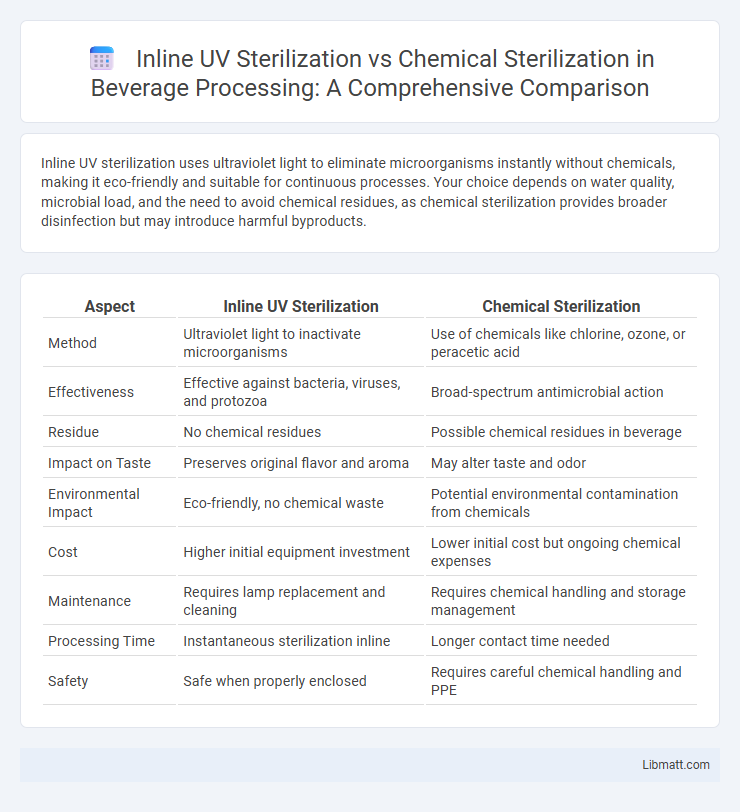

Inline UV sterilization uses ultraviolet light to eliminate microorganisms instantly without chemicals, making it eco-friendly and suitable for continuous processes. Your choice depends on water quality, microbial load, and the need to avoid chemical residues, as chemical sterilization provides broader disinfection but may introduce harmful byproducts.

Table of Comparison

| Aspect | Inline UV Sterilization | Chemical Sterilization |

|---|---|---|

| Method | Ultraviolet light to inactivate microorganisms | Use of chemicals like chlorine, ozone, or peracetic acid |

| Effectiveness | Effective against bacteria, viruses, and protozoa | Broad-spectrum antimicrobial action |

| Residue | No chemical residues | Possible chemical residues in beverage |

| Impact on Taste | Preserves original flavor and aroma | May alter taste and odor |

| Environmental Impact | Eco-friendly, no chemical waste | Potential environmental contamination from chemicals |

| Cost | Higher initial equipment investment | Lower initial cost but ongoing chemical expenses |

| Maintenance | Requires lamp replacement and cleaning | Requires chemical handling and storage management |

| Processing Time | Instantaneous sterilization inline | Longer contact time needed |

| Safety | Safe when properly enclosed | Requires careful chemical handling and PPE |

Introduction to Water Sterilization Methods

Inline UV sterilization uses ultraviolet light to inactivate microorganisms in water, providing a chemical-free and eco-friendly approach to disinfection. Chemical sterilization, such as chlorination or ozone treatment, relies on chemical agents to kill or deactivate pathogens but may introduce residual chemicals or by-products. Selecting the appropriate water sterilization method depends on factors like water quality, regulatory standards, and desired microbial control efficiency.

Overview of Inline UV Sterilization

Inline UV sterilization uses ultraviolet light to eliminate microorganisms in fluids or air as they flow through a system, providing continuous and chemical-free disinfection. This method offers effective microbial control without introducing harmful residues or altering product qualities, making it ideal for water treatment, beverage processing, and pharmaceutical applications. Its efficiency depends on factors such as UV intensity, exposure time, and fluid clarity to ensure complete sterilization.

Chemical Sterilization: Common Approaches

Chemical sterilization commonly employs agents such as ethylene oxide, hydrogen peroxide vapor, and formaldehyde to eliminate microorganisms on medical equipment and surfaces. These methods rely on the chemical reaction between sterilants and microbial cells to disrupt cellular processes, effectively neutralizing bacteria, viruses, and spores. Despite their efficacy, chemical sterilants require careful handling, specific concentration, and exposure time to ensure safety and avoid material compatibility issues.

Mechanisms of Action: UV vs Chemicals

Inline UV sterilization employs ultraviolet light at specific wavelengths, primarily UV-C (around 254 nm), to disrupt the DNA and RNA of microorganisms, rendering them incapable of replication and effectively inactivating bacteria, viruses, and protozoa. Chemical sterilization relies on reactive agents such as chlorine, ozone, or hydrogen peroxide, which chemically oxidize cellular components, proteins, and lipids, leading to microbial cell damage, denaturation, and death. While UV sterilization acts through photonic disruption of genetic material, chemical sterilization achieves microbial inactivation through molecular oxidation and damage to cellular structures.

Effectiveness Against Pathogens

Inline UV sterilization effectively targets and eliminates a broad spectrum of pathogens, including bacteria, viruses, and protozoa, by disrupting their DNA and preventing replication. Chemical sterilization, while potent against many microorganisms, can sometimes leave harmful residues and may be less effective against certain resistant spores or biofilms. Choosing the right method depends on your specific microbial challenges and safety requirements for the environment or product being sterilized.

Impact on Water Quality and Taste

Inline UV sterilization preserves water quality by effectively eliminating pathogens without introducing chemicals, ensuring the water maintains its natural taste and clarity. Chemical sterilization often alters water's flavor and odor due to residual disinfectants like chlorine, which can produce unpleasant tastes and potential byproducts. Choosing inline UV sterilization protects your water's purity and sensory characteristics without compromising safety or taste.

Environmental and Health Considerations

Inline UV sterilization reduces chemical waste and minimizes environmental pollution by avoiding harmful disinfectant byproducts commonly associated with chemical sterilization methods. It significantly lowers health risks for workers and consumers by eliminating exposure to toxic chemicals like chlorine and formaldehyde. UV sterilization offers a safer, eco-friendly alternative that preserves water quality and supports sustainable sterilization practices.

Installation and Maintenance Requirements

Inline UV sterilization systems require compact installation within water lines, with minimal space and no chemical storage, enabling easy integration into existing plumbing; maintenance mainly involves periodic UV lamp replacement and cleaning of quartz sleeves to ensure optimal performance. Chemical sterilization demands more complex infrastructure, including storage tanks, dosing pumps, and safety measures for handling hazardous chemicals, leading to higher installation costs and regulatory compliance challenges. Frequent monitoring and replenishment of chemical agents are necessary, increasing operational maintenance compared to the relatively low upkeep of UV systems.

Cost Comparison: Upfront and Long-Term

Inline UV sterilization typically involves higher upfront costs due to the purchase and installation of UV lamps and specialized equipment, while chemical sterilization requires ongoing expenses for disinfectant chemicals and storage. Over the long term, UV sterilization tends to be more cost-effective as it reduces recurring chemical purchases and waste disposal fees. Maintenance for UV systems primarily includes periodic bulb replacement and cleaning, whereas chemical sterilization demands continuous supply management and regulatory compliance costs.

Choosing the Right Sterilization Method

Choosing the right sterilization method depends on factors like the type of microorganisms, material compatibility, and process efficiency. Inline UV sterilization offers rapid, chemical-free microbial control ideal for water, air, and transparent surfaces, while chemical sterilization provides broad-spectrum efficacy for complex equipment and surfaces resistant to UV light. Your decision should balance safety, application requirements, and operational costs to ensure optimal sterilization outcomes.

Inline UV sterilization vs chemical sterilization Infographic

libmatt.com

libmatt.com