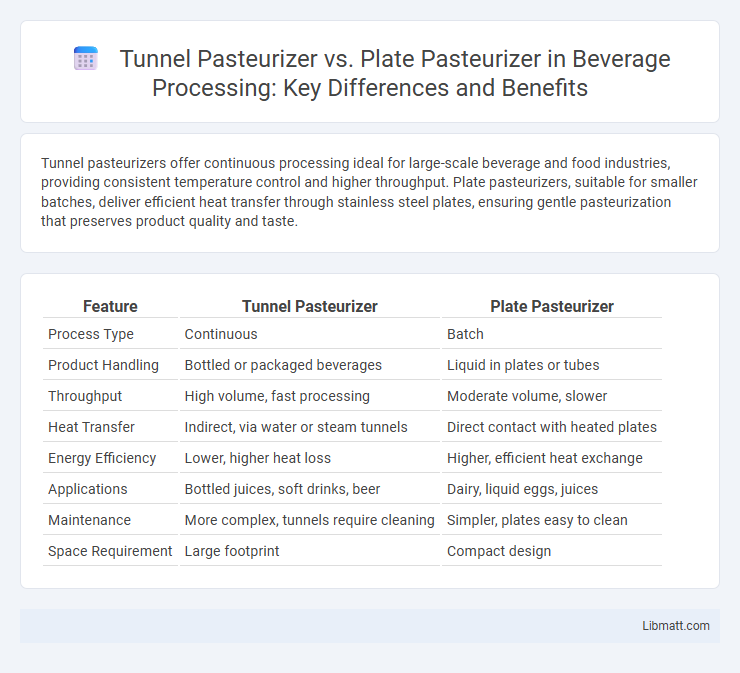

Tunnel pasteurizers offer continuous processing ideal for large-scale beverage and food industries, providing consistent temperature control and higher throughput. Plate pasteurizers, suitable for smaller batches, deliver efficient heat transfer through stainless steel plates, ensuring gentle pasteurization that preserves product quality and taste.

Table of Comparison

| Feature | Tunnel Pasteurizer | Plate Pasteurizer |

|---|---|---|

| Process Type | Continuous | Batch |

| Product Handling | Bottled or packaged beverages | Liquid in plates or tubes |

| Throughput | High volume, fast processing | Moderate volume, slower |

| Heat Transfer | Indirect, via water or steam tunnels | Direct contact with heated plates |

| Energy Efficiency | Lower, higher heat loss | Higher, efficient heat exchange |

| Applications | Bottled juices, soft drinks, beer | Dairy, liquid eggs, juices |

| Maintenance | More complex, tunnels require cleaning | Simpler, plates easy to clean |

| Space Requirement | Large footprint | Compact design |

Introduction to Pasteurization in Food Processing

Tunnel pasteurizers offer continuous processing by moving packaged products through heated zones, ensuring consistent heat treatment ideal for large-scale food production. Plate pasteurizers utilize heat exchange plates for rapid heating and cooling of liquid products, providing precise temperature control suitable for dairy and beverage industries. Your choice depends on the product form and volume, with tunnel systems favoring packaged or solid foods and plate systems optimized for fluids.

What is a Tunnel Pasteurizer?

A tunnel pasteurizer is an industrial machine designed for continuous pasteurization of bottled or packaged beverages, using controlled hot water or steam to eliminate harmful microorganisms while preserving product quality. It operates by moving products on a conveyor through a long, temperature-regulated tunnel, allowing precise control over pasteurization time and temperature. Compared to plate pasteurizers, which use heat exchange plates for batch processing, tunnel pasteurizers offer higher throughput and efficiency, making them ideal for large-scale production lines where uniform heat treatment is essential for your product's safety and shelf life.

What is a Plate Pasteurizer?

A plate pasteurizer uses a series of stainless steel plates to heat and cool liquid products rapidly through heat exchange, ensuring efficient pasteurization with minimal thermal degradation. It is ideal for processing dairy, juice, and other beverages requiring precise temperature control and high throughput. Compared to tunnel pasteurizers, plate pasteurizers provide faster processing times and uniform heating, making them suitable for liquid products with consistent flow rates.

Key Differences Between Tunnel and Plate Pasteurizers

Tunnel pasteurizers continuously process products by moving them on a conveyor through a heated tunnel, ensuring uniform pasteurization for high volumes. Plate pasteurizers use parallel metal plates to transfer heat to liquid products, suitable for smaller batch sizes with precise temperature control. Your choice depends on production scale and product type, as tunnel pasteurizers excel in speed and efficiency, while plate pasteurizers offer compact design and easy cleaning.

Advantages of Tunnel Pasteurizers

Tunnel pasteurizers offer continuous processing, ensuring high throughput and consistent product quality for beverages and liquid foods. Their energy efficiency and precise temperature control reduce thermal degradation while improving pathogen elimination. Compared to plate pasteurizers, tunnel systems accommodate larger volumes, making them ideal for high-capacity production lines.

Advantages of Plate Pasteurizers

Plate pasteurizers offer superior temperature control and uniform heating, minimizing the risk of uneven pasteurization and preserving the quality of your product. Their compact design requires less floor space compared to tunnel pasteurizers, making them ideal for smaller production facilities. Maintenance and cleaning processes are more straightforward, reducing downtime and operational costs.

Efficiency and Throughput Comparison

Tunnel pasteurizers offer higher throughput by processing large volumes of bottled or canned products continuously, making them ideal for high-capacity production lines. Plate pasteurizers provide precise temperature control with quicker heat exchange, resulting in better efficiency for small to medium batch sizes. You should choose tunnel pasteurizers for maximizing output, while plate pasteurizers are optimal for energy savings and consistency in smaller-scale operations.

Application Suitability: When to Use Each Pasteurizer

Tunnel pasteurizers are ideal for high-volume beverage production lines, efficiently handling glass or plastic bottles through continuous pasteurization, making them suitable for large-scale breweries and soft drink manufacturers. Plate pasteurizers best serve small to medium-sized operations requiring precise temperature control and flexibility, often used for dairy products, juices, and liquid eggs in batch or semi-continuous processes. Your choice depends on production scale and product type, with tunnel pasteurizers favored for bottling efficiency and plate pasteurizers for versatility in heat-sensitive products.

Cost Considerations: Investment and Operational Expenses

Tunnel pasteurizers generally involve higher initial investment costs due to their larger size and more complex automated systems, suitable for high-capacity production lines. Operational expenses for tunnel pasteurizers can be lower per unit as they optimize energy use and maintain continuous processing, resulting in cost efficiency at scale. Plate pasteurizers require less upfront capital, making them ideal for smaller operations, but their batch processing leads to higher energy and labor costs per unit, impacting long-term operational expenses.

Choosing the Right Pasteurizer for Your Production Needs

Tunnel pasteurizers provide continuous processing ideal for high-volume beverage lines, ensuring consistent temperature control and efficient pasteurization. Plate pasteurizers offer precise heat exchange solutions suitable for smaller batches or products sensitive to heat, optimizing your energy usage and product quality. Selecting the right pasteurizer depends on your production scale, product type, and desired throughput to maximize efficiency and maintain safety standards.

Tunnel pasteurizer vs plate pasteurizer Infographic

libmatt.com

libmatt.com