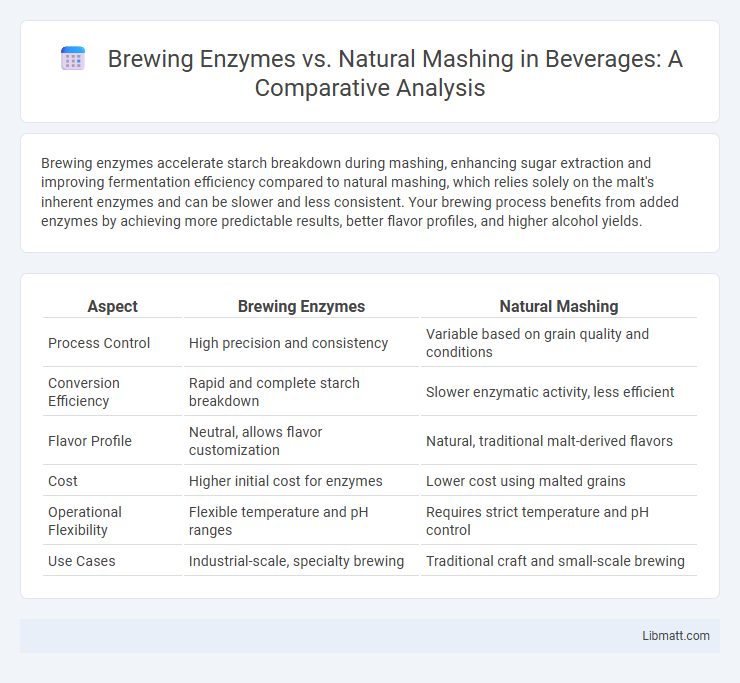

Brewing enzymes accelerate starch breakdown during mashing, enhancing sugar extraction and improving fermentation efficiency compared to natural mashing, which relies solely on the malt's inherent enzymes and can be slower and less consistent. Your brewing process benefits from added enzymes by achieving more predictable results, better flavor profiles, and higher alcohol yields.

Table of Comparison

| Aspect | Brewing Enzymes | Natural Mashing |

|---|---|---|

| Process Control | High precision and consistency | Variable based on grain quality and conditions |

| Conversion Efficiency | Rapid and complete starch breakdown | Slower enzymatic activity, less efficient |

| Flavor Profile | Neutral, allows flavor customization | Natural, traditional malt-derived flavors |

| Cost | Higher initial cost for enzymes | Lower cost using malted grains |

| Operational Flexibility | Flexible temperature and pH ranges | Requires strict temperature and pH control |

| Use Cases | Industrial-scale, specialty brewing | Traditional craft and small-scale brewing |

Introduction: Brewing Enzymes vs Natural Mashing

Brewing enzymes enhance starch breakdown by accelerating the conversion of complex carbohydrates into fermentable sugars, improving efficiency and consistency in beer production. Natural mashing relies on inherent malt enzymes and precise temperature control for starch conversion, yielding traditional flavor profiles and mouthfeel. Enzymatic supplementation allows brewers to optimize fermentation performance and tailor beer characteristics beyond the limitations of natural mashing.

Understanding Brewing Enzymes

Brewing enzymes play a crucial role in breaking down starches into fermentable sugars during the mashing process, increasing efficiency compared to natural mashing. Key enzymes such as alpha-amylase and beta-amylase target complex carbohydrates, optimizing sugar yield and improving beer consistency. Understanding enzyme activity and temperature ranges helps brewers control fermentation, enhancing flavor profile and alcohol content.

The Science Behind Natural Mashing

Natural mashing relies on the enzymatic activity inherent in malted grains, primarily amylases and proteases, to break down starches into fermentable sugars and proteins into amino acids, essential for yeast nutrition and beer quality. Unlike commercial brewing enzymes added to optimize conversions, natural mashing depends on precise temperature control between 62-72degC to activate these endogenous enzymes at peak efficiency. Understanding the biochemical mechanisms of natural mashing can enhance Your brewing outcomes by improving wort composition, flavor development, and fermentation performance.

Key Differences in Enzymatic Activity

Brewing enzymes offer precise control over enzymatic activity, enabling consistent starch breakdown and sugar extraction compared to natural mashing, which relies on variable native enzymes in malt. Enzymatic supplementation optimizes fermentation by targeting specific substrates, enhancing yield and flavor profiles, while natural mashing may result in incomplete conversion due to fluctuating enzyme concentrations. Your brewing process benefits from targeted enzymatic action that improves efficiency and allows for better adjustment to ingredient variability.

Efficiency and Yield: Enzymes vs Mashing

Brewing enzymes significantly enhance starch breakdown during mashing, increasing efficiency by accelerating conversion rates and improving fermentable sugar yield. Natural mashing relies on inherent malt enzymes, often resulting in slower and less complete starch conversion, which can lower overall extract efficiency. Using brewing enzymes allows you to achieve higher yield consistency and optimize your brewing throughput.

Flavor Impact: Enzymes Compared to Traditional Methods

Brewing enzymes enhance flavor profiles by breaking down starches and proteins more efficiently than natural mashing, resulting in cleaner, more consistent beer with subtle sweetness and improved mouthfeel. Traditional mashing relies on naturally occurring enzymes, often producing more complex and varied flavor notes but with less predictability. The targeted action of commercial enzymes allows brewers to tailor flavor characteristics and improve extraction rates, optimizing the overall sensory experience.

Cost Implications for Brewers

Brewing enzymes reduce the cost implications for brewers by accelerating the mashing process and improving starch conversion efficiency, which leads to higher yield and less raw material waste. Compared to natural mashing, enzyme use lowers energy consumption and shortens production time, directly impacting operating expenses. You can achieve consistent product quality with reduced variability, minimizing potential losses during fermentation and packaging stages.

Flexibility and Process Control

Brewing enzymes offer superior flexibility and process control compared to natural mashing by precisely targeting starch breakdown and optimizing sugar extraction. Enzymatic mashing allows for consistent temperature and pH adjustments, ensuring predictable fermentation outcomes and enhanced flavor profiles. Your brewing process benefits from reduced variability and increased efficiency when leveraging tailored enzyme formulations over traditional methods.

Sustainability and Environmental Considerations

Brewing enzymes significantly reduce water and energy consumption compared to natural mashing by accelerating starch conversion and improving extract yields, contributing to a more sustainable production process. These enzymes lower the need for prolonged heating and reduce waste generation, minimizing the brewery's environmental footprint. By incorporating enzyme technology, your brewery can enhance efficiency while supporting eco-friendly practices aligned with sustainability goals.

Choosing the Right Approach for Your Brew

Selecting the right brewing enzymes versus natural mashing depends on desired flavor complexity, fermentation efficiency, and control over the brewing process. Brewing enzymes enhance starch conversion and improve clarity, making them ideal for consistent, high-quality beer production, while natural mashing relies on malted barley's inherent enzymes to develop traditional flavors and textures. Evaluating factors such as grain type, brewing scale, and final product goals ensures optimal enzyme use or adherence to natural mashing techniques.

Brewing enzymes vs natural mashing Infographic

libmatt.com

libmatt.com