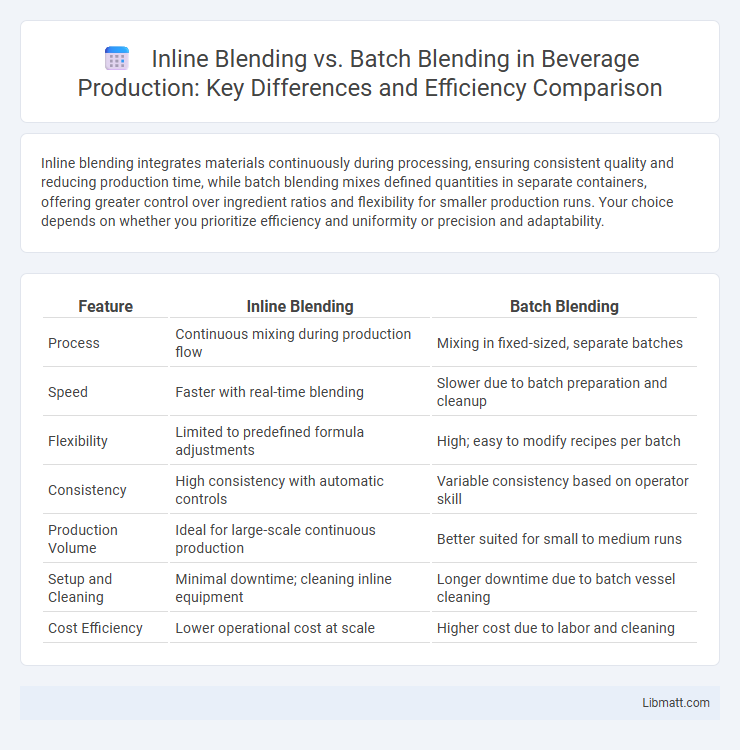

Inline blending integrates materials continuously during processing, ensuring consistent quality and reducing production time, while batch blending mixes defined quantities in separate containers, offering greater control over ingredient ratios and flexibility for smaller production runs. Your choice depends on whether you prioritize efficiency and uniformity or precision and adaptability.

Table of Comparison

| Feature | Inline Blending | Batch Blending |

|---|---|---|

| Process | Continuous mixing during production flow | Mixing in fixed-sized, separate batches |

| Speed | Faster with real-time blending | Slower due to batch preparation and cleanup |

| Flexibility | Limited to predefined formula adjustments | High; easy to modify recipes per batch |

| Consistency | High consistency with automatic controls | Variable consistency based on operator skill |

| Production Volume | Ideal for large-scale continuous production | Better suited for small to medium runs |

| Setup and Cleaning | Minimal downtime; cleaning inline equipment | Longer downtime due to batch vessel cleaning |

| Cost Efficiency | Lower operational cost at scale | Higher cost due to labor and cleaning |

Introduction to Blending Techniques

Inline blending integrates ingredients continuously during the production process, optimizing efficiency and product consistency in industries like food and pharmaceuticals. Batch blending involves mixing predefined amounts of components in discrete batches, offering precise control over formulation and quality. Selecting between inline and batch blending depends on production volume, process control requirements, and product specifications.

What is Inline Blending?

Inline blending is a continuous process where raw materials are mixed directly within the production line, ensuring consistent product quality by maintaining precise control over ingredient ratios in real-time. This technique reduces contamination risks and minimizes production downtime compared to batch blending, which processes materials in separate, discrete batches. Inline blending is widely utilized in industries such as pharmaceuticals, food processing, and chemicals for its efficiency and accuracy.

What is Batch Blending?

Batch blending is a process used in manufacturing and production where multiple ingredients or raw materials are combined in specific quantities within a batch before further processing. This method ensures precise control over the composition, allowing for consistent product quality across each production run. Understanding batch blending helps you optimize resource use, reduce waste, and maintain uniformity in your final product.

Key Differences Between Inline and Batch Blending

Inline blending continuously mixes ingredients during processing, ensuring uniform product quality with real-time adjustments based on immediate feedback from flow meters or sensors. Batch blending involves combining discrete quantities of materials in a separate vessel, allowing precise control over ingredient ratios but requiring longer processing times and additional handling. Inline blending suits high-speed production lines, whereas batch blending provides flexibility for varied formulations and smaller production volumes.

Advantages of Inline Blending

Inline blending offers precise real-time control over ingredient mix ratios, ensuring consistent product quality and reducing material waste. This method minimizes downtime by eliminating the need for separate batch preparation, enhancing overall production efficiency and throughput. Your manufacturing process benefits from streamlined operations and faster response to formulation adjustments with inline blending technology.

Benefits of Batch Blending

Batch blending enhances consistency by mixing large quantities of ingredients uniformly, reducing variability in product quality. It allows greater control over formulation adjustments, leading to improved accuracy and scalability for manufacturing processes. Your production efficiency increases as batch blending minimizes downtime and facilitates easier quality testing before distribution.

Challenges and Limitations of Inline Blending

Inline blending faces challenges such as limited flexibility in adjusting formulations on the fly, leading to potential product inconsistencies. Equipment complexity and high initial investment costs can restrict scalability and maintenance efficiency. Real-time quality control is critical but difficult to implement, increasing the risk of deviations in blend uniformity.

Drawbacks of Batch Blending

Batch blending can lead to inconsistencies in product quality due to variations between different batches and longer production times compared to inline blending. The need for separate storage tanks increases contamination risks and requires more cleaning, raising operational costs. Additionally, batch blending often results in higher inventory levels and delayed responsiveness to changing demand or formulation adjustments.

Factors to Consider When Choosing a Blending Method

Choosing between inline blending and batch blending depends on factors like production volume, flexibility requirements, and process control precision. Inline blending suits continuous processes with high throughput and consistent formulation, ensuring real-time quality monitoring and reducing downtime. Batch blending offers greater flexibility for varying product specifications and smaller production runs, allowing for more detailed quality checks and easier recipe adjustments.

Conclusion: Selecting the Right Blending Technique

Choosing between inline blending and batch blending depends on operational scale, product consistency requirements, and production speed. Inline blending offers continuous, real-time mixing ideal for high-volume processes with precise quality control, while batch blending provides flexibility and control suited for smaller or varying production runs. Evaluating factors such as equipment costs, process efficiency, and product specifications ensures the selection of the most effective blending technique for optimal results.

Inline blending vs batch blending Infographic

libmatt.com

libmatt.com