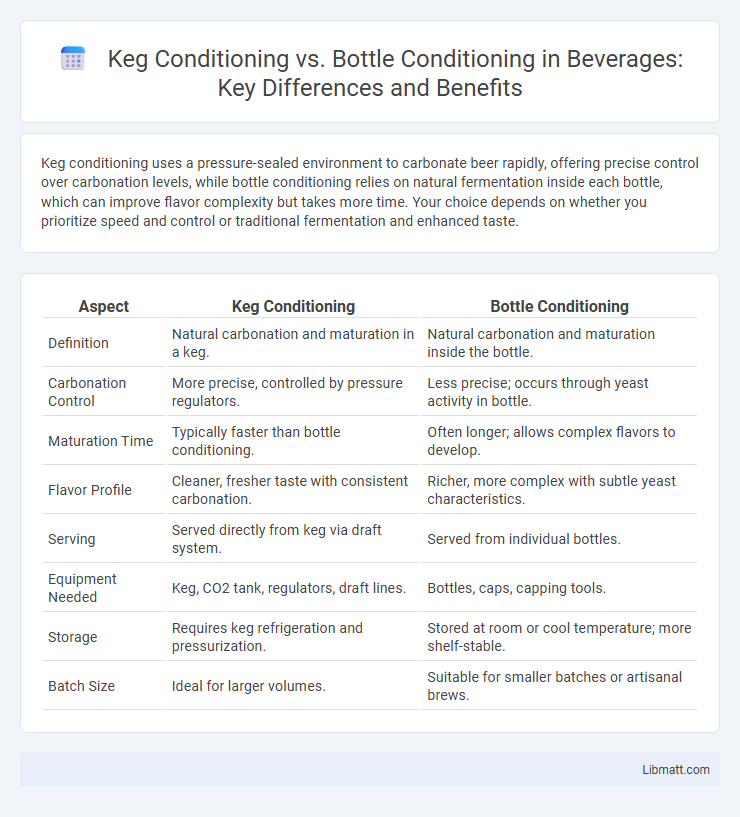

Keg conditioning uses a pressure-sealed environment to carbonate beer rapidly, offering precise control over carbonation levels, while bottle conditioning relies on natural fermentation inside each bottle, which can improve flavor complexity but takes more time. Your choice depends on whether you prioritize speed and control or traditional fermentation and enhanced taste.

Table of Comparison

| Aspect | Keg Conditioning | Bottle Conditioning |

|---|---|---|

| Definition | Natural carbonation and maturation in a keg. | Natural carbonation and maturation inside the bottle. |

| Carbonation Control | More precise, controlled by pressure regulators. | Less precise; occurs through yeast activity in bottle. |

| Maturation Time | Typically faster than bottle conditioning. | Often longer; allows complex flavors to develop. |

| Flavor Profile | Cleaner, fresher taste with consistent carbonation. | Richer, more complex with subtle yeast characteristics. |

| Serving | Served directly from keg via draft system. | Served from individual bottles. |

| Equipment Needed | Keg, CO2 tank, regulators, draft lines. | Bottles, caps, capping tools. |

| Storage | Requires keg refrigeration and pressurization. | Stored at room or cool temperature; more shelf-stable. |

| Batch Size | Ideal for larger volumes. | Suitable for smaller batches or artisanal brews. |

Introduction to Keg Conditioning and Bottle Conditioning

Keg conditioning involves fermenting beer directly in the keg by adding a controlled amount of sugar or yeast, allowing natural carbonation to develop, which results in faster conditioning and easier control over carbonation levels. Bottle conditioning is a traditional method where beer is bottled with added priming sugar and yeast, enabling secondary fermentation in the bottle to carbonate the beer naturally over weeks. Both methods rely on yeast activity to create carbonation but differ in their equipment needs, timeframes, and carbonation consistency.

The Science Behind Conditioning Methods

Keg conditioning relies on controlled carbonation through the addition of priming sugar or CO2 injection, allowing precise pressure regulation and consistent carbonation levels. Bottle conditioning depends on natural fermentation inside the sealed bottle, where residual yeast converts sugars into CO2, creating carbonation and contributing to complex flavor development. Your choice between these methods influences the beer's carbonation uniformity, flavor profile, and aging potential based on the underlying biochemical and physical processes.

Key Differences Between Keg and Bottle Conditioning

Keg conditioning involves fermenting and carbonating beer inside a keg, resulting in faster carbonation and easier pressure control compared to bottle conditioning, where carbonation occurs naturally inside each bottle over time. Bottle conditioning enhances flavor complexity and shelf stability through extended yeast activity, while keg conditioning offers greater convenience for large batches and draft dispensing. Your choice depends on desired carbonation precision, aging time, and serving method preferences.

Equipment Needed for Each Conditioning Process

Keg conditioning requires a CO2 tank, pressure regulator, and a keg with a spunding valve or a way to capture natural carbonation, making it suitable for faster carbonation and better control of pressure. Bottle conditioning necessitates bottling equipment, such as bottles, caps or corks, and priming sugar to enable natural fermentation inside each bottle for carbonation. Both methods demand sanitation tools, but keg conditioning involves more specialized draft system components, while bottle conditioning relies on individual packaging materials.

Flavor Development: Kegs vs. Bottles

Keg conditioning allows for more consistent and controlled carbon dioxide levels, which preserves hop aroma and enhances fresh, clean flavors. Bottle conditioning enables natural carbonation through yeast fermentation, contributing to complex flavor profiles and slight variations due to continued yeast activity. Flavor development in kegs tends to emphasize crispness and clarity, while bottles often offer richer, evolving tastes over time.

Carbonation Levels and Control

Keg conditioning allows for precise control over carbonation levels by adjusting CO2 pressure, ensuring consistent and tailored carbonation throughout the keg. Bottle conditioning relies on natural fermentation with added sugar, producing variable carbonation levels that can fluctuate between bottles due to yeast activity. Brewers seeking uniform carbonation and quick serving prefer keg conditioning, while bottle conditioning offers traditional effervescence and complexity.

Timeframe: Which Method is Faster?

Keg conditioning typically takes less time than bottle conditioning, with carbonation usually achieved within 1 to 2 weeks due to controlled pressure and temperature. Bottle conditioning can require 2 to 4 weeks, as yeast slowly carbonates the beer in each individual bottle. Faster turnaround in kegging is ideal for brewers prioritizing efficiency and consistent carbonation.

Consistency and Quality in the Final Product

Keg conditioning offers more consistent carbonation and flavor stability due to controlled pressure and temperature, reducing oxidation risks compared to bottle conditioning. Bottle conditioning can introduce variability as yeast activity and sugar levels differ per bottle, affecting the taste and carbonation over time. For Brewers seeking reliability in Your final product, keg conditioning ensures uniform quality across batches.

Suitability for Homebrewing and Commercial Brewing

Keg conditioning is ideal for commercial brewing due to its efficiency, consistent quality control, and ease of large-scale distribution, while bottle conditioning suits homebrewing by allowing natural carbonation through yeast fermentation inside individual bottles. Your choice depends on the scale and desired flavor complexity; bottle conditioning fosters nuanced, naturally carbonated profiles but requires longer maturation and careful monitoring. Commercial brewers prioritize keg conditioning for rapid turnaround and uniformity, whereas homebrewers value bottle conditioning for hands-on craftsmanship and traditional brewing practices.

Choosing the Best Method for Your Beer

Keg conditioning offers precise control over carbonation levels, making it ideal for brewers seeking consistent quality and faster fermentation times. Bottle conditioning develops natural carbonation through yeast fermentation in the bottle, enhancing complex flavors and providing traditional presentation but requires longer aging. Selecting between keg and bottle conditioning depends on factors such as desired carbonation control, aging time, and serving preferences for your beer.

Keg conditioning vs bottle conditioning Infographic

libmatt.com

libmatt.com