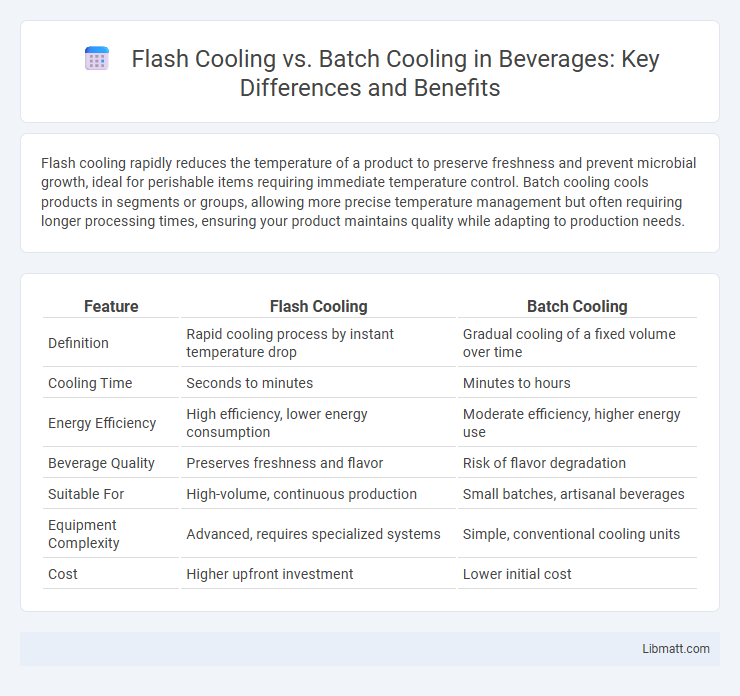

Flash cooling rapidly reduces the temperature of a product to preserve freshness and prevent microbial growth, ideal for perishable items requiring immediate temperature control. Batch cooling cools products in segments or groups, allowing more precise temperature management but often requiring longer processing times, ensuring your product maintains quality while adapting to production needs.

Table of Comparison

| Feature | Flash Cooling | Batch Cooling |

|---|---|---|

| Definition | Rapid cooling process by instant temperature drop | Gradual cooling of a fixed volume over time |

| Cooling Time | Seconds to minutes | Minutes to hours |

| Energy Efficiency | High efficiency, lower energy consumption | Moderate efficiency, higher energy use |

| Beverage Quality | Preserves freshness and flavor | Risk of flavor degradation |

| Suitable For | High-volume, continuous production | Small batches, artisanal beverages |

| Equipment Complexity | Advanced, requires specialized systems | Simple, conventional cooling units |

| Cost | Higher upfront investment | Lower initial cost |

Introduction to Flash Cooling and Batch Cooling

Flash cooling rapidly reduces temperature by quickly passing products through a cooling tunnel, preserving texture and quality by minimizing ice crystal formation. Batch cooling involves cooling products in larger quantities within insulated containers or rooms, allowing for uniform temperature reduction but requiring more time and energy. Understanding the differences between flash cooling and batch cooling helps you select the optimal method for preserving your product's freshness and shelf life.

Understanding the Principles of Flash Cooling

Flash cooling rapidly reduces temperature by exposing hot products to cold air or fluids, minimizing microbial growth and preserving quality in industries like food processing and pharmaceuticals. This rapid thermal exchange prevents ice crystal formation, maintaining texture and nutritional value compared to batch cooling that relies on slower temperature equalization in bulk. Leveraging principles of heat transfer and thermodynamics, flash cooling optimizes efficiency by reducing cooling time and energy consumption while ensuring product safety.

Overview of Batch Cooling Methods

Batch cooling methods involve cooling a fixed quantity of product in discrete steps within insulated containers or chilled rooms. These methods use temperature control techniques such as immersion in chilled water, air blast cooling, or contact with cooled surfaces, allowing precise management of cooling rates and preventing microbial growth. Your choice of batch cooling can significantly impact the preservation of food quality, texture, and shelf life.

Key Differences Between Flash Cooling and Batch Cooling

Flash cooling rapidly reduces temperature by quickly exposing products to very low temperatures, preserving freshness and texture, while batch cooling cools products gradually in large quantities, allowing for better control over uniformity but requiring more time. Flash cooling is ideal for heat-sensitive or perishable goods, utilizing techniques such as cryogenic cooling or blast chillers, whereas batch cooling suits bulk processing with consistent thermal conditions. Efficiency in energy use varies, with flash cooling often consuming more power for rapid temperature drops, but offering shorter processing cycles compared to the slower, energy-efficient batch cooling method.

Efficiency and Speed Comparison

Flash cooling offers significantly higher efficiency and speed compared to batch cooling by rapidly reducing temperature through direct contact with a cooling medium, minimizing product degradation and energy consumption. Batch cooling involves slower temperature reduction in large volumes, leading to longer processing times and increased energy use to maintain uniform cooling. In industrial food processing and pharmaceutical applications, flash cooling enhances throughput and preserves product quality, making it the preferred choice where rapid temperature control is critical.

Impact on Product Quality and Safety

Flash cooling rapidly reduces the temperature of products, minimizing microbial growth and preserving freshness, which significantly enhances both product quality and safety. Batch cooling, being slower, increases the risk of microbial proliferation and enzymatic activity that can degrade taste, texture, and safety profiles. Rapid temperature control in flash cooling systems is critical for maintaining optimal shelf life and reducing contamination risks compared to conventional batch cooling methods.

Energy Consumption and Sustainability

Flash cooling significantly reduces energy consumption by rapidly lowering temperatures in a continuous process, minimizing the need for prolonged refrigeration cycles. Batch cooling involves intermittent cooling, which typically requires more energy due to repeated start-stop cycles and longer cooling durations. The efficiency of flash cooling contributes to enhanced sustainability by lowering carbon emissions and operational costs compared to traditional batch cooling methods.

Equipment and Operational Requirements

Flash cooling requires specialized equipment such as plate or tubular heat exchangers designed for rapid temperature reduction, ensuring precise control and minimal bacterial growth. Batch cooling typically involves larger vessels or tanks with cooling jackets or immersion coils, necessitating longer processing times and increased monitoring to maintain product quality. Your choice between these methods depends on the scale of operation and the specific cooling rate required for your product.

Best Applications for Each Cooling Method

Flash cooling is ideal for applications requiring rapid temperature reduction to preserve freshness and prevent microbial growth, such as in seafood, dairy products, and freshly baked goods. Batch cooling suits products needing gradual cooling for texture retention and uniform temperature, commonly used in meats, fermented foods, and large volume liquids. Your choice depends on product sensitivity and processing speed to ensure quality and safety.

Choosing the Right Cooling Solution for Your Needs

Flash cooling rapidly reduces the temperature of products, preserving freshness and quality by minimizing bacterial growth, making it ideal for perishable items requiring quick processing. Batch cooling offers controlled, gradual temperature reduction, providing energy efficiency and consistency for products with less sensitivity to immediate cooling. You should select flash cooling for fast turnover and high product quality, while batch cooling suits bulk processing with steady cooling demands.

Flash cooling vs batch cooling Infographic

libmatt.com

libmatt.com