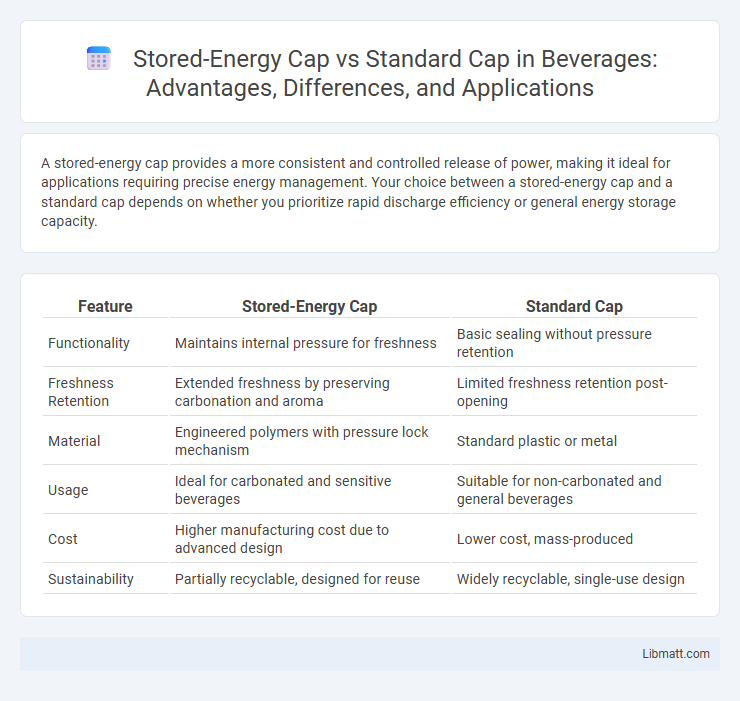

A stored-energy cap provides a more consistent and controlled release of power, making it ideal for applications requiring precise energy management. Your choice between a stored-energy cap and a standard cap depends on whether you prioritize rapid discharge efficiency or general energy storage capacity.

Table of Comparison

| Feature | Stored-Energy Cap | Standard Cap |

|---|---|---|

| Functionality | Maintains internal pressure for freshness | Basic sealing without pressure retention |

| Freshness Retention | Extended freshness by preserving carbonation and aroma | Limited freshness retention post-opening |

| Material | Engineered polymers with pressure lock mechanism | Standard plastic or metal |

| Usage | Ideal for carbonated and sensitive beverages | Suitable for non-carbonated and general beverages |

| Cost | Higher manufacturing cost due to advanced design | Lower cost, mass-produced |

| Sustainability | Partially recyclable, designed for reuse | Widely recyclable, single-use design |

Introduction to Stored-Energy Caps and Standard Caps

Stored-energy caps store mechanical energy in a spring or similar device to provide quick, consistent torque release, enhancing precision in applications like paintball markers and pneumatic tools. Standard caps typically rely on direct manual operation without energy storage, resulting in slower and less repeatable actuation. The stored-energy mechanism enables faster reset and improved performance compared to conventional standard caps.

How Stored-Energy Caps Work

Stored-energy caps use compressed air or gas to maintain consistent pressure, ensuring smooth and reliable fluid delivery in hydraulic systems. Unlike standard caps, which rely on simple sealing mechanisms, stored-energy caps store potential energy that is released when needed to stabilize system performance. Your hydraulic equipment benefits from reduced pressure fluctuations and enhanced operational efficiency with stored-energy cap technology.

Key Features of Standard Caps

Standard caps offer reliable closure with simple, durable designs ideal for everyday containers such as water bottles and jars. These caps provide consistent sealing performance, maintaining product freshness without the complexity of stored-energy mechanisms. Your packaging benefits from cost-effective production and ease of use, making standard caps a practical choice for routine applications.

Energy Efficiency Comparison

Stored-energy caps provide higher energy efficiency by maintaining consistent airflow with less pressure drop compared to standard caps, which often cause greater resistance and energy loss. The design of stored-energy caps minimizes turbulence and reduces the workload on ventilation systems, leading to lower operational costs and improved system performance. In contrast, standard caps typically allow more energy dissipation due to higher drag and less optimized airflow pathways.

Performance and Reliability

Stored-energy caps deliver superior performance by providing rapid, high-energy bursts that enhance power stability in electronic circuits, contrasting with standard caps that discharge energy more gradually. Their robust design ensures higher reliability under demanding conditions, reducing voltage drops and improving the lifespan of your devices. Choosing a stored-energy capacitor can significantly boost your system's efficiency and operational consistency.

Safety Considerations

Stored-energy capacitors pose higher safety risks due to their ability to retain charge long after power is removed, necessitating stringent discharge procedures and protective measures to prevent electrical shock or equipment damage. Standard capacitors discharge more rapidly and generally present lower hazards, but still require careful handling to avoid short circuits or burns. Understanding the differences in energy retention and discharge characteristics is critical for safe installation, maintenance, and emergency response in electrical systems.

Cost and Value Analysis

Stored-energy caps typically offer greater cost efficiency over time due to their ability to retain and release energy as needed, reducing overall energy consumption compared to standard caps. Standard caps involve lower upfront costs but often lead to higher operational expenses due to less efficient energy usage and increased maintenance requirements. Evaluating total cost of ownership reveals stored-energy caps provide superior value by lowering long-term energy costs and enhancing system reliability.

Application and Industry Use Cases

Stored-energy caps excel in high-torque applications such as heavy machinery and automotive assembly lines, where rapid, consistent fastening is critical. Standard caps are suited for general manufacturing and maintenance tasks with moderate torque requirements, commonly found in electronics and household appliance production. Your choice between stored-energy and standard caps depends on the precision, speed, and durability demands of your specific industrial application.

Maintenance and Longevity

Stored-energy caps require less frequent maintenance due to their robust design, which minimizes wear and tear over time. Standard caps often need regular inspection and replacement because of their simpler mechanisms that are more susceptible to damage. The enhanced durability of stored-energy caps contributes to a significantly longer service life, reducing downtime and operational costs.

Choosing the Right Cap for Your Needs

Stored-energy capacitors excel in high-power applications requiring rapid discharge and energy release, making them ideal for pulsed power and power conditioning. Standard capacitors suit continuous, lower-power tasks like filtering and energy storage in everyday electronics due to their stable voltage tolerance and longer lifespan. Selecting the right cap depends on specific requirements such as voltage rating, energy density, discharge time, and application environment to ensure optimal performance and durability.

Stored-energy cap vs standard cap Infographic

libmatt.com

libmatt.com