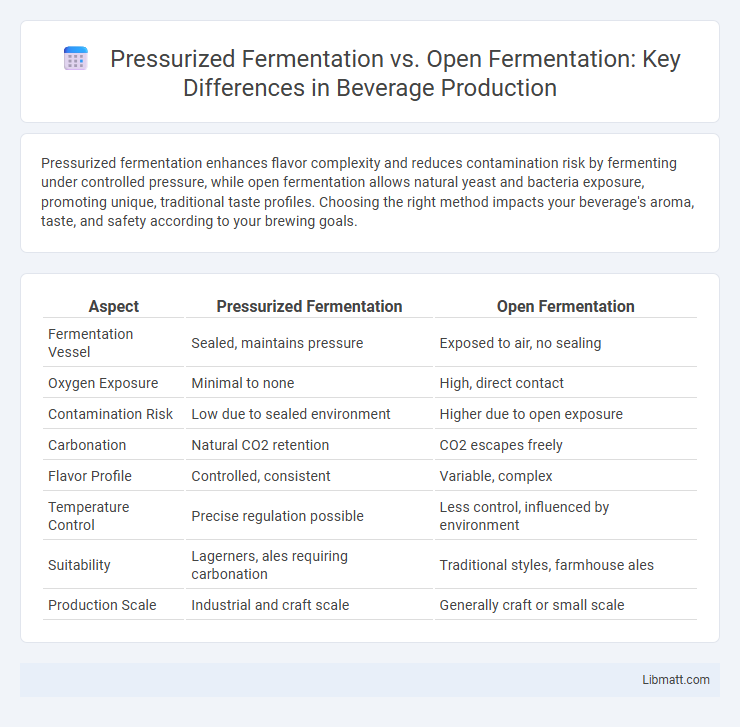

Pressurized fermentation enhances flavor complexity and reduces contamination risk by fermenting under controlled pressure, while open fermentation allows natural yeast and bacteria exposure, promoting unique, traditional taste profiles. Choosing the right method impacts your beverage's aroma, taste, and safety according to your brewing goals.

Table of Comparison

| Aspect | Pressurized Fermentation | Open Fermentation |

|---|---|---|

| Fermentation Vessel | Sealed, maintains pressure | Exposed to air, no sealing |

| Oxygen Exposure | Minimal to none | High, direct contact |

| Contamination Risk | Low due to sealed environment | Higher due to open exposure |

| Carbonation | Natural CO2 retention | CO2 escapes freely |

| Flavor Profile | Controlled, consistent | Variable, complex |

| Temperature Control | Precise regulation possible | Less control, influenced by environment |

| Suitability | Lagerners, ales requiring carbonation | Traditional styles, farmhouse ales |

| Production Scale | Industrial and craft scale | Generally craft or small scale |

Introduction to Fermentation Methods

Pressurized fermentation utilizes sealed vessels that maintain elevated pressure, enhancing microbial activity and increasing yield efficiency compared to open fermentation, which occurs in non-airtight containers and allows more exposure to contaminants. Open fermentation is commonly used in traditional brewing methods where natural fermentation profiles are desired, while pressurized fermentation is preferred in industrial settings for consistent quality and faster production cycles. Your choice between these methods depends on the desired flavor complexity, production scale, and contamination control requirements.

What Is Open Fermentation?

Open fermentation is a traditional brewing method where the fermenting vessel is exposed to the environment, allowing natural yeast and bacteria to interact with the brew. This process enhances the complexity and unique flavors of your beer but increases the risk of contamination due to airborne microbes. Unlike pressurized fermentation, open fermentation provides less control over temperature and pressure, impacting the final taste and aroma profile.

What Is Pressurized Fermentation?

Pressurized fermentation involves maintaining increased pressure in the fermentation vessel to enhance yeast activity and flavor development, resulting in faster fermentation and improved aroma retention. In contrast, open fermentation exposes the batch to atmospheric conditions, allowing wild yeast and bacteria interaction but increasing contamination risk. Your choice between pressurized and open fermentation affects the control over fermentation kinetics, consistency, and product quality in brewing or winemaking processes.

Historical Overview of Fermentation Practices

Pressurized fermentation dates back to innovative advances in the 19th century, revolutionizing brewing by allowing better control over carbonation and flavor profiles through sealed fermentation tanks. Open fermentation, with roots tracing back thousands of years, relies on exposed vessels, often used in traditional brewing cultures for its natural yeast interaction and distinctive taste development. Understanding these historical practices helps you appreciate how fermentation techniques evolved to balance flavor consistency and production efficiency.

Key Differences Between Open and Pressurized Fermentation

Open fermentation exposes the brew to ambient air, allowing natural yeast and bacteria to influence the fermentation process, while pressurized fermentation occurs in sealed vessels that maintain specific pressure levels, controlling CO2 retention and flavor profiles. Open fermentation often results in more complex, sometimes unpredictable flavors due to airborne microbes, whereas pressurized fermentation produces cleaner, crisper brews with consistent carbonation and reduced oxidation risks. Understanding these key differences helps you choose the ideal fermentation method based on desired taste, production scale, and control over fermentation variables.

Impact on Flavor Profiles

Pressurized fermentation enhances your beer's flavor profile by retaining volatile compounds, resulting in cleaner, smoother, and often fruitier notes compared to open fermentation, which permits more oxidation and wild yeast activity, contributing to complex, sour, and funky flavors. The controlled environment of pressurized fermentation limits exposure to oxygen and contaminants, preserving delicate esters and phenols critical for refined taste. Open fermentation encourages natural yeast behavior and microbial diversity, producing bold, tangy, and rustic characteristics favored in traditional ales and sour beers.

Microbial Control and Contamination Risks

Pressurized fermentation offers enhanced microbial control by maintaining a sealed environment that minimizes oxygen exposure and contamination risks from airborne microorganisms. Open fermentation exposes the culture to ambient air, increasing vulnerability to unwanted microbial contamination and requiring stringent sanitation protocols. Effective microbial control in pressurized systems results in more consistent product quality and reduced risk of batch failures.

Equipment and Cost Considerations

Pressurized fermentation requires specialized, reinforced fermenters capable of withstanding high internal pressures, which significantly increases initial capital expenditure compared to open fermentation setups that use simple, open vessels. Equipment for pressurized fermentation is typically made from stainless steel with advanced pressure regulation systems, leading to higher maintenance and operational costs. Open fermentation equipment is more cost-effective and easier to clean but may result in higher contamination risks and inconsistent product quality, impacting your overall production efficiency.

Applications in Modern Brewing

Pressurized fermentation enhances control over yeast activity and reduces contamination risks, making it ideal for high-alcohol and lager beer production in modern breweries. Open fermentation remains prevalent in traditional and craft brewing, especially for styles like Belgian ales, where natural air exposure and unique microbial contributions are desired. Both methods influence flavor profiles and production scalability, with pressurized systems enabling consistency and open fermentation fostering complex, nuanced beers.

Choosing the Right Fermentation Method

Pressurized fermentation maintains a controlled environment, enhancing yeast performance and increasing ethanol yield, making it ideal for high-alcohol beer or biofuel production. Open fermentation, characterized by exposure to ambient air, promotes diverse microbial populations and unique flavor profiles, preferred in traditional Belgian ales and sour beers. Choosing between pressurized and open fermentation depends on desired product characteristics, contamination risk tolerance, and process consistency requirements.

Pressurized fermentation vs open fermentation Infographic

libmatt.com

libmatt.com