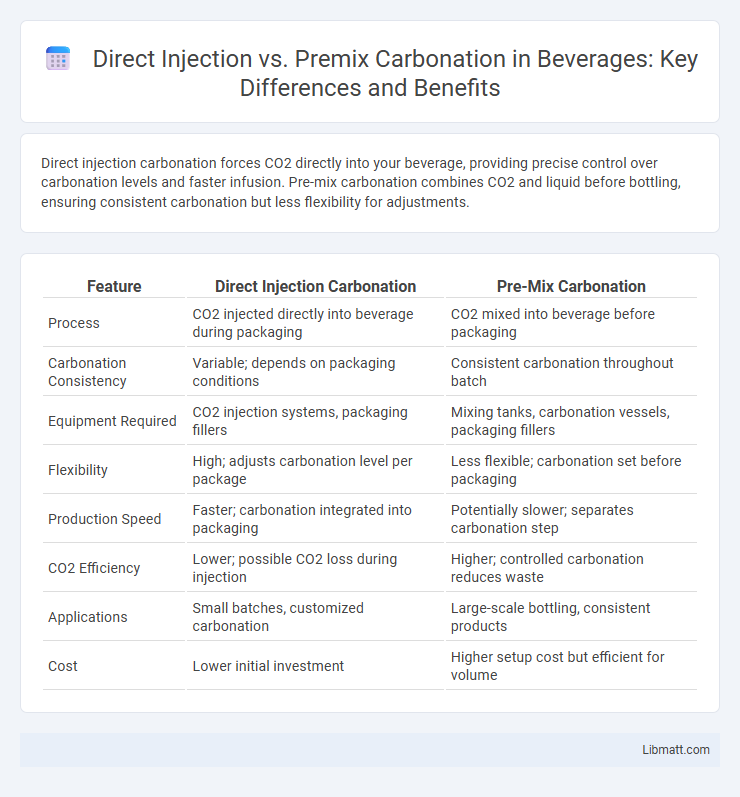

Direct injection carbonation forces CO2 directly into your beverage, providing precise control over carbonation levels and faster infusion. Pre-mix carbonation combines CO2 and liquid before bottling, ensuring consistent carbonation but less flexibility for adjustments.

Table of Comparison

| Feature | Direct Injection Carbonation | Pre-Mix Carbonation |

|---|---|---|

| Process | CO2 injected directly into beverage during packaging | CO2 mixed into beverage before packaging |

| Carbonation Consistency | Variable; depends on packaging conditions | Consistent carbonation throughout batch |

| Equipment Required | CO2 injection systems, packaging fillers | Mixing tanks, carbonation vessels, packaging fillers |

| Flexibility | High; adjusts carbonation level per package | Less flexible; carbonation set before packaging |

| Production Speed | Faster; carbonation integrated into packaging | Potentially slower; separates carbonation step |

| CO2 Efficiency | Lower; possible CO2 loss during injection | Higher; controlled carbonation reduces waste |

| Applications | Small batches, customized carbonation | Large-scale bottling, consistent products |

| Cost | Lower initial investment | Higher setup cost but efficient for volume |

Understanding Carbonation: Direct Injection vs Pre-Mix

Understanding carbonation methods involves comparing direct injection and pre-mix carbonation, two prominent techniques in beverage production. Direct injection infuses CO2 directly into the liquid, allowing precise control over carbonation levels and faster production times, ideal for custom carbonation needs. Pre-mix carbonation blends CO2 with the liquid prior to packaging, ensuring consistent carbonation throughout the product, commonly used for mass-produced carbonated beverages.

How Direct Injection Carbonation Works

Direct injection carbonation works by injecting carbon dioxide (CO2) directly into the liquid under high pressure, allowing rapid dissolution of the gas into the beverage. This method enhances carbonation efficiency and results in consistent bubble size and sensory quality. Unlike pre-mix carbonation, direct injection eliminates the need for premixing CO2 with water, streamlining the production process.

The Pre-Mix Carbonation Method Explained

The Pre-Mix Carbonation method involves blending carbon dioxide directly into the beverage before packaging, ensuring consistent carbonation levels throughout the liquid. This technique allows for precise control over the CO2 content, resulting in a uniform fizz and extended shelf life. If you are looking to maintain consistent carbonation in your products, pre-mix carbonation offers an efficient and reliable solution.

Key Differences Between Direct Injection and Pre-Mix

Direct injection carbonation involves injecting CO2 directly into the beverage during dispensing, allowing precise control over carbonation level and freshness. Pre-mix carbonation means that CO2 is mixed into the beverage beforehand, resulting in a consistent carbonation level throughout the container but limited adjustment at the point of serving. Key differences include control over carbonation, equipment complexity, and flexibility in serving, with direct injection offering more customization and pre-mix providing simplicity and uniformity.

Efficiency Comparison: Direct Injection vs Pre-Mix

Direct injection carbonation offers higher efficiency by injecting CO2 directly into the beverage, resulting in faster carbonation and reduced gas waste compared to pre-mix carbonation, which blends CO2 and liquid before packaging. Pre-mix carbonation can lead to inconsistent CO2 levels and potential overuse of gas, increasing operational costs. Direct injection systems optimize CO2 usage and provide precise control over carbonation levels, making them more cost-effective and environmentally sustainable solutions.

Cost Analysis: Which Carbonation Method Is Cheaper?

Direct injection carbonation typically incurs lower operational costs due to its efficient CO2 utilization and reduced energy consumption compared to pre-mix carbonation, which requires more complex equipment and longer processing times. Pre-mix carbonation involves blending CO2 with water before beverage mixing, often leading to higher initial setup expenses and ongoing maintenance costs. Your choice hinges on balancing these cost factors against production volume and desired carbonation consistency.

Impact on Beverage Quality and Taste

Direct injection carbonation dissolves CO2 directly into the beverage, producing a consistent, sharp effervescence that enhances flavor clarity and mouthfeel. Pre-mix carbonation involves carbonating the liquid before packaging, which can sometimes lead to uneven carbonation levels and a muted taste profile. Understanding these differences helps you choose the best method to maintain optimal beverage quality and desired taste characteristics.

Equipment and Maintenance Requirements

Direct injection carbonation requires specialized high-pressure gas injection equipment and sealed gas diffusers, demanding regular inspection and maintenance to prevent leaks and ensure consistent CO2 delivery. Pre-mix carbonation relies on blending CO2 with water in a controlled environment before dispensing, utilizing simpler equipment but necessitating routine calibration of mixing tanks and monitoring of gas-to-liquid ratios. Both systems benefit from scheduled cleaning protocols to avoid microbial growth and maintain carbonation quality.

Suitable Applications for Each Carbonation Method

Direct injection carbonation is ideal for small-scale or on-demand applications such as home soda makers and craft beverage production where precise CO2 control and rapid carbonation are needed. Pre-mix carbonation suits large-scale operations like bottling plants and commercial breweries, offering consistent carbonation levels by blending CO2 with the product before packaging. Each method's application depends on production volume, desired carbonation precision, and equipment complexity.

Choosing the Right Carbonation Method for Your Business

Direct injection carbonation offers precise CO2 control and faster carbonation rates, ideal for businesses requiring high volume and consistent quality. Pre-mix carbonation simplifies production by combining CO2 with the product beforehand, reducing equipment costs but limiting flexibility in carbonation levels. Selecting the right method depends on factors like production scale, product type, and desired carbonation consistency to optimize efficiency and customer satisfaction.

Direct injection vs pre-mix carbonation Infographic

libmatt.com

libmatt.com