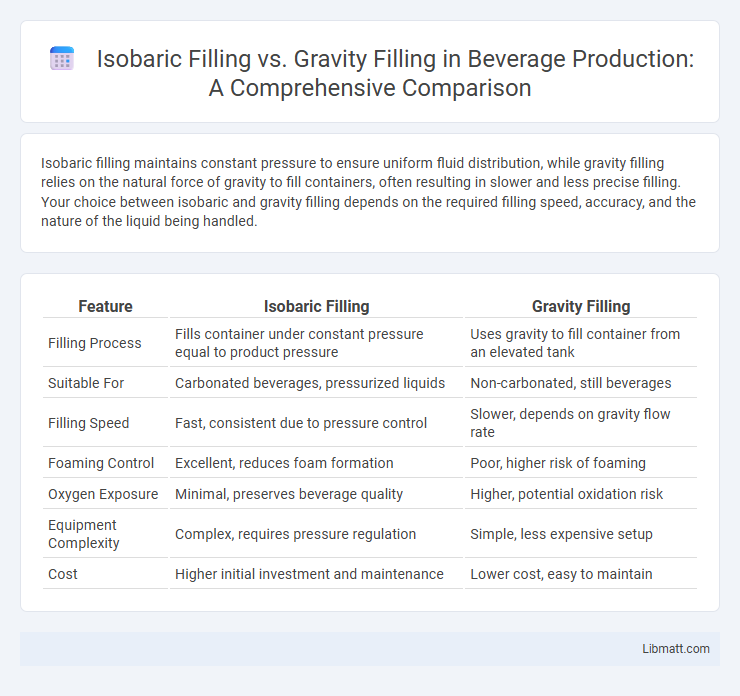

Isobaric filling maintains constant pressure to ensure uniform fluid distribution, while gravity filling relies on the natural force of gravity to fill containers, often resulting in slower and less precise filling. Your choice between isobaric and gravity filling depends on the required filling speed, accuracy, and the nature of the liquid being handled.

Table of Comparison

| Feature | Isobaric Filling | Gravity Filling |

|---|---|---|

| Filling Process | Fills container under constant pressure equal to product pressure | Uses gravity to fill container from an elevated tank |

| Suitable For | Carbonated beverages, pressurized liquids | Non-carbonated, still beverages |

| Filling Speed | Fast, consistent due to pressure control | Slower, depends on gravity flow rate |

| Foaming Control | Excellent, reduces foam formation | Poor, higher risk of foaming |

| Oxygen Exposure | Minimal, preserves beverage quality | Higher, potential oxidation risk |

| Equipment Complexity | Complex, requires pressure regulation | Simple, less expensive setup |

| Cost | Higher initial investment and maintenance | Lower cost, easy to maintain |

Introduction to Beverage Filling Methods

Isobaric filling and gravity filling are two common methods used in beverage packaging to ensure product quality and shelf life. Isobaric filling maintains equal pressure inside the container and filling system, minimizing carbonation loss and preserving effervescence in carbonated drinks. Gravity filling relies on the natural force of gravity to fill containers, making it suitable for still beverages but less effective for carbonated products due to potential foaming and oxygen ingress.

What is Isobaric Filling?

Isobaric filling is a method used in beverage packaging where both the container and the liquid are pressurized to the same level before filling, minimizing foaming and preserving carbonation. This technique ensures a consistent fill while maintaining the quality and taste of carbonated drinks such as beer and sparkling water. Your beverages benefit from reduced oxidation and improved shelf life compared to gravity filling methods.

How Gravity Filling Works

Gravity filling uses the natural force of gravity to pour liquid products into containers, typically relying on the height difference between the liquid source and the fill point. This method is ideal for thin, non-carbonated liquids due to its simplicity and cost-effectiveness, allowing your production line to run efficiently without complex machinery. Unlike isobaric filling, gravity filling does not require pressurization, making it less suitable for carbonated or highly viscous products.

Key Differences Between Isobaric and Gravity Filling

Isobaric filling maintains consistent pressure throughout the process, ensuring precise liquid volume control and minimizing foam formation, while gravity filling relies on the natural flow of liquid due to gravity, which can result in variable fill levels and greater foam production. Isobaric filling systems are ideal for carbonated beverages due to their ability to preserve carbonation, whereas gravity filling is typically suited for still liquids with lower viscosity. Your choice between these methods depends on product characteristics, production speed requirements, and packaging accuracy.

Applications of Isobaric Filling

Isobaric filling is widely used in the beverage and pharmaceutical industries where maintaining product integrity and preventing oxidation are crucial. This method ensures consistent filling pressure, allowing delicate liquids like carbonated drinks and sterile solutions to be filled without compromising quality. Isobaric filling is preferred for packaging sensitive products such as juices, dairy, and aseptic liquids, enhancing shelf life and product stability compared to gravity filling.

Applications of Gravity Filling

Gravity filling is widely used in applications involving thin, free-flowing liquids such as water, oils, and light beverages due to its simplicity and cost-effectiveness. Your production line benefits from gravity filling when dealing with non-viscous liquids that do not require precise filling speed or pressure control. Common industries utilizing gravity filling include food and beverage, pharmaceuticals, and cosmetics where bottle integrity is less sensitive to pressure fluctuations.

Advantages of Isobaric Filling

Isobaric filling offers precise product dosing by maintaining constant pressure, reducing foam formation and minimizing product oxidation, which ensures superior quality and longer shelf life. It provides enhanced control for carbonated beverages, preventing carbonation loss commonly seen in gravity filling methods. This technique also improves efficiency by reducing product spillage and waste, resulting in cost savings for manufacturers.

Benefits of Gravity Filling

Gravity filling offers precise control over liquid flow rates, reducing foam formation and product waste compared to isobaric filling. This method excels in handling low-viscosity liquids, ensuring gentle product treatment and maintaining quality integrity. Gravity filling systems are cost-effective and simpler to maintain, making them ideal for a variety of beverages and liquid food products.

Choosing the Right Filling Method: Factors to Consider

Selecting the appropriate filling method depends on product viscosity, carbonation level, and container type; isobaric filling suits carbonated beverages by maintaining pressure to prevent foaming, while gravity filling works best for still liquids with lower viscosity. Factors such as production speed, product sensitivity, and sanitation requirements also influence the choice, with isobaric systems often requiring more complex equipment but offering higher accuracy. Understanding these parameters ensures optimal fill quality, reduced product loss, and improved operational efficiency in beverage packaging.

Isobaric vs Gravity Filling: Final Comparison and Recommendations

Isobaric filling maintains consistent pressure throughout the process, ensuring precise volume control and reducing foam formation, which is ideal for carbonated and delicate beverages. Gravity filling relies on the natural flow of liquid due to gravity, offering a simpler and cost-effective solution but with less accuracy and potential for increased oxygen exposure. Your choice depends on product sensitivity and production scale, with isobaric filling recommended for high-quality, carbonated drinks, while gravity filling suits non-carbonated, low-viscosity liquids in smaller batch operations.

Isobaric filling vs gravity filling Infographic

libmatt.com

libmatt.com