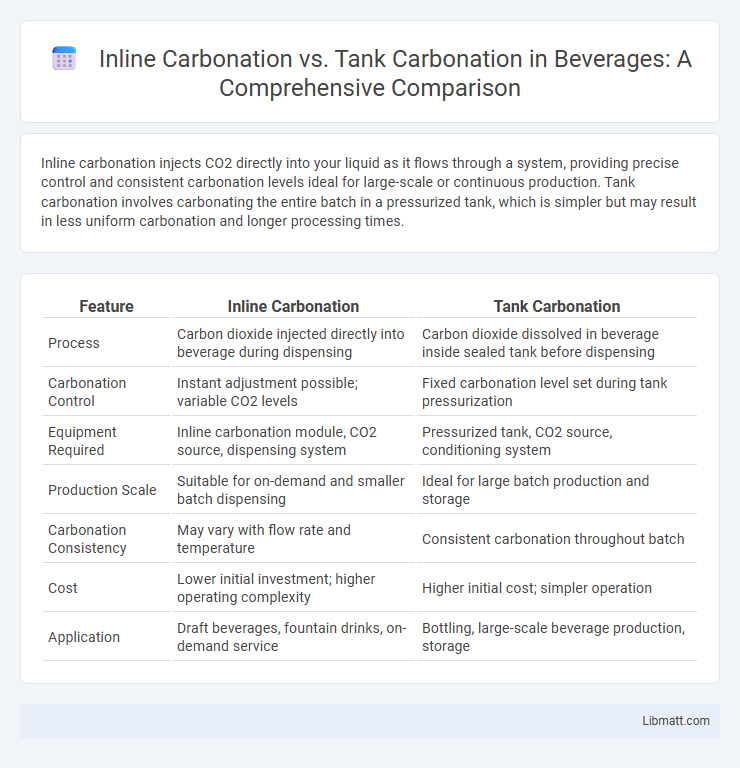

Inline carbonation injects CO2 directly into your liquid as it flows through a system, providing precise control and consistent carbonation levels ideal for large-scale or continuous production. Tank carbonation involves carbonating the entire batch in a pressurized tank, which is simpler but may result in less uniform carbonation and longer processing times.

Table of Comparison

| Feature | Inline Carbonation | Tank Carbonation |

|---|---|---|

| Process | Carbon dioxide injected directly into beverage during dispensing | Carbon dioxide dissolved in beverage inside sealed tank before dispensing |

| Carbonation Control | Instant adjustment possible; variable CO2 levels | Fixed carbonation level set during tank pressurization |

| Equipment Required | Inline carbonation module, CO2 source, dispensing system | Pressurized tank, CO2 source, conditioning system |

| Production Scale | Suitable for on-demand and smaller batch dispensing | Ideal for large batch production and storage |

| Carbonation Consistency | May vary with flow rate and temperature | Consistent carbonation throughout batch |

| Cost | Lower initial investment; higher operating complexity | Higher initial cost; simpler operation |

| Application | Draft beverages, fountain drinks, on-demand service | Bottling, large-scale beverage production, storage |

Introduction to Beer Carbonation Methods

Beer carbonation methods include inline carbonation and tank carbonation, each influencing beer quality and production efficiency. Inline carbonation injects precise amounts of CO2 directly into the beer during packaging, ensuring consistent carbonation levels and faster processing times. Tank carbonation involves carbonating beer in bulk within fermentation or bright tanks, allowing natural CO2 absorption but requiring longer maturation periods for optimal carbonation and flavor development.

What is Inline Carbonation?

Inline carbonation involves injecting CO2 directly into the liquid as it flows through a system, ensuring precise and consistent carbonation levels. This process reduces the need for large storage tanks, minimizes dissolved oxygen exposure, and enhances efficiency in beverage production. Your carbonated products achieve improved taste and stability thanks to this controlled, real-time carbonation method.

What is Tank Carbonation?

Tank carbonation is a process where carbon dioxide is infused directly into a beverage stored in a sealed tank, ensuring consistent carbonation levels throughout the batch. This method allows for precise control of CO2 pressure and contact time, resulting in uniform fizziness and improved flavor retention. Tank carbonation is commonly used in breweries and soda production for efficient large-scale carbonation before packaging.

Key Differences Between Inline and Tank Carbonation

Inline carbonation injects CO2 directly into the liquid as it flows through the system, ensuring continuous and consistent carbonation levels, while tank carbonation carbonates the liquid in a sealed tank before distribution, allowing for better control over carbonation intensity. Inline systems offer faster carbonation and are ideal for high-volume production, whereas tank carbonation provides flexibility in adjusting CO2 levels during storage. Your choice depends on production scale and specific carbonation consistency requirements.

Equipment Required for Each Method

Inline carbonation requires specialized equipment such as a carbonation injector or inline carbonator that integrates directly into the beverage production line, utilizing CO2 injectors and flow meters to ensure precise gas infusion. Tank carbonation involves the use of pressurized tanks or carbonation vessels where CO2 is infused under controlled pressure and temperature before packaging, often requiring agitators or mixers to enhance gas absorption. Your choice depends on production scale and desired carbonation control, with inline systems offering continuous, real-time carbonation and tank methods allowing batch-specific control.

Efficiency and Time Considerations

Inline carbonation delivers CO2 directly into the beverage flow, significantly reducing carbonation time and enhancing overall process efficiency compared to tank carbonation, which requires pre-filling and pressurizing the tank. This method minimizes CO2 wastage and allows for on-demand carbonation, making it ideal for high-volume production with faster turnaround. Your operation benefits from streamlined workflow and consistent quality by choosing inline carbonation over traditional tank methods.

Impact on Flavor and Beer Quality

Inline carbonation offers precise control over CO2 levels, resulting in consistent carbonation that preserves the beer's intended flavor profile and mouthfeel. Tank carbonation allows for natural absorption of CO2 during conditioning, which can enhance beer quality by promoting smoother, more integrated carbonation and subtle flavor development. Your choice between these methods directly impacts the balance and freshness of your final beer.

Cost Comparison of Inline vs Tank Carbonation

Inline carbonation systems typically involve higher initial costs due to advanced equipment and installation requirements, but they offer greater efficiency and lower operational expenses over time. Tank carbonation requires lower upfront investment with simpler setups, yet it can lead to increased maintenance and slower production rates, potentially raising long-term costs. Your choice depends on balancing immediate budget constraints against anticipated throughput and efficiency gains.

Choosing the Right Carbonation Method

Choosing the right carbonation method depends on your production scale and desired control over carbonation levels. Inline carbonation offers precise, real-time CO2 injection directly into the beverage line, ideal for consistent, high-volume output. Tank carbonation involves infusing CO2 into a sealed tank, providing simplicity and cost-effectiveness for smaller batches or less time-sensitive processes.

Conclusion: Inline vs Tank Carbonation

Inline carbonation delivers precise CO2 mixing by integrating directly with the beverage line, ensuring consistent carbonation levels and reducing oxygen exposure. Tank carbonation offers simpler setup with bulk gas infusion but may result in less uniform carbonation and increased risk of overcarbonation or flavor variation. For scalable, consistent beverage production, inline carbonation is typically preferred over tank carbonation.

Inline carbonation vs tank carbonation Infographic

libmatt.com

libmatt.com