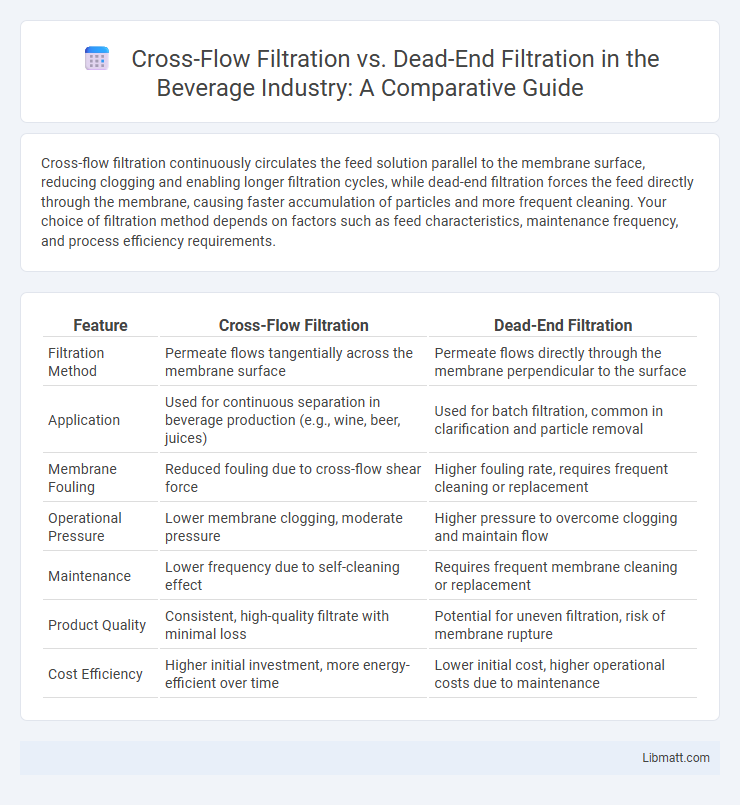

Cross-flow filtration continuously circulates the feed solution parallel to the membrane surface, reducing clogging and enabling longer filtration cycles, while dead-end filtration forces the feed directly through the membrane, causing faster accumulation of particles and more frequent cleaning. Your choice of filtration method depends on factors such as feed characteristics, maintenance frequency, and process efficiency requirements.

Table of Comparison

| Feature | Cross-Flow Filtration | Dead-End Filtration |

|---|---|---|

| Filtration Method | Permeate flows tangentially across the membrane surface | Permeate flows directly through the membrane perpendicular to the surface |

| Application | Used for continuous separation in beverage production (e.g., wine, beer, juices) | Used for batch filtration, common in clarification and particle removal |

| Membrane Fouling | Reduced fouling due to cross-flow shear force | Higher fouling rate, requires frequent cleaning or replacement |

| Operational Pressure | Lower membrane clogging, moderate pressure | Higher pressure to overcome clogging and maintain flow |

| Maintenance | Lower frequency due to self-cleaning effect | Requires frequent membrane cleaning or replacement |

| Product Quality | Consistent, high-quality filtrate with minimal loss | Potential for uneven filtration, risk of membrane rupture |

| Cost Efficiency | Higher initial investment, more energy-efficient over time | Lower initial cost, higher operational costs due to maintenance |

Introduction to Cross-Flow and Dead-End Filtration

Cross-flow filtration and dead-end filtration are critical membrane separation techniques used in water treatment, biotechnology, and food processing. Cross-flow filtration continuously circulates the feed stream tangentially across the membrane surface, minimizing clogging and enabling longer operation times, while dead-end filtration forces the entire feed stream directly through the membrane, causing faster particle accumulation and more frequent cleaning. Your choice between these methods depends on factors like feed composition, desired filtration efficiency, and maintenance requirements.

Fundamental Principles of Cross-Flow Filtration

Cross-flow filtration operates by continuously flowing the feed solution tangentially across the membrane surface, minimizing the buildup of retained particles and reducing membrane fouling. This dynamic flow maintains higher filtration efficiency and flux compared to dead-end filtration, where all feed passes perpendicularly through the membrane causing rapid cake formation. Understanding your system's needs for flux, recovery, and cleaning cycles is essential when choosing the optimal filtration method.

Core Mechanisms of Dead-End Filtration

Dead-end filtration operates by forcing the feed stream perpendicular to the filter media, causing particles to accumulate and form a cake layer on the membrane surface. This mechanism relies on particle retention directly at the filter interface, leading to progressive clogging and increased pressure drop over time. You must regularly clean or replace the filter to maintain efficiency, as the buildup hinders flow and filtration performance.

Key Differences Between Cross-Flow and Dead-End Filtration

Cross-flow filtration circulates the feed fluid parallel to the membrane surface, reducing filter cake buildup and enabling continuous operation, while dead-end filtration forces fluid perpendicular through the membrane, leading to faster fouling and frequent cleaning. Cross-flow systems offer higher efficiency and longer membrane life, making them ideal for processing large volumes of liquids such as in water treatment or protein purification. Understanding these key differences helps you select the appropriate filtration method based on your application's throughput and maintenance requirements.

Advantages of Cross-Flow Filtration Systems

Cross-flow filtration systems offer significant advantages over dead-end filtration by continuously sweeping the membrane surface, reducing fouling and extending membrane life. These systems provide higher permeate flux and improved filtration efficiency, making them ideal for processing fluids with high solids content. You benefit from lower maintenance requirements and consistent performance in applications such as wastewater treatment, food processing, and biopharmaceutical manufacturing.

Benefits and Limitations of Dead-End Filtration

Dead-end filtration offers simple operation and low initial cost, making it suitable for applications requiring the removal of larger particulates in low-volume processes. However, its main limitation is rapid membrane fouling due to particle accumulation on the filter surface, which reduces flux and necessitates frequent cleaning or replacement. This approach can lead to higher downtime and operational costs compared to cross-flow filtration, which maintains continuous cleaning of the membrane surface.

Applications of Cross-Flow Filtration in Industry

Cross-flow filtration is widely applied in the food and beverage industry for processes like whey protein concentration and juice clarification, providing efficient separation with minimal membrane fouling. In wastewater treatment, it effectively removes suspended solids and microorganisms, enhancing water recovery and quality. Your operations can benefit from its continuous flow design, which sustains membrane performance in pharmaceutical and biotechnology applications, including cell harvesting and protein purification.

Common Uses of Dead-End Filtration Technology

Dead-end filtration technology is commonly used in laboratory sample preparation, water purification, and industrial process filtration where simplicity and cost-effectiveness are prioritized. This method efficiently removes particulate matter by forcing the entire fluid through a filter, making it ideal for low-volume applications and fluids with low solids content. Your choice of dead-end filtration suits processes requiring straightforward, disposable filter setups and frequent filter replacements.

Factors Influencing Filtration Method Selection

Filtration method selection depends on factors such as feed suspension concentration, desired permeate quality, and membrane fouling propensity. Cross-flow filtration is preferred for high-solid-content feeds and continuous processes due to its ability to reduce cake buildup and maintain flux. Dead-end filtration suits low-solid suspensions and batch operations where simplicity and lower operational costs are prioritized.

Future Trends in Filtration Technology

Future trends in filtration technology are driving innovations in cross-flow filtration systems, emphasizing enhanced membrane materials that improve fouling resistance and energy efficiency. Dead-end filtration is evolving with advances in back-flushing techniques and novel filter media to extend filter life and reduce downtime. Integration of smart sensors and AI-driven process optimization is expected to revolutionize both cross-flow and dead-end filtration, enabling real-time monitoring and predictive maintenance.

Cross-flow filtration vs dead-end filtration Infographic

libmatt.com

libmatt.com