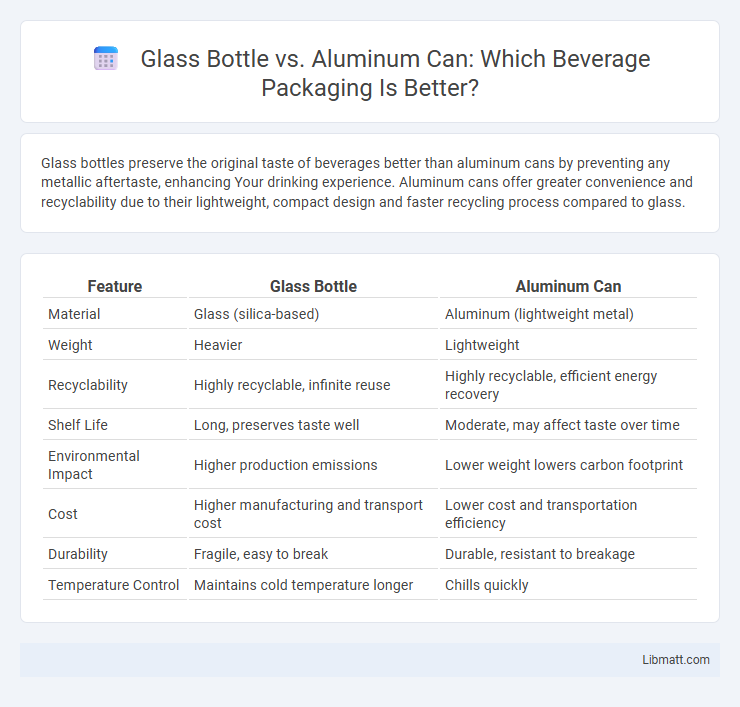

Glass bottles preserve the original taste of beverages better than aluminum cans by preventing any metallic aftertaste, enhancing Your drinking experience. Aluminum cans offer greater convenience and recyclability due to their lightweight, compact design and faster recycling process compared to glass.

Table of Comparison

| Feature | Glass Bottle | Aluminum Can |

|---|---|---|

| Material | Glass (silica-based) | Aluminum (lightweight metal) |

| Weight | Heavier | Lightweight |

| Recyclability | Highly recyclable, infinite reuse | Highly recyclable, efficient energy recovery |

| Shelf Life | Long, preserves taste well | Moderate, may affect taste over time |

| Environmental Impact | Higher production emissions | Lower weight lowers carbon footprint |

| Cost | Higher manufacturing and transport cost | Lower cost and transportation efficiency |

| Durability | Fragile, easy to break | Durable, resistant to breakage |

| Temperature Control | Maintains cold temperature longer | Chills quickly |

Introduction to Glass Bottles and Aluminum Cans

Glass bottles offer superior chemical inertness, preserving beverage flavor without interaction or leaching, while aluminum cans excel in lightweight durability and recyclability, promoting efficient transportation and reduced environmental impact. Both packaging types provide effective barriers against oxygen and light, but glass bottles typically ensure longer shelf life due to their impermeability and resistance to oxidation. The choice between glass and aluminum depends on factors such as product type, sustainability goals, and consumer preference for tactile experience or convenience.

Environmental Impact Comparison

Glass bottles have a higher carbon footprint due to energy-intensive production and transportation compared to aluminum cans, which are lighter and more efficient to ship. Aluminum cans excel in recyclability, as they can be recycled indefinitely with lower energy consumption, while glass recycling is less efficient and often downcycles. Your choice impacts resource use and waste management, making aluminum cans a more sustainable option overall for reducing environmental impact.

Manufacturing Processes and Resources Used

Glass bottle manufacturing relies heavily on silica sand, soda ash, and limestone, which are melted at high temperatures in furnaces consuming significant energy. Aluminum cans are produced through bauxite mining, refined to alumina, then smelted to pure aluminum using an energy-intensive electrolytic process. Both involve resource extraction and high energy usage, but aluminum recycling requires substantially less energy compared to primary production, improving its sustainability profile.

Recyclability and Sustainability

Glass bottles offer high recyclability with the ability to be recycled indefinitely without quality loss, supporting circular economy goals and reducing resource extraction. Aluminum cans are also highly recyclable, with about 75% of all aluminum ever produced still in use, and their recycling process saves up to 95% of the energy required for new aluminum production. Both materials contribute to sustainability, but aluminum's lightweight nature reduces transportation emissions, while glass's inert composition avoids chemical contamination in recycling streams.

Packaging and Preservation of Contents

Glass bottles provide superior preservation of contents due to their impermeability and inert nature, preventing flavor alteration and ensuring longer shelf life. Aluminum cans offer excellent protection from light and oxygen, crucial for maintaining effervescence and freshness in beverages. Choosing between glass and aluminum for your packaging depends on factors like product sensitivity, storage conditions, and environmental impact preferences.

Health and Safety Considerations

Glass bottles are generally considered safer for health as they do not leach chemicals into beverages, unlike some aluminum cans that may contain BPA or other harmful linings. Glass is non-reactive and maintains the purity of contents, reducing risks of contamination and taste alteration. However, glass poses safety hazards due to breakability, whereas aluminum cans offer a lightweight, shatterproof alternative with a lower injury risk during handling and transport.

Cost Analysis for Producers and Consumers

Glass bottles generally incur higher production and transportation costs due to their weight and fragility, leading to increased shipping expenses for producers. Aluminum cans often present cost savings through lower material and recycling expenses, benefiting both manufacturers and consumers with typically lower retail prices. Your choice between glass and aluminum can impact expenses, balancing environmental preferences against upfront and long-term costs.

Consumer Preferences and Market Trends

Consumer preferences show a growing shift toward aluminum cans due to their lightweight, recyclability, and convenience, particularly among younger demographics seeking portable beverage options. Glass bottles maintain a strong presence in premium and craft beverage markets, favored for preserving taste quality and perceived environmental benefits. Your choice may depend on whether you prioritize sustainability credentials, aesthetic appeal, or convenience as market trends continue to evolve.

Transportation and Storage Efficiency

Glass bottles have a higher weight and fragility compared to aluminum cans, resulting in increased transportation costs and more careful handling requirements. Aluminum cans are lightweight, stackable, and more compact, optimizing storage space and reducing shipping expenses. These factors make aluminum cans more efficient for large-scale distribution and logistics.

Future Trends in Beverage Packaging

Future trends in beverage packaging emphasize sustainability, driving innovation in both glass bottles and aluminum cans. Glass bottles are advancing with lightweight designs and enhanced recyclability, appealing to eco-conscious consumers seeking premium experiences. Aluminum cans lead in recyclability rates and are adopting smart technology for improved supply chain tracking and personalized marketing.

Glass bottle vs aluminum can Infographic

libmatt.com

libmatt.com