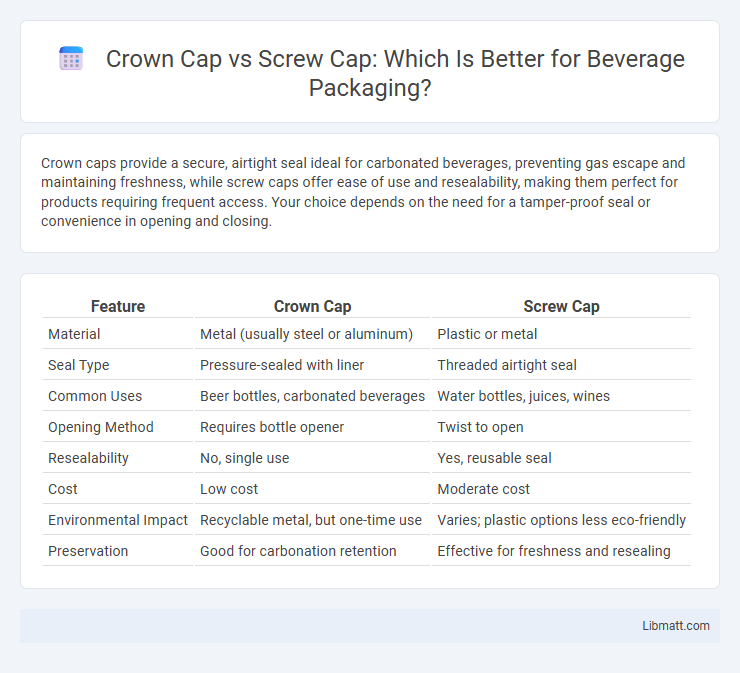

Crown caps provide a secure, airtight seal ideal for carbonated beverages, preventing gas escape and maintaining freshness, while screw caps offer ease of use and resealability, making them perfect for products requiring frequent access. Your choice depends on the need for a tamper-proof seal or convenience in opening and closing.

Table of Comparison

| Feature | Crown Cap | Screw Cap |

|---|---|---|

| Material | Metal (usually steel or aluminum) | Plastic or metal |

| Seal Type | Pressure-sealed with liner | Threaded airtight seal |

| Common Uses | Beer bottles, carbonated beverages | Water bottles, juices, wines |

| Opening Method | Requires bottle opener | Twist to open |

| Resealability | No, single use | Yes, reusable seal |

| Cost | Low cost | Moderate cost |

| Environmental Impact | Recyclable metal, but one-time use | Varies; plastic options less eco-friendly |

| Preservation | Good for carbonation retention | Effective for freshness and resealing |

Introduction: Crown Cap vs Screw Cap

Crown caps provide a traditional seal commonly used for carbonated beverages, ensuring a secure closure that preserves carbonation and freshness. Screw caps offer convenience and resealing capabilities, ideal for wines and beverages requiring controlled oxygen exposure. Choosing between crown cap vs screw cap depends on your product's need for freshness retention, ease of use, and packaging style.

Historical Evolution of Bottle Closures

Crown caps, invented in 1892 by William Painter, revolutionized bottle closures by providing a reliable and tamper-proof seal primarily for carbonated beverages. Screw caps emerged later in the 20th century, offering ease of use and resealability, especially popular in the wine and non-carbonated beverage industries. The transition from crown to screw caps reflects advancements in sealing technology and consumer demands for convenience and preservation.

Material Composition and Design Differences

Crown caps are typically made from tin-plated steel with a polyethylene liner, featuring a crimped design that secures the cap tightly to the bottle's lip, making them ideal for carbonated beverages. Screw caps consist of aluminum or plastic with a threaded design that twists onto corresponding threads on the bottle neck, providing an airtight seal and ease of resealing. The material composition and structural design of crown caps limit resealing, whereas screw caps emphasize convenience and repeated use without compromising freshness.

Oxygen Permeability and Beverage Preservation

Crown caps provide a nearly airtight seal with extremely low oxygen permeability, making them ideal for preserving the freshness and carbonation of beverages such as beer. Screw caps, while convenient and resealable, tend to have slightly higher oxygen permeability, which can lead to faster oxidation and reduced shelf life in sensitive drinks. Choosing the right closure for your beverage depends on balancing oxygen barrier properties with usability to maintain optimal quality.

Impact on Flavor and Shelf Life

Crown caps provide an airtight seal that preserves carbonation and maintains the original flavor profile of beverages, particularly in beer, enhancing shelf life by preventing oxygen ingress. Screw caps offer reliable resealing capabilities, reducing oxidation risk after opening and extending freshness, though they may be less effective in retaining carbonation compared to crown caps. The choice between crown cap and screw cap directly influences flavor retention and shelf stability, with crown caps favored for long-term preservation and screw caps preferred for convenience and resealing.

Ease of Use and Consumer Convenience

Screw caps offer superior ease of use compared to crown caps, enabling consumers to open and reseal bottles effortlessly without additional tools. Crown caps require a bottle opener, which can be inconvenient and less practical for on-the-go consumption. The resealability of screw caps enhances consumer convenience by maintaining freshness and preventing spills after initial opening.

Manufacturing and Sustainability Considerations

Crown caps are manufactured using metal stamping processes that consume significant energy and generate metal waste, whereas screw caps often utilize plastic or aluminum, benefiting from more flexible molding techniques with potentially lower environmental footprints. Sustainability considerations favor screw caps due to their recyclability and easier integration into circular economy models, while crown caps pose challenges in recycling because of their composite materials and coatings. You can reduce environmental impact by selecting closures that align with sustainable manufacturing practices and support recycling infrastructure.

Market Preferences and Regional Trends

Screw caps dominate the wine packaging market in New World regions such as Australia and New Zealand due to their superior airtight seal and ease of use, contributing to higher consumer acceptance. Crown caps retain strong popularity in the beer and craft beverage sectors globally, especially in North America and Europe, where traditional packaging preferences prevail. Market trends indicate increasing adoption of screw caps in emerging wine markets, reflecting shifting consumer attitudes toward convenience and product preservation.

Cost Comparison: Production and Distribution

Crown caps generally have lower production costs due to simpler materials and manufacturing processes, making them economical for large-scale beverage bottling. Screw caps, while slightly more expensive to produce because of precision threading and sealing mechanisms, offer advantages in distribution such as resealability, reducing product waste and enhancing consumer convenience. The choice between crown and screw caps hinges on balancing initial production expenses against distribution benefits and end-user functionality.

Conclusion: Which Cap Is Superior?

Screw caps offer superior resealability and convenience for consumers, making them ideal for products requiring repeated access. Crown caps provide a more secure, tamper-evident seal, preferred in industries like beer and soda for maintaining carbonation and freshness. Your choice depends on whether resealability or initial seal strength aligns better with your product needs.

Crown cap vs screw cap Infographic

libmatt.com

libmatt.com