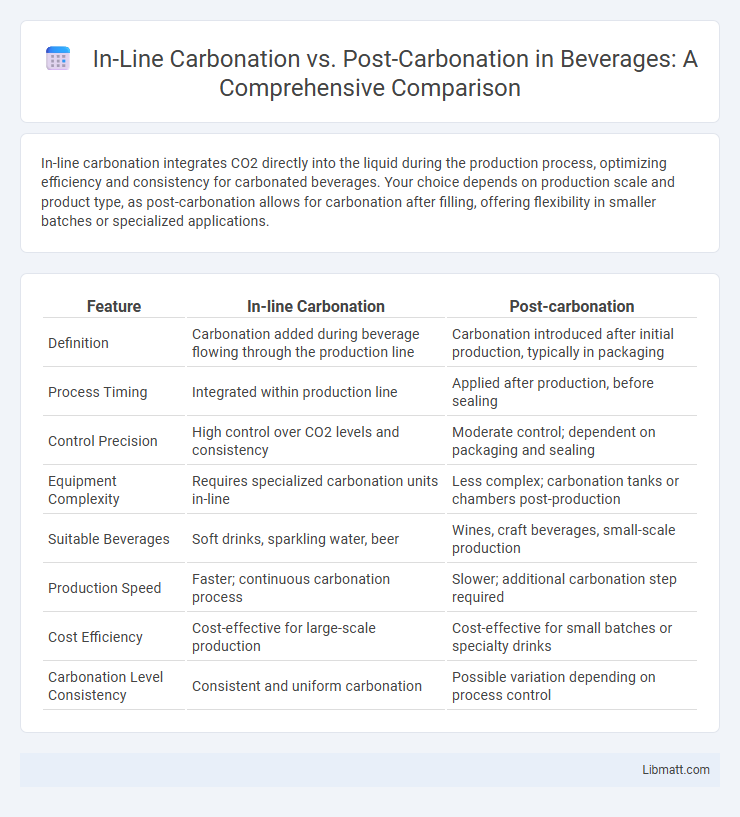

In-line carbonation integrates CO2 directly into the liquid during the production process, optimizing efficiency and consistency for carbonated beverages. Your choice depends on production scale and product type, as post-carbonation allows for carbonation after filling, offering flexibility in smaller batches or specialized applications.

Table of Comparison

| Feature | In-line Carbonation | Post-carbonation |

|---|---|---|

| Definition | Carbonation added during beverage flowing through the production line | Carbonation introduced after initial production, typically in packaging |

| Process Timing | Integrated within production line | Applied after production, before sealing |

| Control Precision | High control over CO2 levels and consistency | Moderate control; dependent on packaging and sealing |

| Equipment Complexity | Requires specialized carbonation units in-line | Less complex; carbonation tanks or chambers post-production |

| Suitable Beverages | Soft drinks, sparkling water, beer | Wines, craft beverages, small-scale production |

| Production Speed | Faster; continuous carbonation process | Slower; additional carbonation step required |

| Cost Efficiency | Cost-effective for large-scale production | Cost-effective for small batches or specialty drinks |

| Carbonation Level Consistency | Consistent and uniform carbonation | Possible variation depending on process control |

Introduction to Carbonation Methods

In-line carbonation integrates carbon dioxide directly into liquid during the production process, ensuring uniform gas distribution and rapid dissolution. Post-carbonation injects CO2 after the liquid has been fully processed, allowing precise control over carbonation levels and minimizing product oxidation. Both methods influence beverage texture, shelf life, and flavor stability, making them critical in beverage manufacturing and quality control.

What is In-line Carbonation?

In-line carbonation is a process where carbon dioxide is injected directly into the beverage during production, allowing immediate mixing and consistent carbonation levels throughout the product. This method ensures precise control over carbonation, optimizing product quality and shelf life. In-line carbonation is commonly used in large-scale beverage manufacturing for efficiency and uniformity.

What is Post-Carbonation?

Post-carbonation is the process of injecting carbon dioxide (CO2) into a fully brewed beverage, such as beer or soda, after fermentation or mixing. This method allows greater control over carbonation levels and consistency, ensuring the desired fizziness without affecting flavor development during brewing. It contrasts with in-line carbonation, which blends CO2 directly into the liquid during production for immediate carbonation.

Equipment Requirements for Each Method

In-line carbonation requires specialized equipment that integrates directly into the production line, including precision gas injection valves and flow meters for real-time CO2 control. Post-carbonation relies on separate carbonation tanks or pressure vessels where CO2 is injected after the initial product formulation, necessitating robust pressure regulators and mixing systems. The choice between methods impacts the complexity and cost of the carbonation system, influencing production speed and consistency.

Differences in Process Workflow

In-line carbonation integrates CO2 infusion directly into the production line, allowing real-time carbon dioxide dissolution as the liquid flows through the system, which results in a streamlined and continuous process. Post-carbonation occurs after the main production phase, where CO2 is injected into the beverage in a separate step, often in tanks or bottles, leading to a batch-based workflow. The primary difference in process workflow lies in the timing and method of carbonation application: in-line carbonation enhances efficiency with immediate gas dissolution, while post-carbonation provides greater control over carbonation levels in discrete production stages.

Impact on Beverage Quality and Consistency

In-line carbonation integrates CO2 directly during the mixing process, ensuring uniform gas dissolution and consistent carbonation levels throughout the beverage batch, which enhances overall quality. Post-carbonation adds CO2 after blending, potentially leading to inconsistent carbonation and variability in mouthfeel due to uneven gas absorption. In-line carbonation systems typically provide better control over dissolved CO2 pressure and temperature, resulting in superior beverage clarity and taste stability.

Efficiency and Production Speed

In-line carbonation integrates CO2 directly during the liquid filling process, significantly enhancing production speed by eliminating separate carbonation steps. This method ensures higher efficiency through precise CO2 dosage control, reducing gas wastage and improving product consistency. Conversely, post-carbonation requires additional carbonation tanks, increasing production time and energy consumption, which can slow overall throughput and lower operational efficiency.

Cost Comparison: In-line vs Post-Carbonation

In-line carbonation typically incurs lower operational costs due to its integration within the production line, reducing the need for additional equipment and energy consumption. Post-carbonation systems may require separate tanks and increased maintenance, leading to higher capital and operational expenses. You can optimize your beverage production budget by choosing in-line carbonation for cost efficiency in high-volume processes.

Applications and Industry Preferences

In-line carbonation is widely preferred in beverage manufacturing for its ability to integrate carbonation directly into the production line, enhancing efficiency in industries like soft drinks, beer, and sparkling water. Post-carbonation is often utilized in breweries and craft beverage producers where precise control over carbonation levels is essential for product quality and flavor profile. Food and beverage industries favor in-line carbonation for high-volume, continuous processes, while niche markets with smaller batches tend to opt for post-carbonation due to its flexibility.

Choosing the Right Carbonation Method

Choosing the right carbonation method depends on production scale, beverage type, and desired carbonation control. In-line carbonation offers precise CO2 control during mixing, reducing oxygen exposure and enhancing flavor stability, ideal for large-scale automated processes. Post-carbonation, applied after packaging, suits smaller batches or products requiring gentler carbonation, preserving delicate flavors in craft beverages.

In-line carbonation vs post-carbonation Infographic

libmatt.com

libmatt.com