provide robust durability and chemical resistance with easier molding processes but have more limited transparency and shape variety compared to PETG. Manufacturers favor PETG for premium visual appeal and HDPE for cost-effective, functional designs in various applications.

Choosing the Right Bottle: PETG vs HDPE

PETG bottles offer superior clarity and impact resistance, making them ideal for products requiring high visibility and durability. HDPE bottles provide excellent chemical resistance and are more cost-effective, suitable for storing aggressive substances or for large-scale distribution. Selecting between PETG and HDPE depends on product compatibility, budget constraints, and the need for visual appeal or performance under stress.

PETG vs HDPE bottles Infographic

libmatt.com

libmatt.com