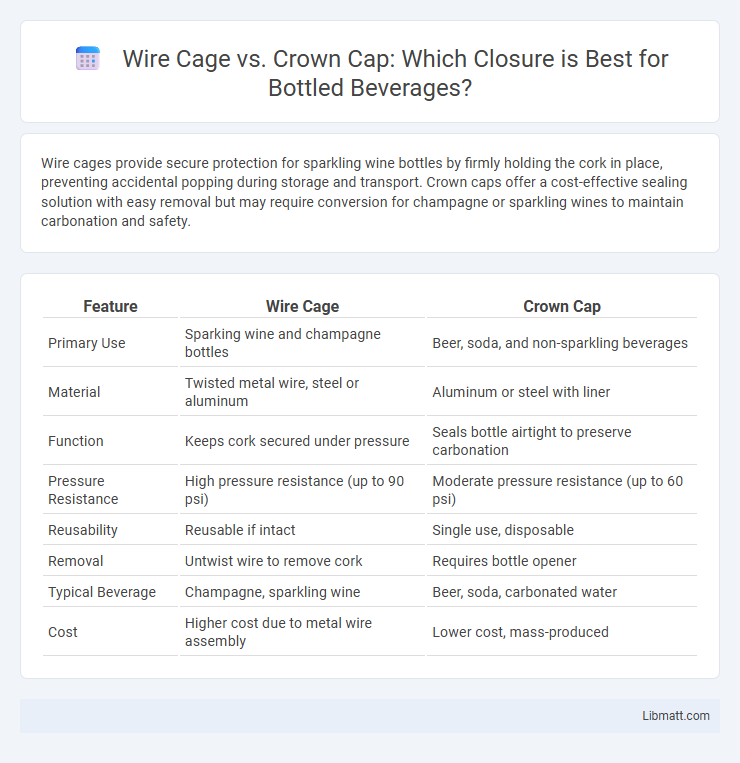

Wire cages provide secure protection for sparkling wine bottles by firmly holding the cork in place, preventing accidental popping during storage and transport. Crown caps offer a cost-effective sealing solution with easy removal but may require conversion for champagne or sparkling wines to maintain carbonation and safety.

Table of Comparison

| Feature | Wire Cage | Crown Cap |

|---|---|---|

| Primary Use | Sparking wine and champagne bottles | Beer, soda, and non-sparkling beverages |

| Material | Twisted metal wire, steel or aluminum | Aluminum or steel with liner |

| Function | Keeps cork secured under pressure | Seals bottle airtight to preserve carbonation |

| Pressure Resistance | High pressure resistance (up to 90 psi) | Moderate pressure resistance (up to 60 psi) |

| Reusability | Reusable if intact | Single use, disposable |

| Removal | Untwist wire to remove cork | Requires bottle opener |

| Typical Beverage | Champagne, sparkling wine | Beer, soda, carbonated water |

| Cost | Higher cost due to metal wire assembly | Lower cost, mass-produced |

Introduction to Wire Cages and Crown Caps

Wire cages secure champagne and sparkling wine corks by tightly holding the mushroom-shaped corks in place under high pressure, preventing accidental popping. Crown caps are metal bottle closures with a corrugated skirt, commonly used for beer and carbonated beverages, providing an airtight seal that maintains carbonation. Both closures ensure beverage freshness and pressure retention but differ in design and typical applications.

Historical Evolution of Bottle Closures

Wire cages, also known as muselets, were developed in the 19th century to secure corks on sparkling wine bottles, preventing cork ejection due to internal pressure. Crown caps, invented in 1892 by William Painter, revolutionized beer and soda packaging by providing a reliable, inexpensive, and easy-to-seal closure method. Your choice between these closures reflects a balance of tradition and practicality rooted in their distinct historical evolution.

Materials and Manufacturing Process

Wire cages are typically made from galvanized steel or stainless steel, shaped through bending and welding processes to fit securely over champagne or sparkling wine bottles. Crown caps, often crafted from aluminum or tinplate steel, are manufactured using stamping and curling techniques to create a tight seal on beer or soda bottles. Your choice between these closures depends on their distinct material properties and production methods, which influence durability and sealing effectiveness.

Design Differences: Wire Cage vs. Crown Cap

Wire cages feature a twisted wire loop securing the cork, primarily used on sparkling wines to withstand internal pressure, while crown caps are metal caps crimped onto the bottle's lip, commonly used for beers and some sparkling beverages. The wire cage allows for controlled removal by untwisting, preserving the cork's integrity, whereas crown caps require a bottle opener and provide a more airtight seal. Design differences impact functionality, with wire cages accommodating expansion pressure and crown caps offering convenience and resealing potential for certain applications.

Application in the Beverage Industry

Wire cages and crown caps serve distinct purposes in the beverage industry, with wire cages primarily securing corks in sparkling wine and champagne bottles to prevent accidental popping due to pressure. Crown caps are predominantly used for sealing beer and carbonated soft drink bottles, ensuring freshness and carbonation retention. Your choice between the two depends on the type of beverage and desired presentation, with wire cages favored for premium sparkling wines and crown caps common in mass-market bottled beverages.

Sealing Effectiveness and Preservation

Wire cages provide strong mechanical support ensuring the cork remains securely in place, enhancing sealing effectiveness and preventing oxidation. Crown caps offer an airtight seal that preserves freshness by minimizing oxygen exposure, ideal for beverages requiring longer shelf life. Your choice impacts preservation quality, with wire cages excelling in traditional sparkling wines and crown caps favored for consistent sealing in craft beers.

Ease of Use and Consumer Experience

Wire cages offer straightforward application and removal, making them user-friendly for securing sparkling wine bottles without special tools. Crown caps provide a tight seal and quick removal but often require a bottle opener, which may impact convenience during casual consumption. Your choice between wire cage and crown cap will influence how easily you can enjoy and serve your beverage.

Cost Comparison and Economic Impact

Wire cages generally incur higher costs due to their intricate manufacturing process and durable materials, making them a pricier option compared to crown caps. Crown caps are widely used in mass production because of their lower material expenses and faster application methods, which significantly reduce overall bottling costs. The economic impact favors crown caps for large-scale beverage industries aiming to optimize packaging budgets while wire cages are preferred for premium sparkling wine products where cost is secondary to presentation and safety.

Environmental Considerations and Recycling

Wire cages are primarily made of steel, which is highly recyclable and often accepted in metal recycling programs, minimizing environmental impact. Crown caps, usually aluminum or steel, are lightweight and easily collected in metal recycling streams, enabling efficient material recovery and reducing landfill waste. Choosing the appropriate closure can influence your environmental footprint, as both options support circular economy practices but vary in recyclability depending on local waste management systems.

Choosing the Right Closure for Your Product

Selecting the right closure for your product depends on factors like beverage type, carbonation level, and presentation. Wire cages provide secure containment for sparkling wines and champagnes, ensuring pressure retention and safety during transport, while crown caps are ideal for beer and carbonated soft drinks, offering a cost-effective, airtight seal. Understanding your product's storage conditions and shelf life helps you determine whether a wire cage or crown cap best preserves quality and enhances consumer appeal.

Wire cage vs crown cap Infographic

libmatt.com

libmatt.com