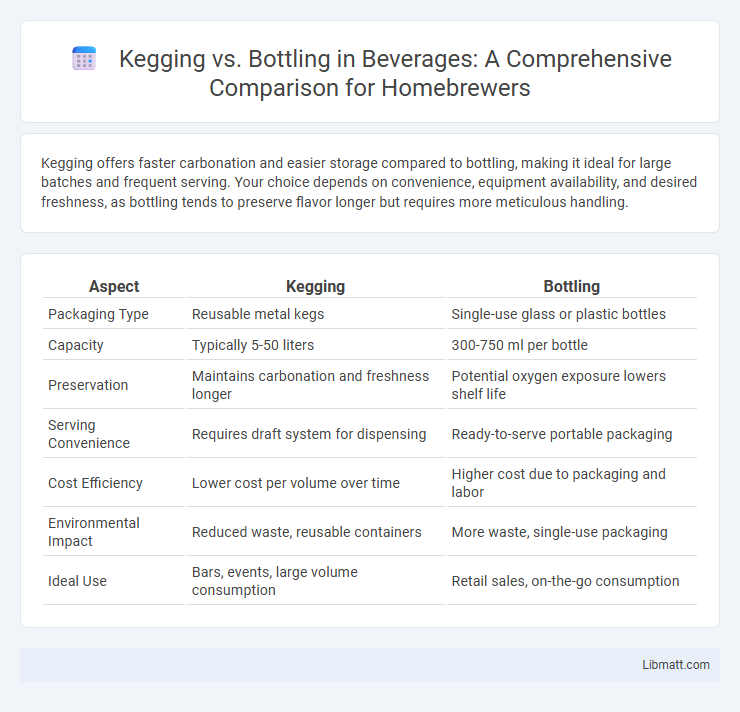

Kegging offers faster carbonation and easier storage compared to bottling, making it ideal for large batches and frequent serving. Your choice depends on convenience, equipment availability, and desired freshness, as bottling tends to preserve flavor longer but requires more meticulous handling.

Table of Comparison

| Aspect | Kegging | Bottling |

|---|---|---|

| Packaging Type | Reusable metal kegs | Single-use glass or plastic bottles |

| Capacity | Typically 5-50 liters | 300-750 ml per bottle |

| Preservation | Maintains carbonation and freshness longer | Potential oxygen exposure lowers shelf life |

| Serving Convenience | Requires draft system for dispensing | Ready-to-serve portable packaging |

| Cost Efficiency | Lower cost per volume over time | Higher cost due to packaging and labor |

| Environmental Impact | Reduced waste, reusable containers | More waste, single-use packaging |

| Ideal Use | Bars, events, large volume consumption | Retail sales, on-the-go consumption |

Introduction to Kegging and Bottling

Kegging and bottling are two common methods for packaging and storing beverages such as beer and cider. Kegging involves transferring the liquid into stainless steel kegs that maintain carbonation and freshness through pressurized CO2. Bottling, on the other hand, uses glass or plastic bottles sealed with caps or corks, often allowing for longer shelf stability but requiring careful sanitation to prevent contamination.

Key Differences Between Kegging and Bottling

Kegging involves storing beer in large pressurized containers, allowing for easier carbonation control and faster dispensing, while bottling requires filling individual bottles, which can be more time-consuming and prone to oxidation. Kegs maintain beer freshness longer due to minimal oxygen exposure, whereas bottled beer may degrade quicker once opened or improperly sealed. The equipment investment and cleaning requirements differ, with kegging demanding specialized tap systems and more rigorous sanitation compared to the simplicity of bottling setups.

Equipment Needed for Kegging

Kegging requires specific equipment such as a sanitized keg, CO2 tank, regulator, and proper tubing to maintain carbonation and freshness. Your setup must include a keg coupler compatible with your keg type to ensure efficient dispensing. Compared to bottling, kegging streamlines the packaging process and reduces oxidation risks, requiring investment in durable and reusable gear.

Equipment Needed for Bottling

Bottling requires specific equipment such as a bottling bucket, bottle filler, capping machine, and sanitized bottles to ensure proper packaging and preservation of beer. Unlike kegging, where kegs and CO2 regulators dominate, bottling necessitates additional tools for filling and sealing each individual bottle. Proper sanitization and precise filling equipment minimize oxidation and contamination risks during the bottling process.

Time and Effort Involved

Kegging significantly reduces time and effort compared to bottling by allowing brewers to fill, seal, and carbonate beer in one streamlined process, eliminating the need for individual bottle cleaning, filling, and capping. Bottling requires extensive preparation, including sanitizing dozens of bottles, manually filling each one, capping, and labeling, which can be labor-intensive and time-consuming. Keg systems facilitate faster turnaround and easier cleanup, making them ideal for those seeking efficiency in homebrewing or small-scale production.

Cost Comparison: Kegging vs Bottling

Kegging generally offers lower long-term costs compared to bottling due to reusable kegs that eliminate continuous bottle and cap purchases. While initial investment in kegs and dispensing equipment is higher, your expenses decrease significantly over multiple batches. Bottling incurs ongoing costs for bottles, caps, and labeling, making it more expensive per batch despite lower upfront setup fees.

Beer Quality and Flavor Preservation

Kegging maintains beer quality and flavor preservation by minimizing oxygen exposure and limiting light contact, which reduces oxidation and spoilage risks compared to bottling. The airtight environment in kegs helps retain carbonation levels and fresh taste for longer periods. In contrast, bottles may allow slight oxygen ingress and light exposure, potentially leading to flavor degradation over time.

Cleaning and Maintenance Requirements

Kegging requires regular cleaning of kegs, valves, and lines to prevent contamination and maintain beer quality, often involving specialized equipment for thorough sanitation. Bottling demands meticulous sterilization of bottles, caps, and bottling machinery to avoid oxidation and spoilage, with extra attention to removing residues and ensuring airtight seals. Both methods necessitate consistent maintenance routines, but kegging typically allows for faster, more efficient cleaning cycles compared to the labor-intensive bottling process.

Ideal Scenarios for Kegging

Kegging is ideal for breweries or homebrewers who prioritize efficiency and freshness, especially when serving larger volumes at once. It suits environments where controlled carbonation and faster dispensing are essential, such as bars, restaurants, or events. Your beer's taste remains consistent over time, making kegging perfect for maintaining quality during extended storage or frequent pours.

Ideal Scenarios for Bottling

Bottling is ideal for small-batch brewing where portability and long-term storage are priorities, allowing for easy distribution and individual servings. It suits scenarios with limited draft equipment or where beer needs to be transported to events, stores, or consumers. Bottling also offers better control over carbonation levels and shelf stability for a variety of beer styles.

Kegging vs bottling Infographic

libmatt.com

libmatt.com