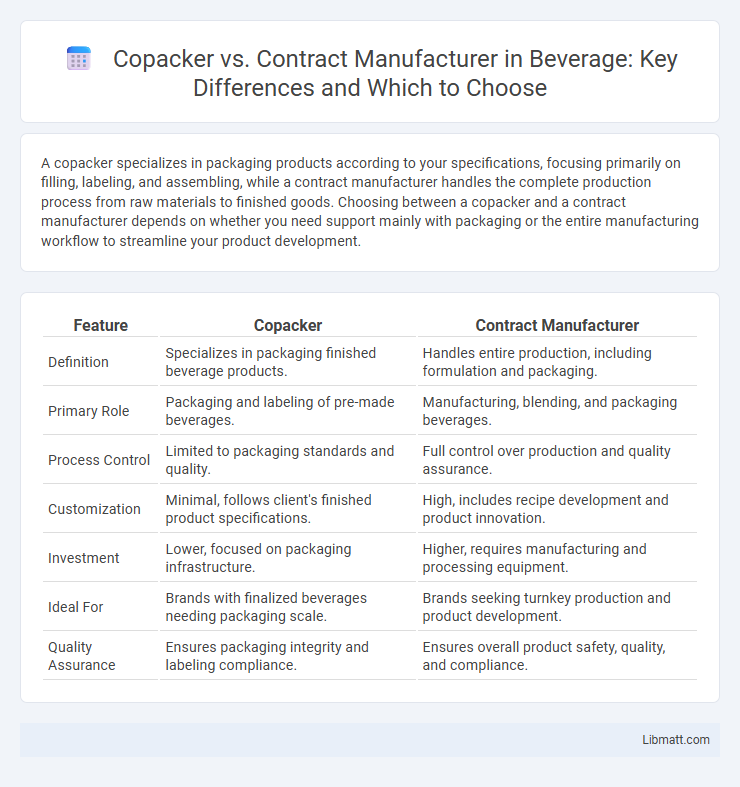

A copacker specializes in packaging products according to your specifications, focusing primarily on filling, labeling, and assembling, while a contract manufacturer handles the complete production process from raw materials to finished goods. Choosing between a copacker and a contract manufacturer depends on whether you need support mainly with packaging or the entire manufacturing workflow to streamline your product development.

Table of Comparison

| Feature | Copacker | Contract Manufacturer |

|---|---|---|

| Definition | Specializes in packaging finished beverage products. | Handles entire production, including formulation and packaging. |

| Primary Role | Packaging and labeling of pre-made beverages. | Manufacturing, blending, and packaging beverages. |

| Process Control | Limited to packaging standards and quality. | Full control over production and quality assurance. |

| Customization | Minimal, follows client's finished product specifications. | High, includes recipe development and product innovation. |

| Investment | Lower, focused on packaging infrastructure. | Higher, requires manufacturing and processing equipment. |

| Ideal For | Brands with finalized beverages needing packaging scale. | Brands seeking turnkey production and product development. |

| Quality Assurance | Ensures packaging integrity and labeling compliance. | Ensures overall product safety, quality, and compliance. |

Introduction to Copackers and Contract Manufacturers

Copackers specialize in packaging products according to your brand specifications, often handling small to medium production runs with flexibility and speed. Contract manufacturers focus on producing the entire product, from raw materials to finished goods, usually managing large-scale production and complex manufacturing processes. Understanding the distinction helps in choosing the best partner tailored to your production needs.

Defining Copackers: What Do They Do?

Copackers specialize in packaging products on behalf of brands, handling tasks such as filling, labeling, and boxing to streamline your supply chain. Unlike contract manufacturers who produce goods from raw materials, copackers focus primarily on the final stages of product preparation for market. This distinction allows companies to scale packaging operations efficiently without investing in additional manufacturing infrastructure.

Contract Manufacturers Explained

Contract manufacturers are specialized companies that produce goods on behalf of a brand or company, handling the manufacturing process based on provided specifications and designs. They offer comprehensive production capabilities, including sourcing raw materials, managing labor, and ensuring quality control, allowing brands to focus on marketing and product development. Unlike copackers, contract manufacturers often engage in more complex manufacturing tasks beyond just packaging, covering the entire production lifecycle.

Key Differences Between Copackers and Contract Manufacturers

Copackers specialize in packaging products according to client specifications, often handling tasks like filling, labeling, and sealing, whereas contract manufacturers are involved in the entire production process, including sourcing raw materials, manufacturing, and assembling finished goods. Copackers typically provide flexibility for smaller batch sizes and focus on product presentation, while contract manufacturers emphasize large-scale production efficiency and process optimization. Understanding these distinctions helps businesses choose the right partner based on their production needs, budget constraints, and quality control requirements.

Pros and Cons of Copackers

Copackers offer the advantage of specialized packaging expertise and the ability to scale production quickly without investing in new equipment, making them ideal for businesses seeking efficient, cost-effective fulfillment solutions. You benefit from reduced operational complexity and faster time-to-market, but copackers may limit control over product quality and confidentiality compared to contract manufacturers who often manage the entire production process. Relying on a copacker also poses risks such as less flexibility in customization and potential dependency on a third party's scheduling and capacity.

Pros and Cons of Contract Manufacturers

Contract manufacturers offer scalability and access to specialized production expertise, reducing capital investment and speeding up time-to-market. However, they may pose risks such as less control over quality, intellectual property concerns, and potential communication challenges. Companies must weigh these factors carefully to align outsourcing with their strategic goals and maintain product integrity.

How to Choose: Factors to Consider

Choosing between a copacker and a contract manufacturer involves evaluating production scale, specialization, and customization needs. Your decision should consider factors like volume requirements, packaging complexity, quality control standards, and lead times to ensure alignment with your product goals. Assessing their expertise, equipment capabilities, and cost structures helps determine which partner can best support your brand's manufacturing and packaging processes.

Cost Comparison: Copackers vs Contract Manufacturers

Copackers typically offer lower upfront costs due to their streamlined processes and smaller production runs, making them ideal for startups and small brands. Contract manufacturers often require higher minimum order quantities and larger capital investments, resulting in greater initial expenses but lower cost per unit at scale. Your choice depends on production volume and budget constraints, balancing affordability with long-term manufacturing efficiency.

Industry Applications and Suitability

Copackers excel in industries like food, cosmetics, and supplements where flexible packaging and small batch production are essential, offering tailored solutions for startups and niche brands. Contract manufacturers are suited for large-scale industries such as pharmaceuticals, electronics, and automotive, providing extensive regulatory compliance and mass production capabilities. Your choice depends on the specific volume, regulatory requirements, and customization level needed for your product's industry application.

Final Thoughts: Which Option is Right for Your Business?

Choosing between a copacker and a contract manufacturer depends on your business's production scale, control preferences, and customization needs. Copackers are ideal for companies seeking streamlined packaging and smaller batch production without investing in their own facilities. Contract manufacturers suit businesses requiring full-scale production with specialized process control and product development capabilities.

Copacker vs contract manufacturer Infographic

libmatt.com

libmatt.com